Method for separating and purifying cyclododecatriene

A cyclododecatriene, separation and purification technology, used in chemical instruments and methods, hydrocarbon purification/separation, hydrocarbons and other directions, can solve problems such as affecting the separation effect of equipment, increasing separation difficulty, and increasing separation difficulty. , to achieve the effect of reducing the continuous catalytic reaction, easy industrial scale-up, and easy separation operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

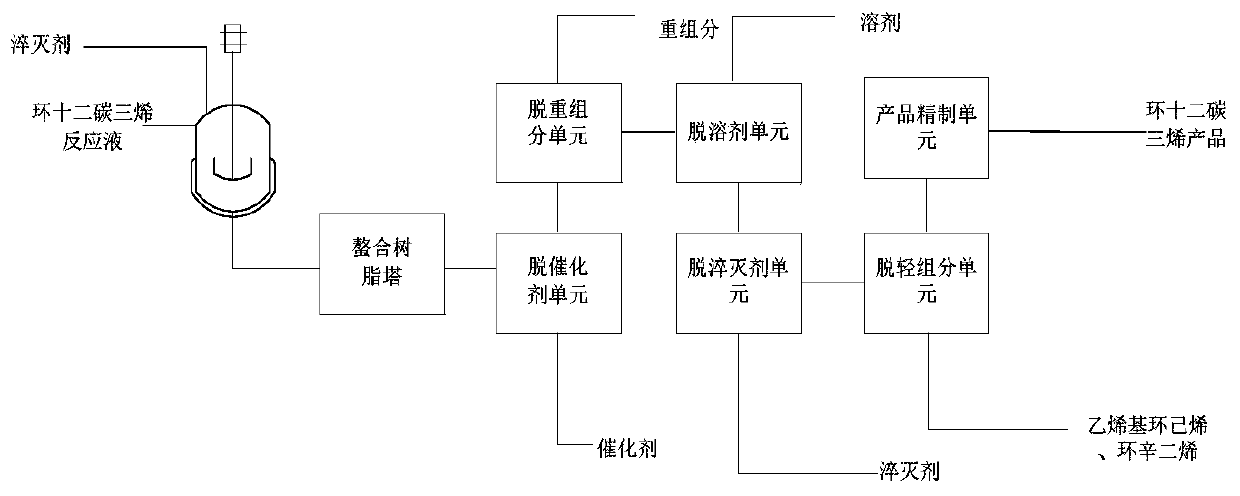

[0048] The process flow diagram of the separation and purification method of cyclododecatriene in this embodiment is as follows figure 1 As shown, the following steps are included: Cyclododecatriene reaction solution (the mass percentages of each component contained are as follows: 0.167% butadiene, 48.625% toluene, 0.865% VCH, 1.344% COD, ttt-CDT0.589 %, ttc-CDT 47.325%, heavy component 0.775%, Ziegler-Natta catalyst 0.22%) into the quenching kettle, the feed rate is 1200kg / h, and the mass fraction is 10% quenching agent IT-H The toluene solution enters the quenching tank and is fully mixed with the cyclododecatriene reaction solution, the feed rate is 78.3kg / h, and the Al in the quenching agent and Ziegler-Natta catalyst 3+ The mol ratio is 3:1, the quenching temperature is 75°C, the quenching pressure is 2KPa, and the quenching time is 60min to obtain the crude product of cyclododecatriene; the crude product of cyclododecatriene (containing Al 3+ 、Ti 4+ 、Ni 2+ Respective...

Embodiment 2

[0052] The process flow diagram of the separation and purification method of cyclododecatriene in this embodiment is as follows figure 1 As shown, the following steps are included: Cyclododecatriene reaction solution (the mass percentages of each component contained are as follows: 0.167% butadiene, 48.625% toluene, 0.865% VCH, 1.344% COD, 0.589% ttt-CDT , ttc-CDT 47.325%, heavy component 0.775%, Ziegler-Natta catalyst 0.22%) is sent into quenching kettle, and feed rate is 1200kg / h, and getting mass fraction is 8% of quenching agent IT-H The toluene solution enters the quenching tank and is fully mixed with cyclododecatriene, the feed rate is 81.51kg / h, the Al in the quenching agent and Ziegler-Natta catalyst 3+ Molar ratio is 2.5:1, quenching temperature 60 ℃, quenching pressure 25KPa, quenching time 45min, obtain cyclododecatriene crude product; Cyclododecatriene crude product (containing Al 3+ 、Ti 4+ 、Ni 2+ Respectively 500ppm, 35ppm, 25ppm) into the styrene-divinylbenze...

Embodiment 3

[0054] The difference between this example and Example 2 is that the quenching agent IT-H is replaced by IT-G, the feed rate is 123.6kg / h, and the composition of other raw materials and experimental conditions are the same as in Example 2. Get the product liquid of the cyclododecatriene product and analyze the product composition through gas chromatography. The analysis results are shown in Table 2.

[0055]Table 2 Analysis results of cyclododecatriene products of Examples 2-3

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com