Energy-saving production method of calcium lactate

A production method, calcium lactate technology, applied in chemical instruments and methods, carboxylate preparation, carboxylate preparation, etc., can solve the problems of high energy consumption in the drying process, large investment in calcium lactate production equipment, etc., and achieve low production cost , Omit the drying process and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

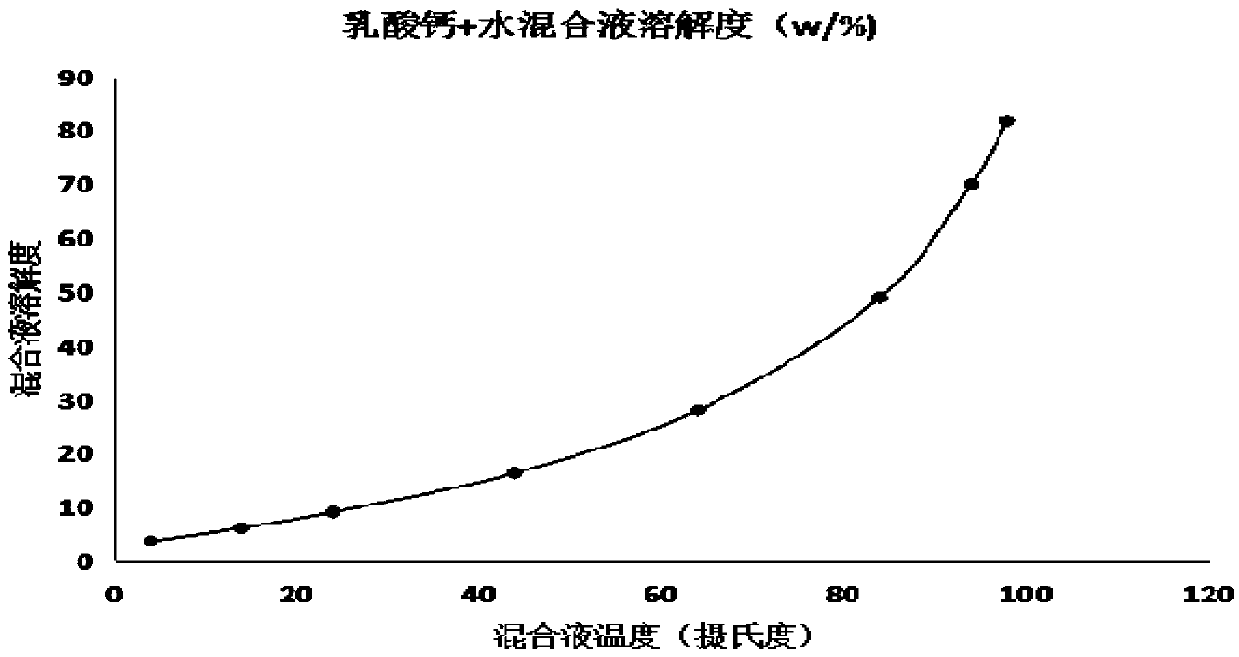

Method used

Image

Examples

Embodiment 1

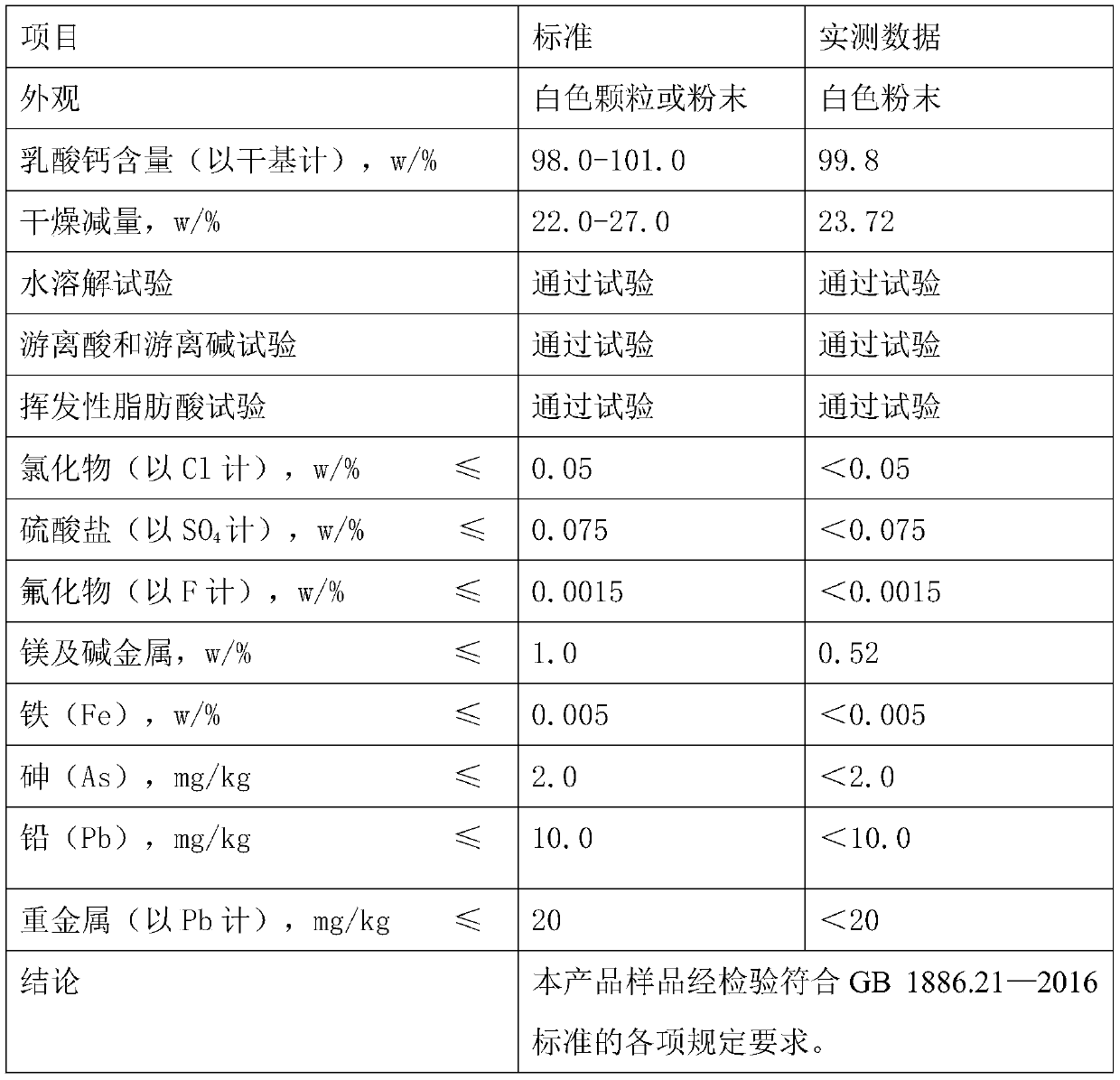

[0035] Take 675.6g (6mol) of food-grade lactic acid solution with a mass fraction of 80%, put it into a 2000ml conical flask, add 81.1g of pure water, and put it into a magnet. Place the triangular flask on a magnetic stirring heater and an electronic scale. After recording the quality parameters, under continuous stirring, heat the lactic acid solution to a slightly boiling state and maintain it. Continuously add a small amount of dried calcium oxide powder 168.32g (3mol ). During this period, the volatilized moisture is properly replenished according to the quality parameters. After 35 minutes, the addition reaction was completed, and the pH value of the reaction solution was measured to be 6.83. Pour the calcium lactate reaction solution into a 1000ml polyethylene plastic bottle under heat, seal it and cool it at room temperature for 10 hours, then disassemble the plastic bottle, break and mix the calcium lactate pentahydrate cylinder and test it. The dry weight of the pro...

Embodiment 2

[0039] Take 600kg of pharmaceutical-grade lactic acid solution with a mass fraction of 88%, put it into a 1000-liter reaction tank, add 139.29kg of pure water, and heat the lactic acid solution to a slight boiling state and maintain it through the jacket steam under continuous stirring. The calcium oxide powder 164.43kg after adding the drying. During this period, the volatilized water vapor is cooled by the condenser and flows back into the reaction tank. After 110 minutes, the addition of calcium oxide powder was completed, and the reaction was continued for 30 minutes, and the pH value of the reaction solution was measured to be 6.94. Put the calcium lactate reaction solution into a 50-liter dismantled stainless steel barrel one by one from the bottom valve under heat, seal it and cool it at room temperature in a clean area for 22 hours, then disassemble the stainless steel barrel, break and mix the calcium lactate pentahydrate cylinder According to the test, the content o...

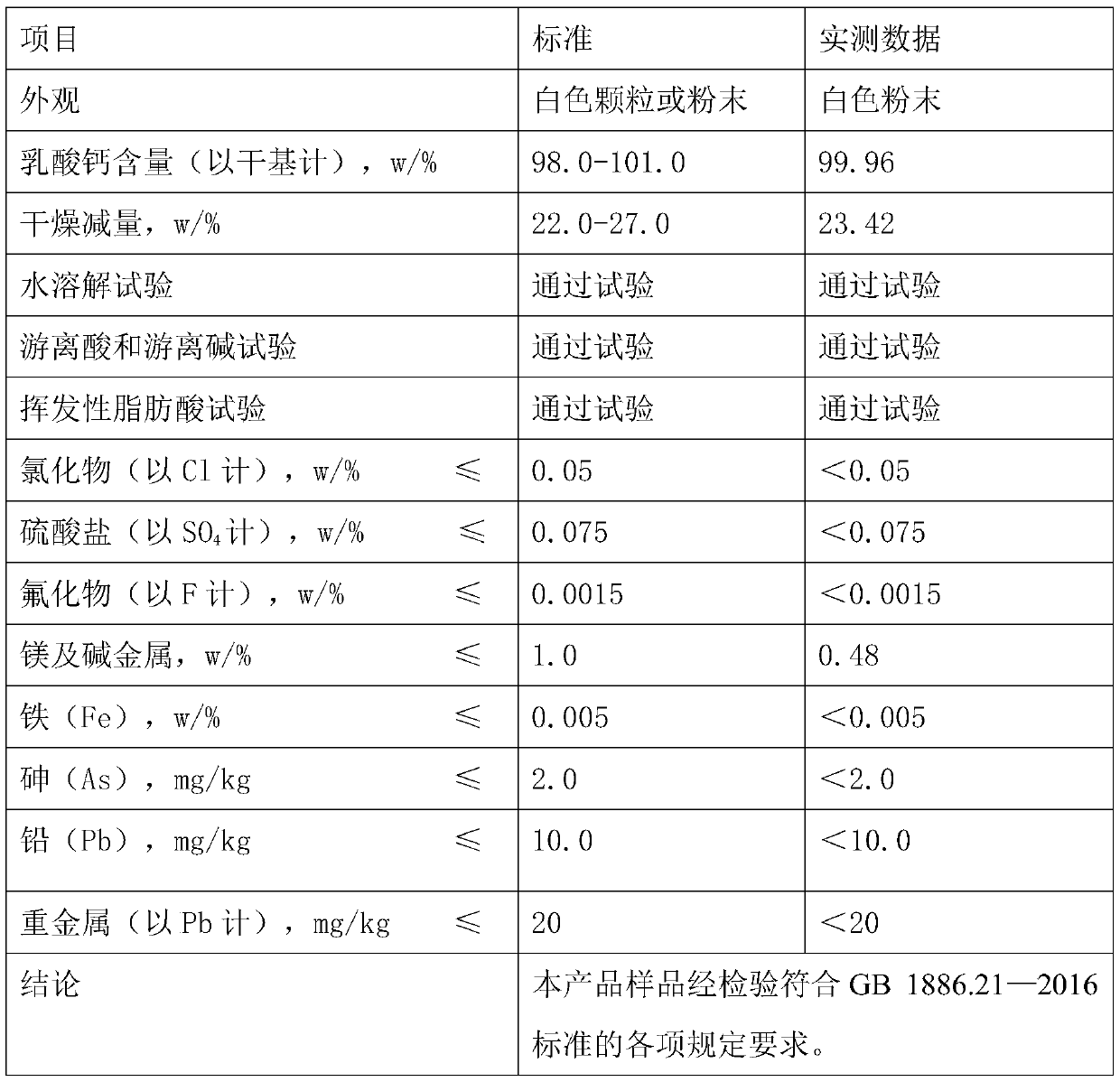

Embodiment 3

[0043]Take 600kg of food-grade lactic acid solution with a mass fraction of 80%, put it into a 1000-liter reaction tank, add 72kg of pure water, and heat the lactic acid solution to a slight boiling state and maintain it through jacket steam under continuous stirring. Add 150 kg of dried calcium oxide powder. During this period, the volatilized water vapor is cooled by the condenser and flows back into the reaction tank. After 115 minutes, the addition of calcium oxide powder was completed, and the reaction was continued for 30 minutes, and the pH value of the reaction solution was measured to be 7.05. Put the calcium lactate reaction solution into a 50-liter dismantled stainless steel barrel one by one from the bottom valve under heat, seal it and cool it at room temperature in a clean area for 24 hours, then disassemble the stainless steel barrel, break and mix the calcium lactate pentahydrate cylinder Detection, calcium lactate pentahydrate content 100.2%. Other physical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com