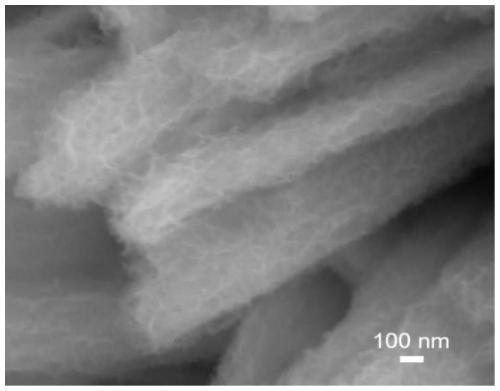

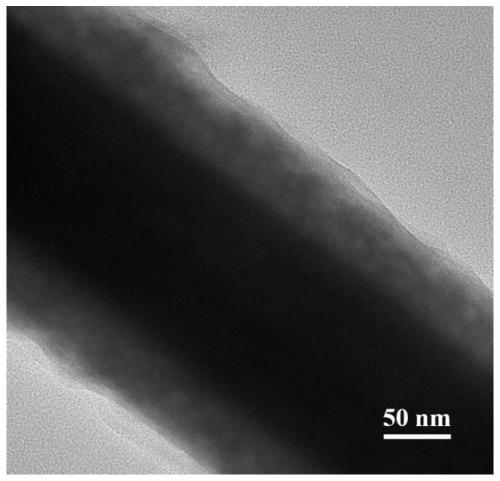

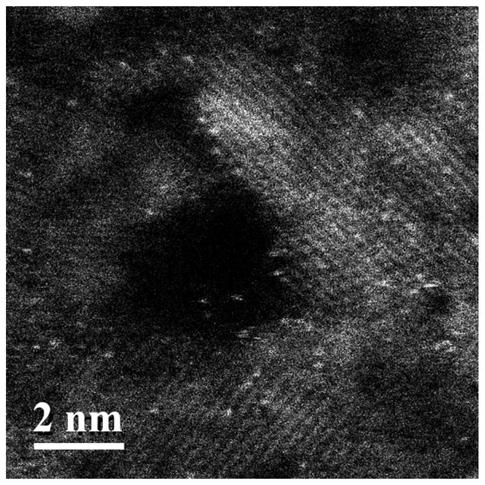

Tungsten-doped nickel selenide sulfide film-coated nickel selenide sulfide nanorod growing on surface of foamed nickel and preparation method and application of nickel selenide sulfide nanorod

A technology of film wrapping and nickel selenide, which is applied in the field of new material technology and chemical synthesis, can solve the problem of large specific surface energy of single atoms, and achieve the effect of promoting electrochemical performance, convenient operation, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1, take the selenium powder with a concentration of 5.76g / L, and dissolve the selenium powder with a hydrazine hydrate solution concentration of 2.5mol / L. At this time, mechanically stir at a speed of 1200r / min for 30min at room temperature to obtain a selenium source mixed solution , add thiourea concentration to be 5.56g / L, ammonium fluoride concentration be 8g / L and tungsten trioxide concentration be 11.13g / L in the above-mentioned selenium source mixed solution, then add 15mL dehydrated alcohol concentration to be 4mol / L and 9ml Deionized water was mechanically stirred at room temperature at a speed of 1200r / min for 30min to obtain a mixed solution;

[0031] Step 2: Activate the surface of the foamed nickel, take the foamed nickel and place it in acetone, alcohol, and deionized water for ultrasonic cleaning for 20 minutes, take out the foamed nickel and soak it in an acid solution for 6 hours, and place it in deionized water for 20 minutes after taking it out an...

Embodiment 2

[0046] Step 1, taking by weighing a concentration of 2.88g / L selenium dioxide, taking a hydrazine hydrate solution concentration of 1.5mol / L to dissolve selenium dioxide, at this time, mechanically stirring at a speed of 600r / min for 20min at room temperature to obtain a selenium source Mixed solution, adding thiourea concentration to the above-mentioned selenium source mixed solution is 8.34g / L, ammonium fluoride concentration is 10g / L and sodium tungstate concentration is 2g / L, then adds 12mL dehydrated alcohol concentration and is 3mol / L and 15ml of deionized water was mechanically stirred at room temperature at a speed of 600r / min for 20min to obtain a mixed solution;

[0047] Step 2, surface activation treatment of the foamed nickel, take the foamed nickel and place it in acetone, alcohol, and deionized water for ultrasonic cleaning for 5 minutes, take out the foamed nickel and place it in an acid solution for 12 hours, take it out and place it in deionized water for ultra...

Embodiment 3

[0052] Step 1, taking by weighing concentration is 8.64g / L selenocystine, and getting hydrazine hydrate solution concentration is 5mol / L to dissolve selenocystine, at this moment, carry out mechanical stirring 40min with the rotating speed of 1600r / min at room temperature, Obtain the selenium source mixed solution, add thiourea concentration to the above-mentioned selenium source mixed solution and be 2.78g / L, ammonium fluoride concentration be 10mol / L and ammonium tungstate concentration be 2g / L, then add 15mL dehydrated alcohol concentration and be 6mol / L and 5ml deionized water, mechanically stirred at room temperature at a speed of 1600r / min for 40min to obtain a mixed solution;

[0053] Step 2: Activate the foamed nickel surface, take the foamed nickel and place it in acetone, alcohol, and deionized water for ultrasonic cleaning for 40 minutes, take out the foamed nickel and soak it in an acid solution for 0.5 hours, take it out and place it in deionized water for ultraso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com