Flame-retardant curing agent containing phosphazene/aromatic imine composite structure and preparation method thereof

A technology of aromatic imine and composite structure, which is applied in the field of flame retardant processing aids, can solve problems such as poor compatibility and decline in material comprehensive performance, and achieve excellent flame retardant performance, reduced dosage, and excellent intrinsic flame retardant performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

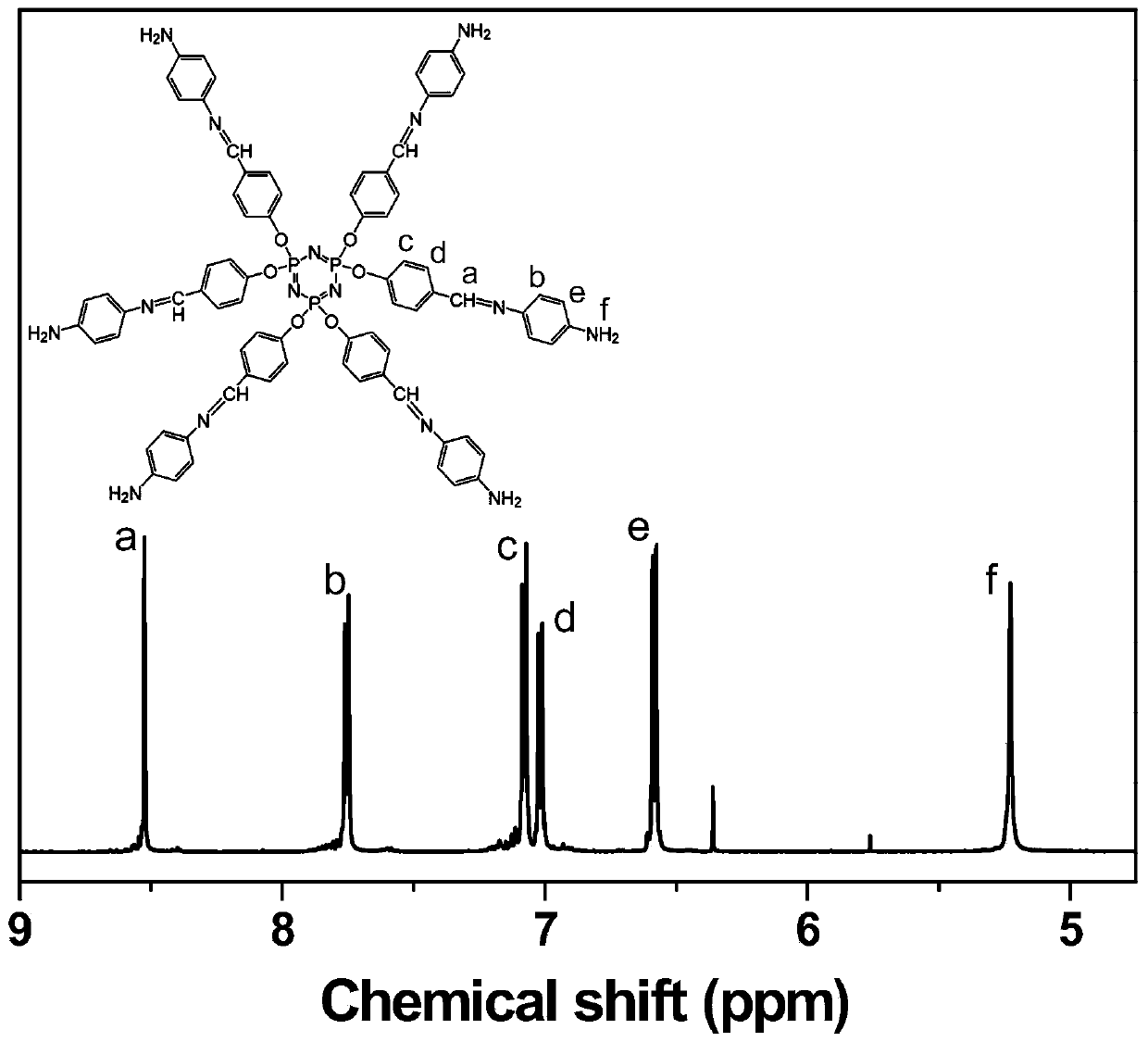

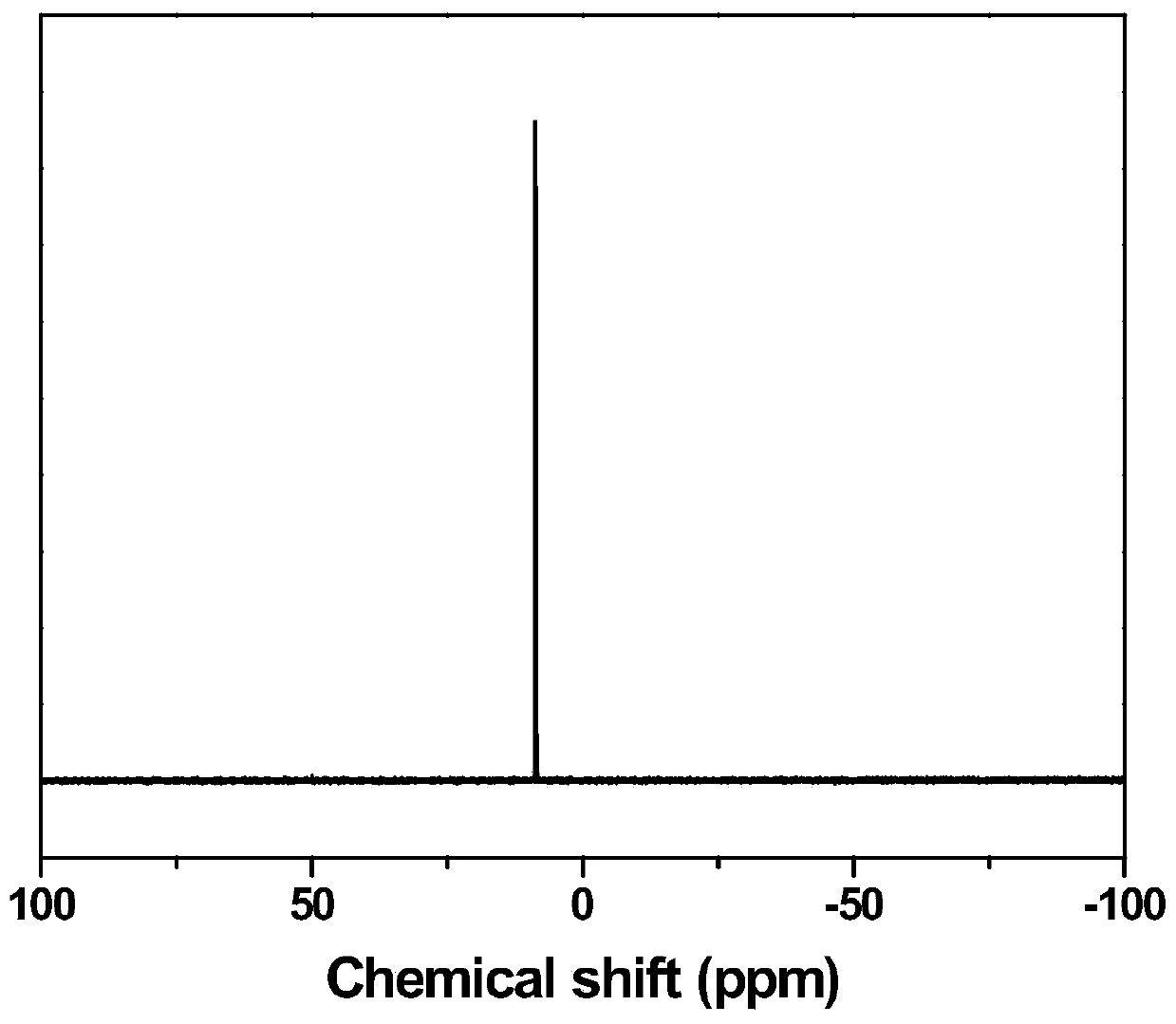

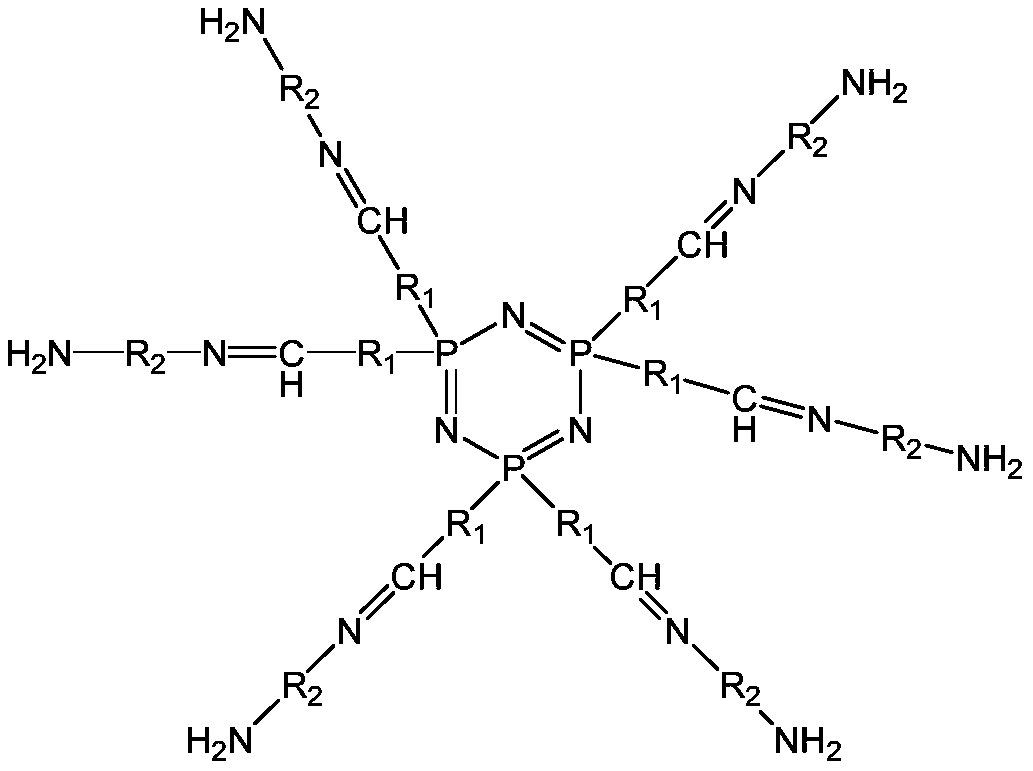

Method used

Image

Examples

Embodiment 1

[0031] The preparation steps of the intermediate product: add 130g of p-hydroxybenzaldehyde, 100g of triethylamine, 54g of hexachlorocyclotriphosphazene, and 300mL of 1,4-dioxane into a magnetic stirring, condensing and reflux device, constant pressure drop Funnel and a nitrogen-protected 1L three-neck round-bottomed flask, after complete dissolution, the temperature was raised to 90°C, the reaction was continued for 12 hours, and cooled to room temperature. Then, it was filtered, concentrated by rotary evaporation, poured into 1 L of deionized water for precipitation, stirred at room temperature for 1 hour, filtered, washed with 300 ml of ethanol several times, and dried in vacuo to obtain a crude product. Purify by recrystallization with ethyl acetate to obtain 116.2 g of intermediate product with a yield of 90.3%.

[0032] Preparation steps of flame retardant curing agent: Add 75g of p-phenylenediamine and 100mL of 1,4-dioxane into a 500mL three-neck round bottom flask with...

Embodiment 2

[0036] Put 130g of salicylaldehyde, 41g of sodium hydroxide, 54g of hexachlorocyclotriphosphazene, and 300mL of tetrahydrofuran into a 1L three-necked round-bottomed flask with magnetic stirring, a condensation reflux device, a constant pressure dropping funnel, and nitrogen protection, and wait until completely After dissolving, the temperature was raised to 65°C, and the reaction was carried out for 48 hours, and then cooled to room temperature. Then concentrated by rotary evaporation, poured into 1L of deionized water for reverse phase precipitation, stirred at room temperature for 1 hour, filtered, washed with 300ml of ethanol for several times, and dried in vacuo to obtain a crude product. Recrystallization and purification with ethyl acetate gave 113.6 g of intermediate product with a yield of 85%.

[0037]Add 80g of 2,3-diaminopyridine and 200mL of tetrahydrofuran into a 500mL three-necked round-bottom flask equipped with magnetic stirring, condensing reflux device, and...

Embodiment 3

[0040] Add 100g of 3-ethoxy-4-hydroxybenzaldehyde (ethyl vanillin), 27g of sodium hydroxide, and 200mL of tetrahydrofuran into a 500mL three-neck tank with magnetic stirring, condensing reflux device, constant pressure dropping funnel and nitrogen protection. In the round-bottomed flask, heat up to 65°C, add 80ml of tetrahydrofuran solution containing 35g of hexachlorocyclotriphosphazene within 1 hour after complete dissolution, and cool to room temperature after reacting for 24 hours. Then concentrated by rotary evaporation, poured into 1L deionized water for precipitation, stirred at room temperature for 1 hour, filtered, washed with 300ml ethanol for several times, and dried in vacuo to obtain a crude product. Further recrystallization from ethyl acetate gave 102.3 g of intermediate product with a yield of 90.1%.

[0041] Add 70g of p-phenylenediamine into a 500mL three-necked round-bottomed flask equipped with magnetic stirring, condensing reflux device, and constant press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com