Pollution-free and efficient processing process for preserved fruits with cores

A processing technology and pollution-free technology, applied in the confectionary industry, sugary food ingredients, food freezing, etc., can solve the problems of environmental pollution, loss of fresh fruit nutrients, pollution, etc., to avoid soft rotten pulp, reduce blood sugar load, The effect of improving glucose tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A pollution-free and highly efficient processing technology for nuclei-containing candied fruit, using green plums as raw materials, specifically includes the following steps:

[0035] S1: Selection of raw materials, choose greengage fruit with large round fruit shape, small core, thin skin, and fresh color;

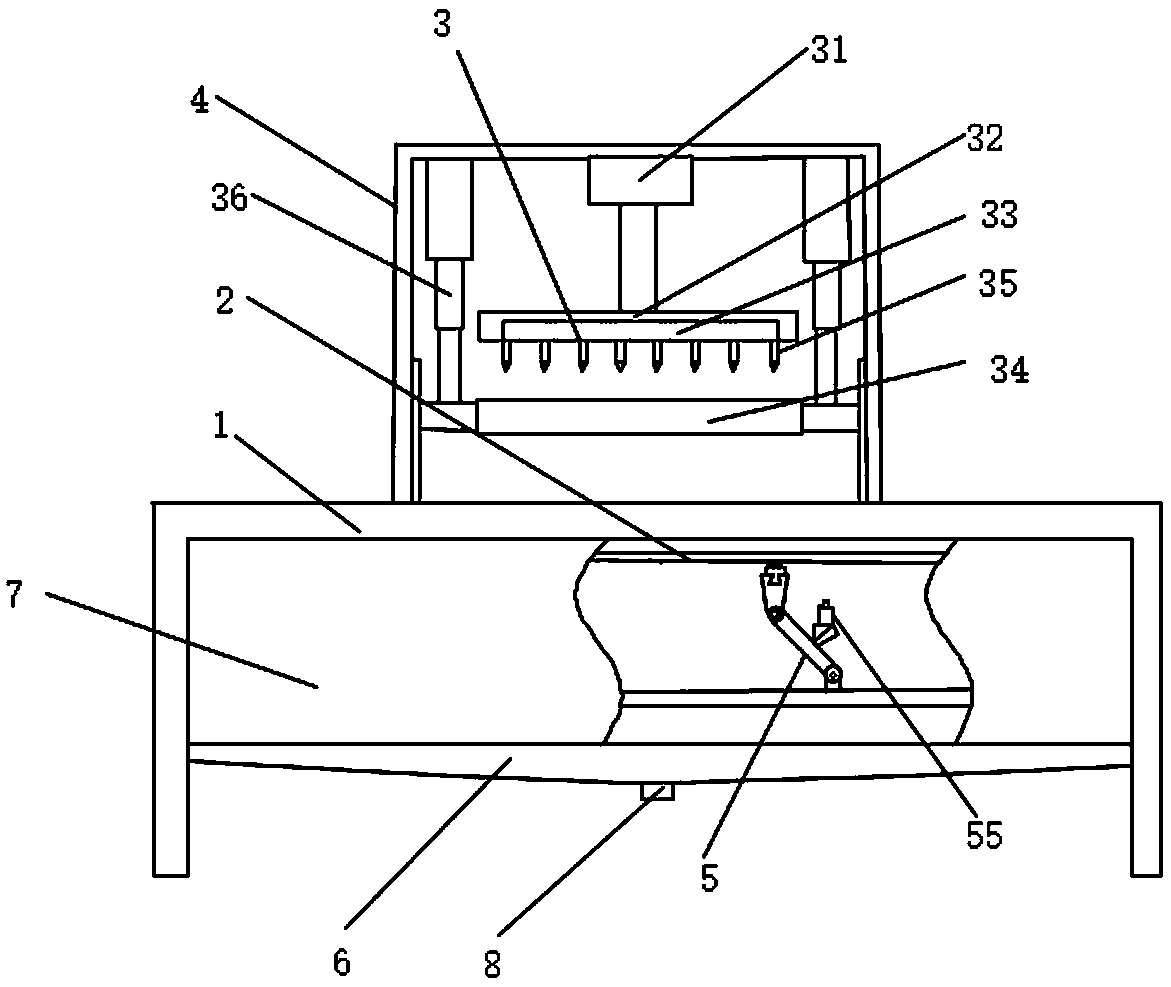

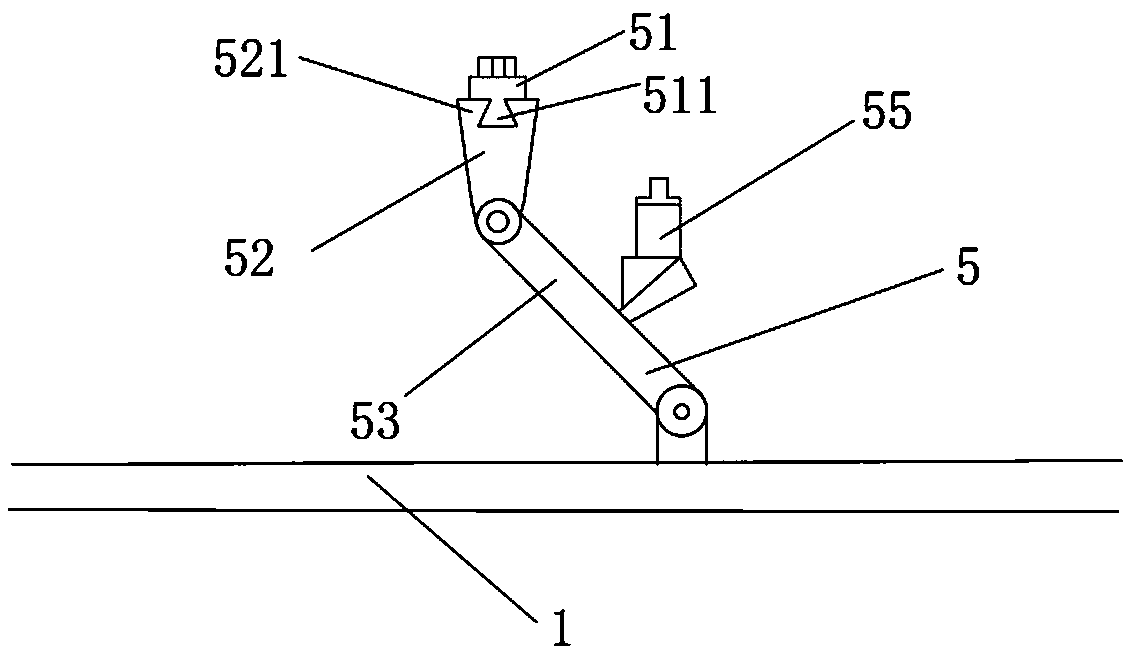

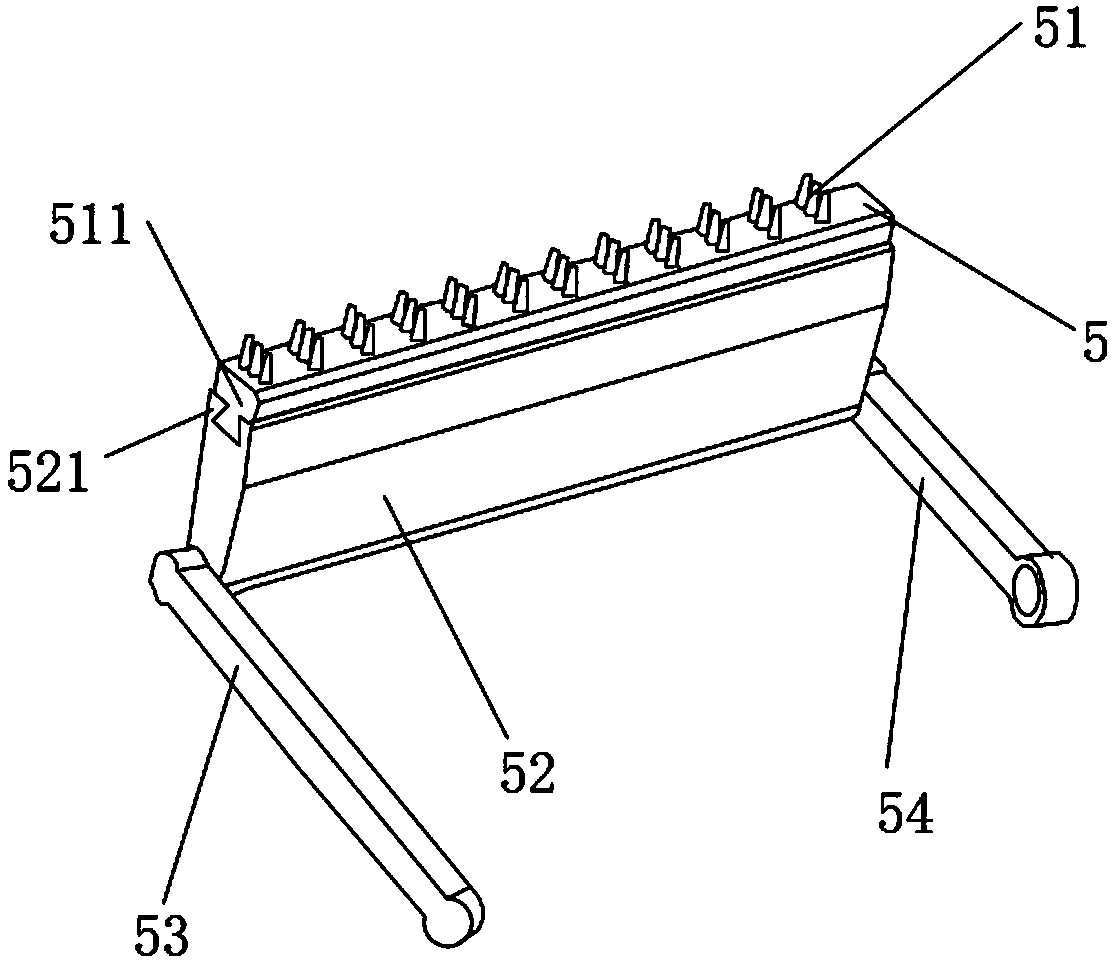

[0036] S2: Candied fruit pretreatment, using a punching machine to punch holes on the surface of the selected fruit, the holes are as deep as the seed core, and each fruit is punched with 10 to 15 holes;

[0037] S3: Freeze-drying, spread the perforated fruit on the freeze-drying mechanical storage tray, and dry until the water content of the fruit is 20%. The freeze-drying conditions are drying chamber pressure 110Pa, heating plate temperature -30°C, cooling rate - 0.3°C / min;

[0038]S4: Candied, adding the freeze-dried fruit to sugar water with a sugar content of 50%, and adding sodium citrate at a rate of 0.1% by weight of the fruit at the same time, stirring ...

Embodiment 2

[0051] A pollution-free and highly efficient processing technology for nuclei-containing candied fruit, using green plums as raw materials, specifically includes the following steps:

[0052] S1: Selection of raw materials, choose greengage fruit with large round fruit shape, small core, thin skin, and fresh color;

[0053] S2: Candied fruit pretreatment, using a punching machine to punch holes on the surface of the selected fruit, the holes are as deep as the seed core, and each fruit is punched with 10 to 15 holes;

[0054] S3: Freeze-drying, spread the perforated fruit on the freeze-drying mechanical storage tray, and dry until the water content of the fruit is 15%. The freeze-drying conditions are drying chamber pressure 100Pa, heating plate temperature -25°C, cooling rate 0.3°C / min;

[0055] S4: Candied, add the freeze-dried fruit into sugar water with a sugar content of 40%, and add sodium citrate with a fruit weight of 0.05% at the same time, stir well and cook for 8 h...

Embodiment 3

[0068] A pollution-free and highly efficient processing technology for nuclei-containing candied fruit, using green plums as raw materials, specifically includes the following steps:

[0069] S1: Selection of raw materials, choose greengage fruit with large round fruit shape, small core, thin skin, and fresh color;

[0070] S2: Candied fruit pretreatment, using a punching machine to punch holes on the surface of the selected fruit, the holes are as deep as the seed core, and each fruit is punched with 10 to 15 holes;

[0071] S3: Freeze-drying, spread the perforated fruit on the freeze-drying mechanical storage tray, and dry until the water content of the fruit is 18%. The freeze-drying conditions are drying chamber pressure 105Pa, heating plate temperature -27°C, cooling rate - 0.3°C / min;

[0072] S4: Candied, add the freeze-dried fruit to sugar water with a sugar content of 45%, and add sodium citrate at a weight of 0.07% of the fruit at the same time, stir evenly, cook for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com