Preparation technology and application for Agaricus blazei Murill. dietary fiber

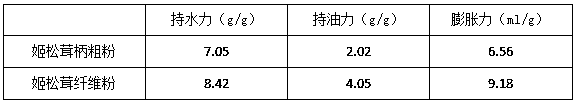

A dietary fiber and preparation technology, applied in the field of food processing, can solve the problems of difficult development and utilization, poor palatability, high fiber content, etc., and achieve the effects of high SDF content, good oil holding power, and high content of high-quality dietary fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]A preparation process of Agaricus blazei dietary fiber, comprising the following steps:

[0037] 1. Take fresh Agaricus blazei stalks, wash away impurities, and then dry them at 40°C until the moisture content is 6-8%;

[0038] 2. Pulverize the dried Agaricus blazei stalk and pass through a 100-mesh sieve to obtain Agaricus blazei stalk coarse powder;

[0039] 3. Use an equidistant single-screw extruder to oligomerize the coarse powder of Agaricus blazei blazei, and the extrusion conditions are: the extrusion temperature is 160°C, and the liquid-solid mass ratio is 1.4:1 to obtain the fine powder of Agaricus blazei blazei shank;

[0040] 4. Mix Agaricus blazei fine powder and water at a material-to-liquid ratio of 1:4, and add 2% skimmed milk powder and 1.5% white sugar to the mixture, mix the material evenly, and adjust the pH to 4.5~6.5 After sterilization within the range, then add 3% Trichoderma reesei seed liquid (0.5*10 8 CFU / ml), adjust the temperature within 28...

Embodiment 2

[0060] A preparation process of Agaricus blazei dietary fiber, comprising the following steps:

[0061] 1. Take fresh Agaricus blazei stalks, wash away impurities, and then dry them at 40°C until the moisture content is 6-8%;

[0062] 2. Pulverize the dried Agaricus blazei stalk and pass through a 150-mesh sieve to obtain Agaricus blazei stalk coarse powder;

[0063] 3. Use an equidistant twin-screw extruder to oligomerize the coarse powder of Agaricus blazei stipe, the extrusion conditions are: the extrusion temperature is 160°C, the mass ratio of liquid to solid is 1.5:1, and the fine powder of Agaricus blazei stalk is obtained;

[0064] 4. Mix Agaricus blazei fine powder and water at a material-to-liquid ratio of 1:3, and add 2% skimmed milk powder and 1.5% sucrose to the mixture, mix the material evenly, and adjust the pH to 4.5~6.5 Sterilize after inside, then add 5% Trichoderma reesei seed solution (0.4*10 8 CFU / ml), adjust the temperature within 28~30℃, add 5% Bacillu...

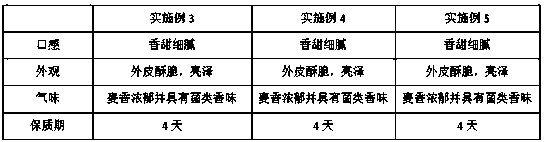

Embodiment 3

[0073] A kind of Agaricus blazei bread prepared by utilizing the Agaricus blazei fiber powder prepared in Example 1, the formula includes the following parts by weight:

[0074] Agaricus blazei fiber powder 20 parts, bread flour 100 parts, sucrose 10 parts, butter 10 parts, 1.5 parts active yeast, 2 parts salt, 1 part sodium caseinate, 1 part glycerol lactic acid fatty acid ester, 50 parts distilled water.

[0075] The preparation method comprises the following steps:

[0076] (1) Mix Agaricus blazei fiber powder, bread flour, and active yeast in the dough mixer at a slow speed for 5 minutes according to the formula ratio, then knead at a medium speed for 15 minutes, and then ferment at 30°C and 75% humidity for 90 minutes;

[0077] (2) Mix sucrose, butter, salt, sodium caseinate, and glycerol lactic acid fatty acid ester in the dough mixer at a slow speed for 3 minutes, and then at a medium speed for 10 minutes. After dividing and cutting blanks, mix them at 30°C and 75°C. P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com