Low-surface-energy titanium heating wire as well as preparation method and application thereof

A heating wire and titanium wire technology, applied in the field of electronic cigarette materials, can solve the problems of e-liquid gelatinization and the like, and achieve the effects of reducing e-liquid adhesion, simple preparation method, and reducing the amount of adhesion and carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

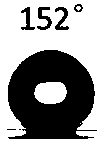

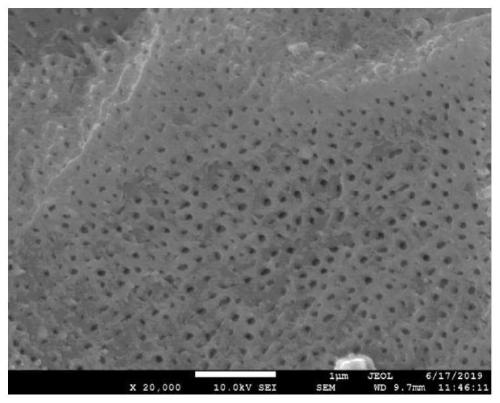

[0028] The titanium wire was ultrasonically cleaned with acetone, ethanol and deionized water in turn, and air-dried with nitrogen, and then the titanium wire was placed in 0.5wt% ammonium fluoride in ethylene glycol solution, using it as an anode and applying a voltage of 10V while stirring status response for 10 minutes. After the completion, take out the titanium heating wire, rinse the solution on it with deionized water, and then dry the water in a blast drying oven to obtain a titanium wire with an anodic oxidation layer. Such as figure 1 As shown, the micro-nanopore structure on it.

[0029] Preparation of sol-gel coating: Add 30ml of ethanol, 0.9ml of glacial acetic acid, 2ml of n-hexanol, 5ml of HCl (0.01M), 5ml of methyltriethoxysilane, and 0.5ml of KH550 in a three-necked flask, and stir at room temperature Mix evenly, then add 0.2 g of deionized water, stir for 24 hours, and age at room temperature for 7 days to obtain a sol-gel solution with uniform appearance. ...

Embodiment 2

[0036] As in Example 1, a voltage of 100V was applied.

[0037] Preparation of sol-gel coating: Add ethanol 30ml, glacial acetic acid 0.9ml, n-hexanol 2ml, HCl (0.01M) 5ml, methyltriethoxysilane 5ml, dimethyldimethoxysilane 0.2ml, 0.5ml of KH550, 1ml of perfluorodecylethyltriethoxysilane, stirred and mixed evenly at room temperature, then added 0.2g of deionized water, stirred for 24h, and aged for 7 days at room temperature to obtain the sol-gel glue solution.

[0038] Dilute the obtained sol-gel solution 100 times with absolute ethanol, dip-coat the titanium wire with anodized layer, dry it at room temperature, and then treat it in an oven at 180°C for 3 hours to obtain the titanium heating wire .

[0039] The test results are similar to Example 1.

Embodiment 3

[0041] As in Example 1, a voltage of 60V was applied.

[0042] Preparation of sol-gel coating: Add ethanol 30ml, glacial acetic acid 0.9ml, n-hexanol 2ml, HCl (0.01M) 5ml, methyltriethoxysilane 5ml, dimethyldimethoxysilane 0.5ml, KH550 is 0.5ml, stir and mix evenly at room temperature, then add 0.2g of deionized water, stir for 24h, and age at room temperature for 7 days to obtain a sol-gel solution with a uniform appearance.

[0043]Dilute the obtained sol-gel solution 100 times with absolute ethanol, dip-coat the titanium wire with anodized layer, dry it at room temperature, and then treat it in an oven at 180°C for 3 hours to obtain the titanium heating wire .

[0044] The test results are similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com