Process for extracting and purifying high-quality tea polyphenol by using spherical polyamide resin

A technology of polyamide resin and tea polyphenols, which is applied in the direction of organic chemistry, can solve the problems of long production cycle, large amount of solvent, and difficult separation, and achieve high and stable purification and extraction rate, simple and convenient separation method, and excellent chromatographic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A process for extracting and purifying high-quality tea polyphenols with a spherical polyamide resin, comprising the following method steps:

[0026] Extraction: crush the dried tea leaves through a 0.5mm sieve, extract with hot water for 1-1.5h, the number of extractions is three times, the water temperature is 80°C, and the solid-to-liquid ratio is W:V=5;

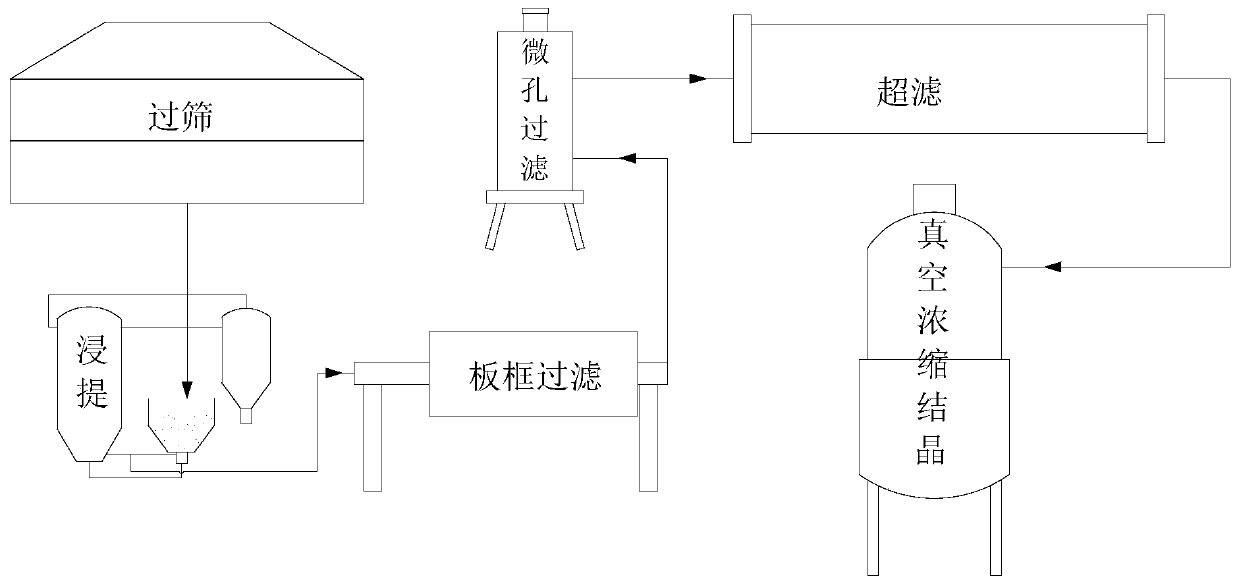

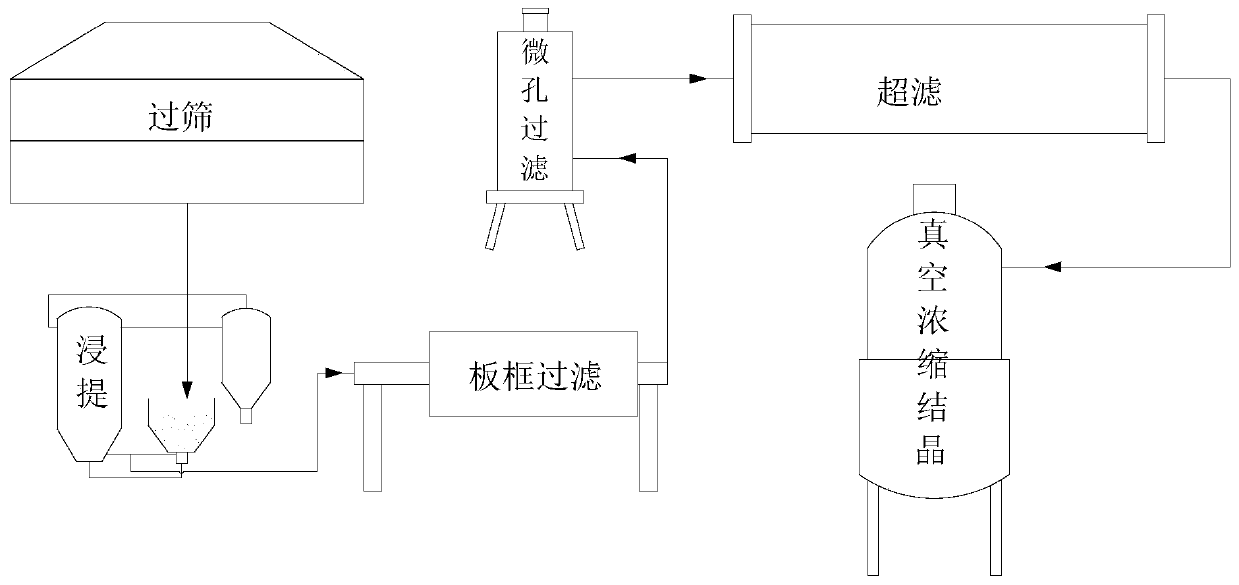

[0027] Filtration: The extract is passed through a plate-and-frame filter, a microporous filter, and an ultrafilter respectively. The mesh number of the plate-and-frame filter is 400 mesh, and the aperture of the microporous filter is 0.5um. The molecular weight is 100,000, and the tea extract fine filtrate is obtained by solid-liquid separation;

[0028] Chromatography: pump the fine filtrate of the tea extract obtained by filtration into a chromatographic column equipped with HST-PA spherical polyamide chromatographic resin at a flow rate of 3CV / h for chromatographic adsorption. The eluent washes away caffeine a...

Embodiment 2

[0031] A process for extracting and purifying high-quality tea polyphenols with a spherical polyamide resin, comprising the following method steps:

[0032] Extraction: crush the dried tea leaves through a 0.5mm sieve, extract with hot water for 1-1.5h, the number of extractions is three times, the water temperature is 90°C, and the solid-to-liquid ratio is W:V=6;

[0033] Filtration: The extract is passed through a plate-and-frame filter, a microporous filter, and an ultrafilter respectively. The mesh number of the plate-and-frame filter is 400 mesh, and the aperture of the microporous filter is 0.5um. The molecular weight is 100,000, and the tea extract fine filtrate is obtained by solid-liquid separation;

[0034] Chromatography: pump the fine filtrate of the tea extract obtained by filtration into a chromatography column equipped with HST-PA spherical polyamide chromatographic resin at a flow rate of 4CV / h for adsorption. The citric acid water has a pH value of 2.5, the e...

Embodiment 3

[0037] A process for extracting and purifying high-quality tea polyphenols with a spherical polyamide resin, comprising the following method steps:

[0038] Extraction: crush the dried tea leaves through a 0.5mm sieve, extract with hot water for 1-1.5h, the number of extractions is three times, the water temperature is 100°C, and the solid-to-liquid ratio is W:V=10;

[0039] Filtration: The extract is passed through a plate-and-frame filter, a microporous filter, and an ultrafilter respectively. The mesh number of the plate-and-frame filter is 400 mesh, and the aperture of the microporous filter is 0.5um. The molecular weight is 100,000, and the tea extract fine filtrate is obtained by solid-liquid separation;

[0040] Chromatography: Pump the fine filtrate of the tea extract obtained by filtration into a chromatography column equipped with HST-PA spherical polyamide chromatographic resin at a flow rate of 3CV / h for adsorption. The citric acid water has a pH value of 4.0, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com