Preparation method of perovskite thin film with introduced with capsaicine

A thin film preparation, perovskite technology, applied in final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc. Humidity, oxygen sensitivity and other issues, to achieve the effect of increased size, low cost, mild and controllable reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Preparation of PTAA film

[0020] Dissolve PTAA and F4TCNQ with a mass ratio of 4:1 in chlorobenzene, dissolve at 60°C, prepare a chlorobenzene solution with a PTAA content of 2mg / ml as a spin coating solution, heat and dissolve at 60°C Filter it into a spin-coating solution, drop it on the conductive glass substrate (ITO), spin-coat at a speed of 5000 rpm for 30 seconds, then place it on a heating platform at 150°C, and anneal for 10 minutes to obtain a PTAA film, spin-coat DMF solvent improves its wettability.

[0021] (2) Preparation of perovskite precursor

[0022] Weigh 1.08 mol of lead iodide and 1 mol of methyl iodide, dissolve in 750 microliters of N,N-dimethylformamide and 85 microliters of dimethyl sulfoxide mixed solvent, and form a precursor solution after fully dissolving .

[0023] (3) Preparation of perovskite thin films

[0024] The perovskite precursor solution was added dropwise on the PTAA film, spin-coated at 4000 rpm for 30 seconds, 150 micr...

Embodiment 2

[0029] (1) Preparation of PTAA film

[0030] With embodiment 1.

[0031] (2) Preparation of perovskite precursor

[0032] Weigh 1.08 mol of lead iodide and 1 mol of methyl iodide, dissolve in 750 microliters of N,N-dimethylformamide and 85 microliters of dimethyl sulfoxide mixed solvent, and add a mass ratio of 0.01wt% The capsaicin is fully dissolved to form a precursor solution.

[0033] (3) Preparation of perovskite thin films

[0034] With embodiment 1.

Embodiment 3

[0036] (1) Preparation of PTAA film

[0037] With embodiment 1.

[0038] (2) Preparation of perovskite precursor

[0039] Weigh 1.08 mol of lead iodide and 1 mol of methyl iodide, dissolve in 750 microliters of N,N-dimethylformamide and 85 microliters of dimethyl sulfoxide mixed solvent, add 0.1wt% Capsaicin is fully dissolved to form a precursor solution.

[0040] (3) Preparation of perovskite thin films

[0041] With embodiment 1.

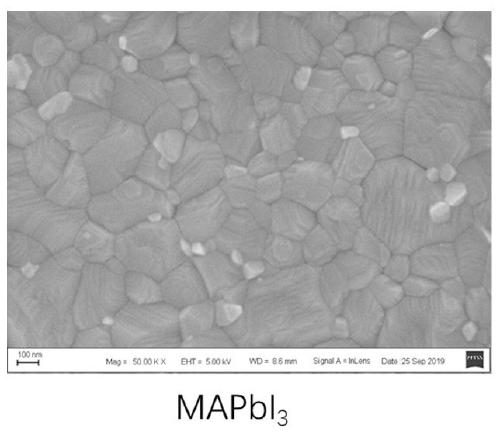

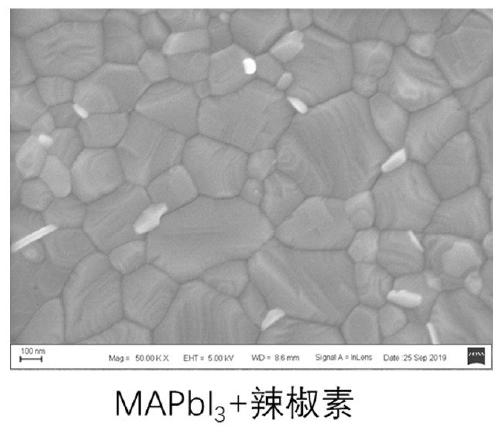

[0042] See attached figure 2 , the perovskite film prepared above is characterized by electronic scanning, the perovskite film is flat and compact, and the grain size becomes significantly larger, indicating that the introduced capsaicin can effectively increase the perovskite grain size.

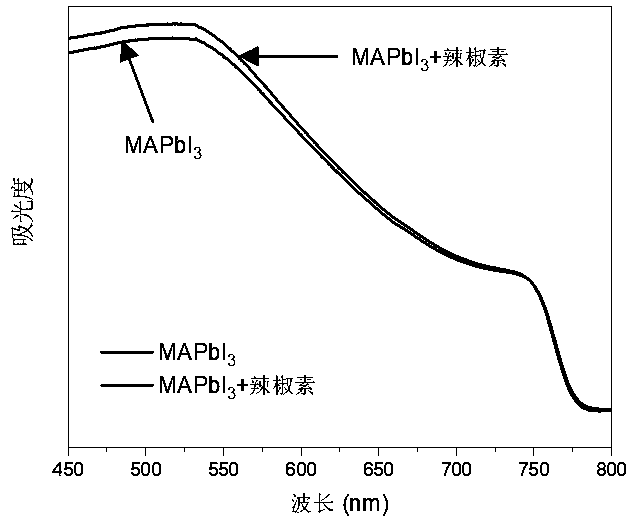

[0043] See attached image 3 , the perovskite film prepared above was found by spectral absorption, and the absorption intensity was also significantly improved after the introduction of capsaicin, which was consistent with the increase in grain size. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com