Embedded alloy catalyst and preparation method and application thereof

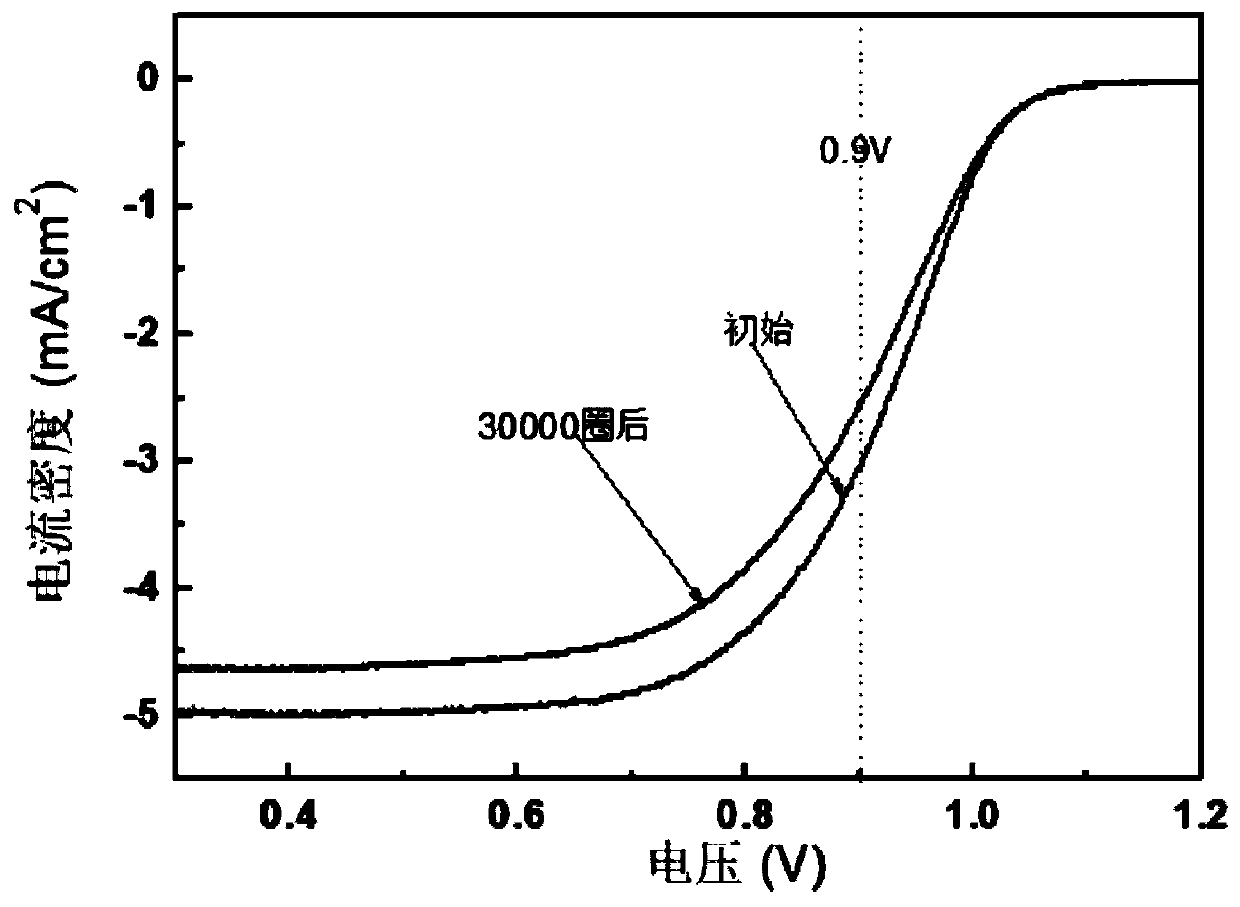

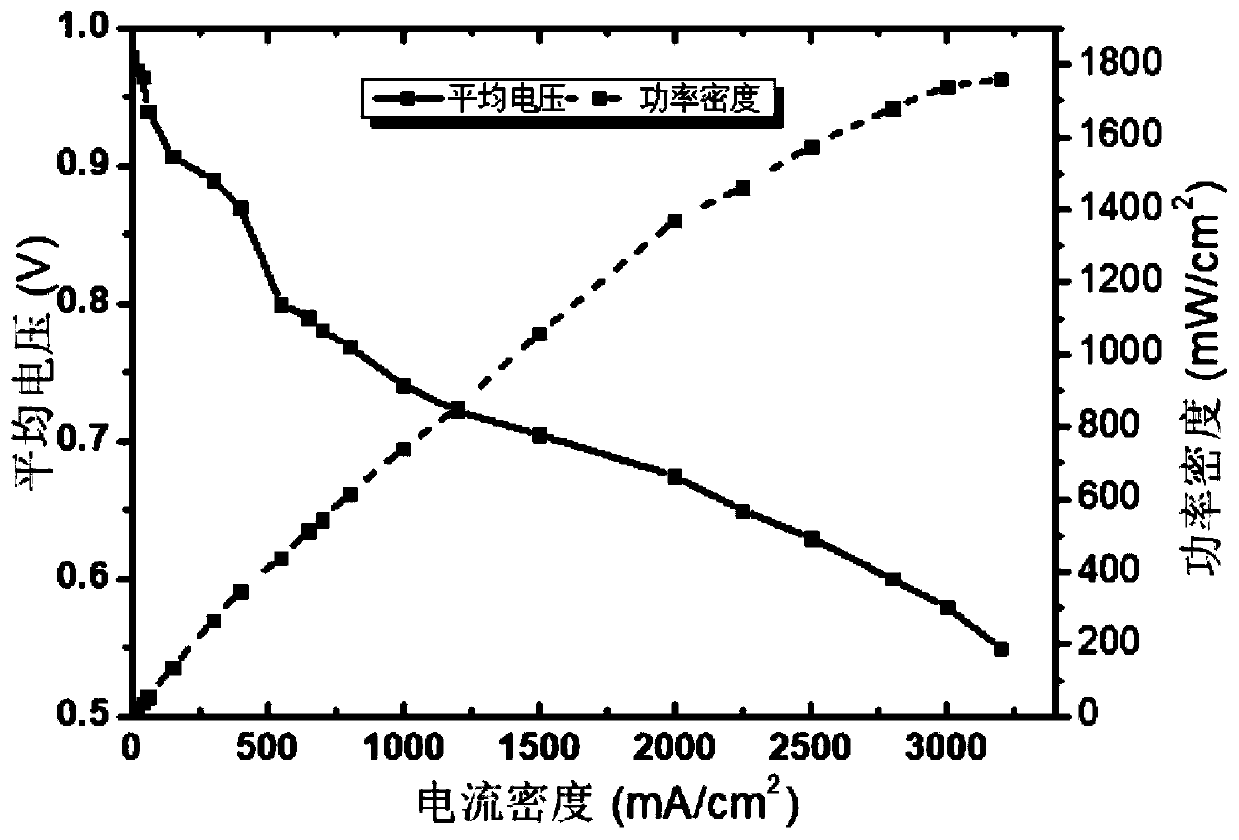

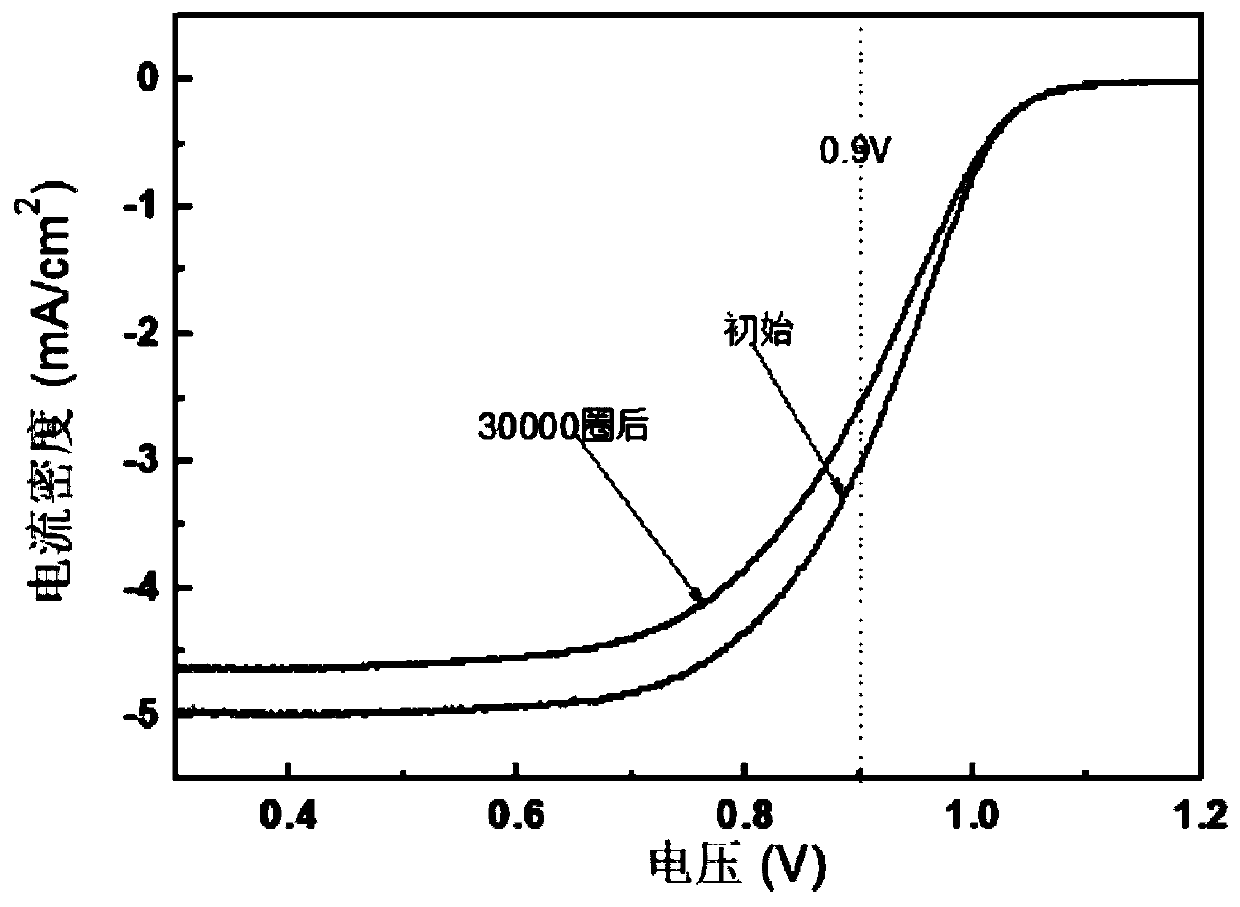

An alloy catalyst and embedded technology, applied in solid electrolyte fuel cells, electrical components, battery electrodes, etc., can solve the problems of high price, low storage capacity of Pt metal, easy poisoning, etc., and achieve improved stability and strong electron affinity The effect of improving the ability and catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The preparation method of embedded alloy catalyst comprises the following steps:

[0065] (1') Weigh 0.01g of Vulcan XC-72 carbon black and place it in a reaction vessel, add 1mL of water to it, then place it in an ultrasonic homogenizer to disperse evenly, and continue ultrasonication for 10min to obtain Vulcan XC-72 carbon black black dispersion;

[0066] (2') Add 50 μL of pyrrole monomer solution (density of 0.967g / mL) into the Vulcan XC-72 carbon black dispersion in step (1'), and continue to stir for 10 minutes to make the pyrrole monomer absorb as much as possible on the The surface of Vulcan XC-72 carbon black, obtain mixed solution;

[0067] (3') Take 670 μL of chloroplatinic acid solution with a platinum element concentration of 0.01 g / mL, and quickly add it to the mixed solution obtained in step (2') under the condition of vigorous stirring, and then continue stirring at room temperature for 10 h, pass The oxidative properties of high-valence Pt make pyrrole...

Embodiment 2

[0074] The preparation method of embedded alloy catalyst comprises the following steps:

[0075] (1') Weigh 10g of Vulcan XC-72 carbon black and place it in a reaction vessel, add 100mL of ethanol to it, then place it in an ultrasonic homogenizer to disperse evenly, and continue ultrasonication for 60min to obtain Vulcan XC-72 carbon black Dispersions;

[0076] (2') Add 2000 μL of aniline monomer solution (with a density of 1.022 g / mL) into the Vulcan XC-72 carbon black dispersion in step (1'), and continue stirring for 60 minutes to make the aniline monomer adsorb as much as possible to the The surface of Vulcan XC-72 carbon black, obtain mixed solution;

[0077] (3') Take 23.3mL of potassium hexachloroplatinate solution with a platinum element concentration of 0.01g / mL, and quickly add it to the mixed solution obtained in step (2') under vigorous stirring, and then continue to Stir for 48 hours, then filter the product with suction, wash it three times with a mixture of N,...

Embodiment 3

[0080] The preparation method of embedded alloy catalyst comprises the following steps:

[0081] (1') Weigh 8 g of Ketjen Black and place it in a reaction vessel, add 60 mL of oleic acid thereto, then place it in an ultrasonic homogenizer to disperse evenly, and continue ultrasonication for 50 minutes to obtain a Ketjen Black dispersion;

[0082] (2') Add 1350 μL 3,4-ethylenedioxythiophene solution (density 1.331g / mL) into the Ketjen Black dispersion in step (1'), and continue stirring for 45 minutes to make 3,4-ethylenedioxythiophene Thiophene is adsorbed onto the surface of Ketjen Black as much as possible to obtain a mixed solution;

[0083] (3') Take 800 μL of potassium tetrachloroplatinate solution with a platinum element concentration of 0.01 g / mL, and quickly add it to the mixed solution obtained in step (2') under vigorous stirring, and then continue stirring at room temperature After 12 hours, the product was suction filtered, rinsed three times with a mixture of n-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Peak power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com