A method for producing 1,3-propanediol by fermentation of glycerol

A technology of propylene glycol and glycerol, applied in the field of bioengineering, can solve the problems of high energy consumption, low fermentation level, and many fermentation by-products, etc., and achieves the effects of low energy consumption, prolonging the fermentation period, and reducing the separation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Strain cultivation: Take 70mL of activated Klebsiella bacteria liquid, mix it with 630mL seed medium in a 1L fermenter, and carry out micro-aerobic culture with a ventilation rate of 0.02vvm; the culture conditions are: the culture temperature is 37°C, The stirring speed was 200 rpm, the pH was controlled at 7.0, and the fermented seed liquid was obtained after culturing for 18 hours.

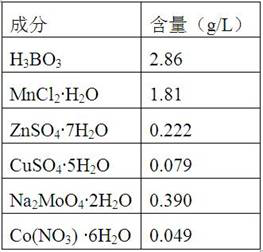

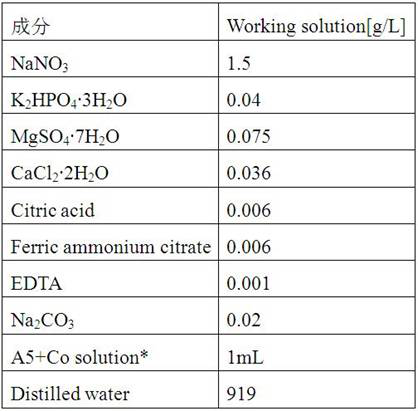

[0043] (2) Microalgae culture: Mix 60mL of algae liquid of cellulosic algae SS-B7 in the logarithmic growth phase and 540mL of microalgae medium in a column reactor (40mm in inner diameter, 500mm in height), and CO2 is introduced during the cultivation process. 2 Air mixture with a content of 3v%, light intensity of 4000Lux, culture temperature of 28°C, pH value of 7.5, light cycle of 24h, light-to-dark time ratio of 14:10, cultivated until the algae cells in the microalgae seed liquid are dry. The weight reaches 18.2g / L.

[0044] (3) Fermentation process: The volume of the fermente...

Embodiment 2

[0048] (1) Strain cultivation: Take 70mL of activated Klebsiella bacteria liquid, mix it with 630mL seed culture medium in a 1L fermenter, and carry out micro-aerobic culture with an air intake of 0.06vvm; the culture conditions are: the culture temperature is 37 °C, the stirring speed is 300 rpm, the pH is controlled at 7.2, and the fermented seed liquid is obtained after culturing for 18 hours.

[0049] (2) Microalgae cultivation: Mix 30mL of algae liquid of cellulosic algae SS-B7 in the logarithmic growth phase and 570mL of medium in a column reactor (inner diameter 40mm, height 500mm), and CO2 is introduced during the cultivation process. 2 The content of air mixture is 10v%, the light intensity is 7000Lux, the culture temperature is 37°C, the pH value is controlled at 7.5, the light cycle is 24h, and the light-dark time ratio is 16:8. The weight reaches 19.6g / L.

[0050] (3) Fermentation process: The volume of the fermenter is 15L, and the liquid volume is 7L.

[0051] ...

Embodiment 3

[0054] The fermentation process and process conditions are the same as in Example 1. The difference is that the pH is adjusted to 7.5 after the microalgae seed solution is added during the fermentation process.

[0055] After 40 hours of fermentation, the detected 1,3-propanediol concentration was 78.2g / L, the acetic acid concentration was 4.6g / L, and the conductivity was 16.8mS / cm. End the fermentation, adjust the pH to 8.5, let it stand for 8 hours, the fermentation broth is separated, and the supernatant is OD 600 、OD 280 The detection values were 1.0 and 10.6, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com