Persulfate activator, preparation method and applications thereof

A technology of persulfate oxidation and persulfate, which is applied in the field of environmental pollutant treatment, can solve the problems of difficult recycling of metal ions, secondary pollution, etc., achieve excellent catalytic activity and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A persulfate activator of the present invention is Ni 2 SnO 4 -RGO, prepared by:

[0035] (1) Put 0.16g of graphite oxide in distilled water to disperse evenly by ultrasonic, the ultrasonic time is 15min, the ultrasonic power is 250W, and the ultrasonic frequency is 40kHz;

[0036] (2) 0.95g NiCl 2 ·6H 2 O and 0.70 g SnCl 4 ·5H 2 O is dissolved in distilled water to form a nickel-tin mixed salt solution;

[0037] (3) adding the mixed salt solution into the graphene oxide dispersion, stirring for 30min to form a metal salt-graphene oxide mixed solution;

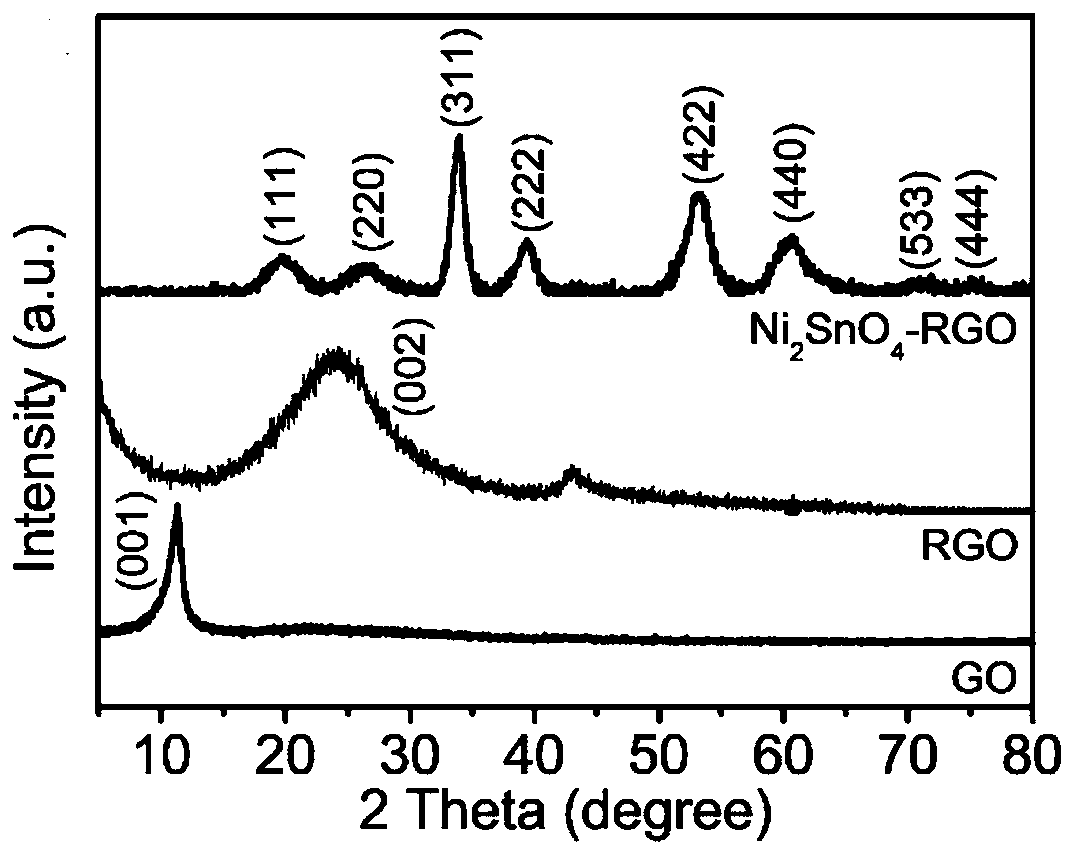

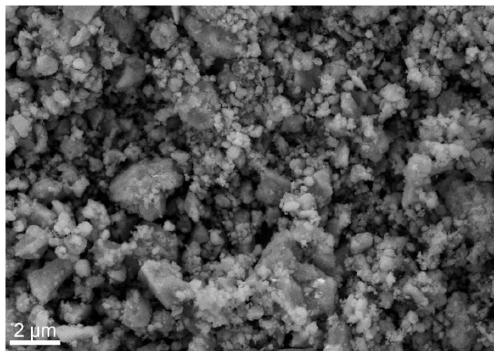

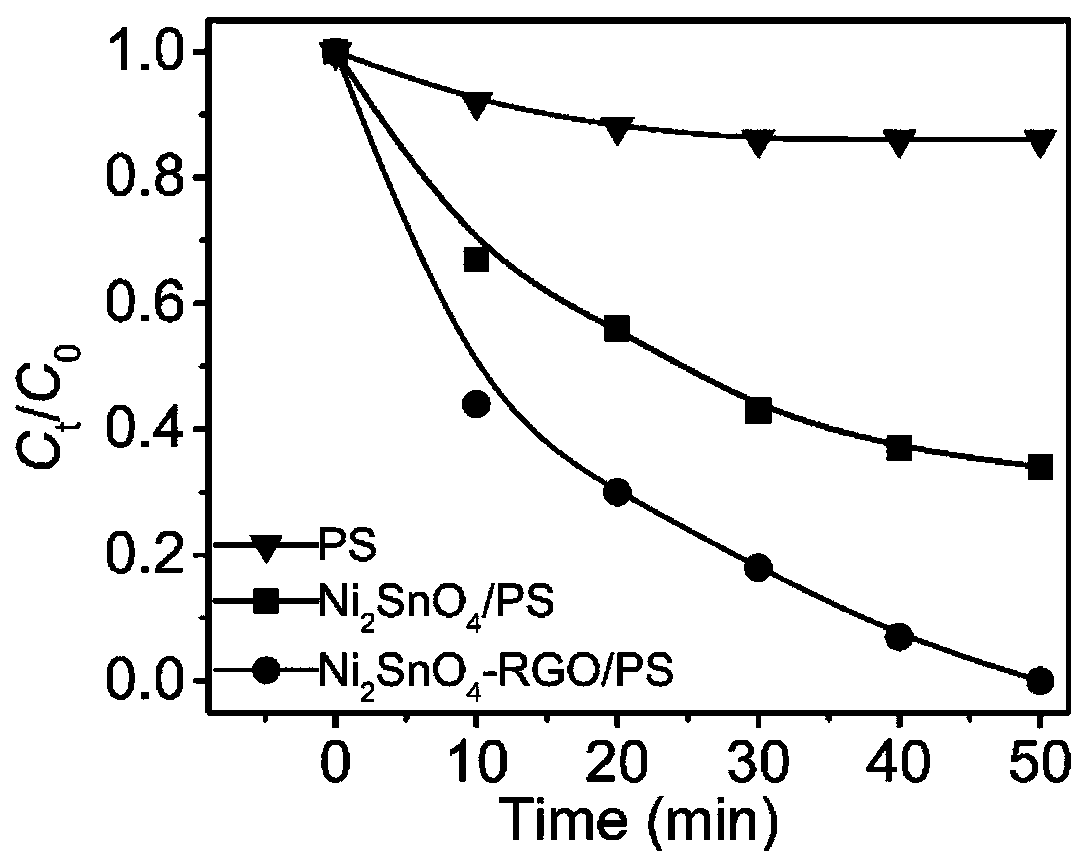

[0038] (4) Use 1M NaOH to adjust the pH of the metal salt-graphene oxide mixture to 9, stir it evenly, and then carry out a hydrothermal reaction at 200°C for 12 hours. After the reaction, cool to room temperature, filter with suction, collect the precipitate, wash it, and wash it at 60 ℃ vacuum drying 12h, obtain the Ni of 0.63g present embodiment 2 SnO 4 - RGO activator. figure 1 Ni in this example2 SnO 4 -...

Embodiment 2

[0040] A persulfate activator of the present invention is Ni 2 SnO 4 -RGO, prepared by:

[0041] (1) 0.16g of graphite oxide is placed in distilled water for ultrasonic dispersion;

[0042] (2) 0.95g NiCl 2 ·6H 2 O and 0.70 g SnCl 4 ·5H 2 O is dissolved in distilled water to form a nickel-tin mixed salt solution;

[0043] (3) adding the mixed salt solution into the graphene oxide dispersion, stirring for 30min to form a metal salt-graphene oxide mixed solution;

[0044] (4) Use 1M NaOH to adjust the pH of the metal salt-graphene oxide mixture to 4. After stirring evenly, carry out a hydrothermal reaction at 200°C for 12 hours. After the reaction is completed, cool to room temperature, filter with suction, collect the precipitate, wash, and dry at 60°C. °C and vacuum dried for 12 h, no brown solid product was obtained.

Embodiment 3

[0046] A persulfate activator of the present invention is Ni 2 SnO 4 -RGO, prepared by:

[0047] (1) 0.16g of graphite oxide is placed in distilled water for ultrasonic dispersion;

[0048] (2) 0.95g NiCl 2 ·6H 2 O and 0.70 g SnCl 4 ·5H 2 O is dissolved in distilled water to form a nickel-tin mixed salt solution;

[0049] (3) adding the mixed salt solution into the graphene oxide dispersion, stirring for 30min to form a metal salt-graphene oxide mixed solution;

[0050] (4) Use 1M NaOH to adjust the pH of the metal salt-graphene oxide mixture to 9, and then carry out a hydrothermal reaction at 180°C for 10 hours after stirring evenly. After the reaction is completed, cool to room temperature, filter with suction, collect the precipitate, wash, After vacuum drying at °C for 12 hours, a brown solid product was obtained, but the yield was very low, only 0.25 g of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com