High-performance copper azide composite initiating explosive and preparation method thereof

A technology of copper nitride and primary explosives, which is applied in the cross field of nanochemistry and energetic materials, can solve the problems of poor ignition ability and electrostatic sensitivity, achieve low electrostatic sensitivity, improve oxygen balance, and enhance ignition performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Synthesis of heteroatom-doped copper azide material (CA-HPCH)

[0024] The specific steps are:

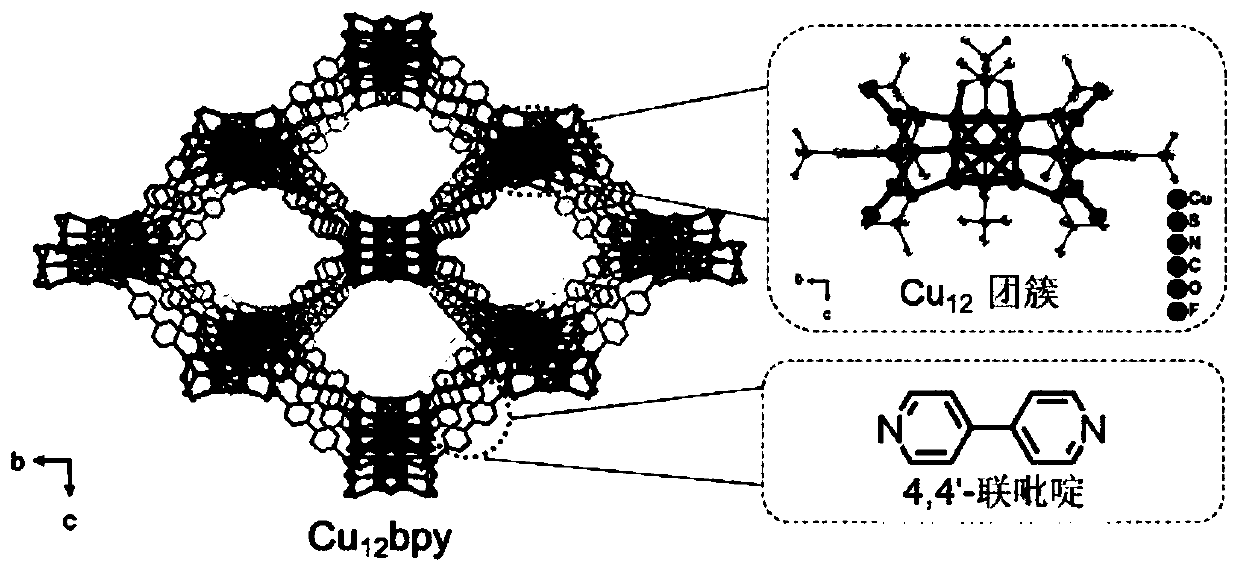

[0025] Step 1: 0.031g (0.2mmol) copper tert-butylsulfide ( t BuSCu) was placed in 3mL of chloroform, stirred rapidly; then added 0.03mL (0.4mmol) trifluoroacetic acid (CF 3 COOH), stirred until the solution was clear; added 0.02g (0.13mmol) 4,4'-bipyridyl (bpy) in 3mL methanol solution, and continued to stir for 5 minutes. After the reaction, the solution was slowly volatilized in the dark at room temperature, and orange cubic crystals were obtained after about 24 hours, which were recorded as copper-sulfur cluster-based assembly materials (Cu 12 bpy).

[0026] Step 2: the Cu obtained in the above steps 12 Fully grind bpy, spread it evenly in a high-temperature resistant quartz boat, place it in a tube furnace, and heat it at 5°C min -1 The temperature was raised to 400°C at a constant temperature for 1 hour under air atmosphere. After the tubular electric f...

Embodiment 2

[0032] Example 2: Performance test of copper azide-heteroatom co-doped porous carbon material (CA-HPCH) used as primer

[0033] Electrostatic sensitivity of CA-HPCH (E 50 ) Test: The electrostatic sensitivity of CA-HPCH was tested with an electrostatic spark sensitivity tester. Its calculation formula is E=0.5CU 2 , where C is the capacitance of the capacitor in Farads (F), and U is the charging voltage in Volts (V). E of CA-HPCH 50 The value is 1.1 mJ, much higher than that of pure CA powder (0.05 mJ), and comparable to the reported modified CA composites.

[0034] Flame Sensitivity of CA-HPCH (H 50 ) test: about 20mg of CA-HPCH was pressed onto the copper cap under a pressure of 39.2MPa, and ignited with black powder. h 50 Refers to the flame height from the black powder to the sample. H of CA-HPCH 50Value ≥ 60cm, reached the limit of detection conditions. This value is superior to CA (44 cm) and surpasses many previously reported primers, such as LS, graphene-modif...

Embodiment 3

[0035] Example 3: Performance test of a micro-initiator made of copper azide-heteroatom co-doped porous carbon material (CA-HPCH): The micro-initiator device includes a semiconductor bridge, a charging chamber and a photodiode. The current passed through the semiconductor bridge and increased to 2A at t = 2.5 μs, and the optical signal rose sharply at t = 7.0 μs, which indicated that the CA-HPCH ignited and exploded instantaneously. CA-HPCH corresponds to an input energy as low as 0.106mJ. This fast response time and low ignition energy demonstrate the excellent ignition performance of CA-HPCH in microinitiators.

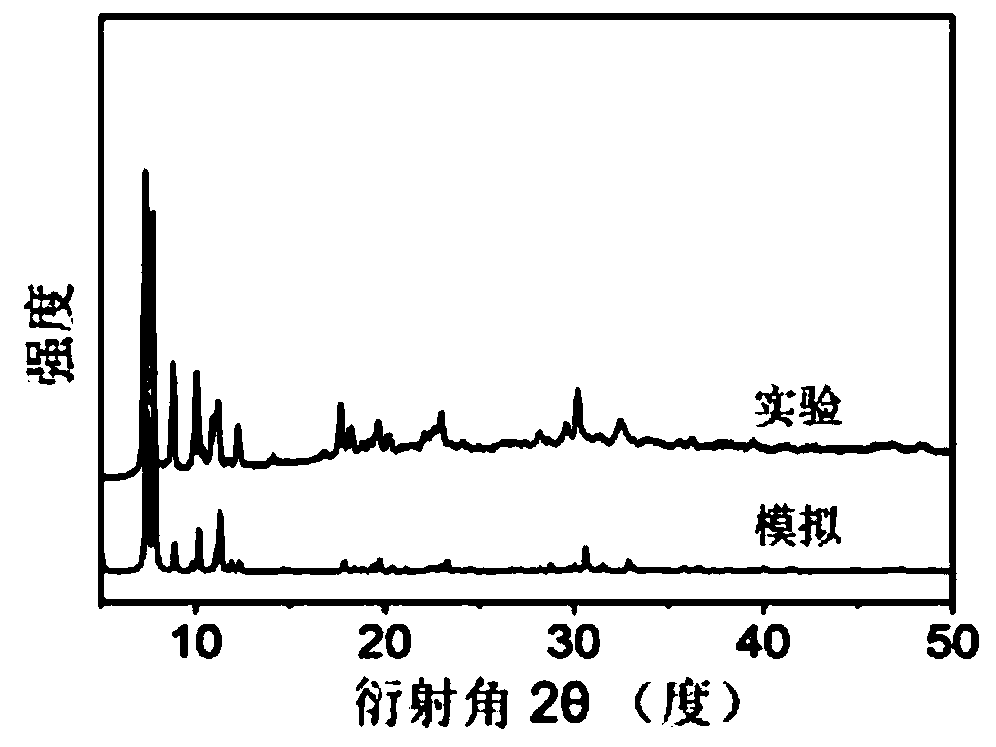

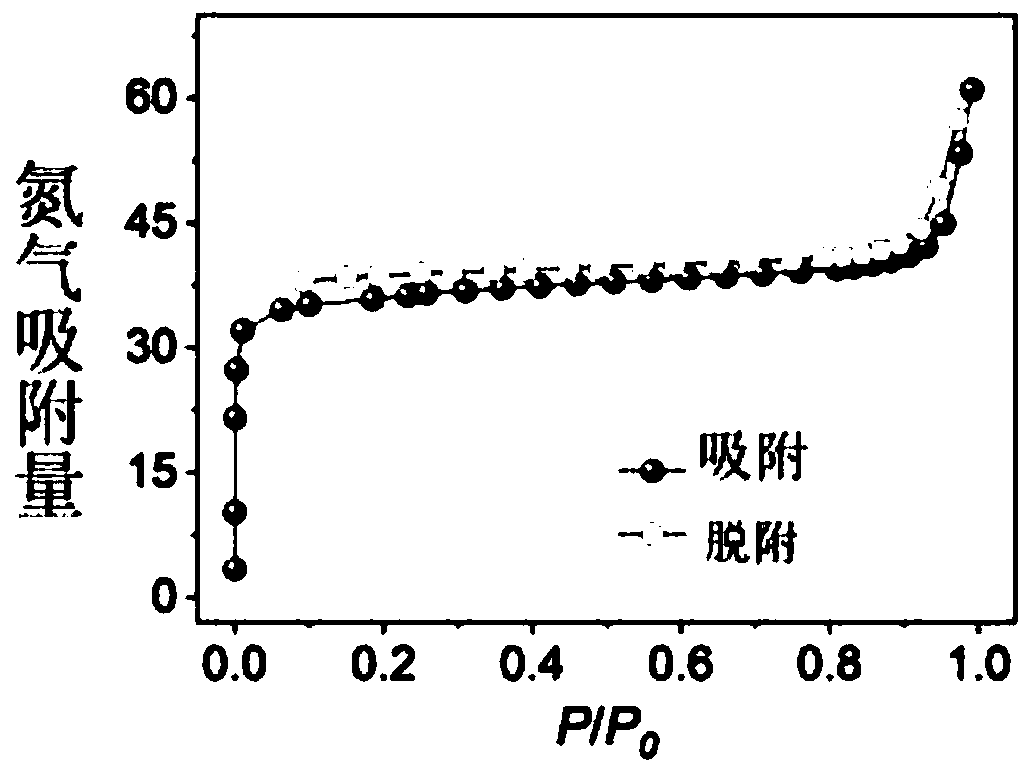

[0036] Get the copper-sulfur cluster-based assembly material (Cu 12 bpy) for further characterization, the process is as follows:

[0037] (1) Determination of crystal structure

[0038] The X-ray single crystal diffraction data of the polymer of the present invention is measured on a Rigaku XtaLAB Pro target single crystal instrument with a single crystal sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com