A kind of preparation method of metal lithium composite negative electrode for solid-state battery

A technology of solid-state batteries and metal lithium, which is applied in battery electrodes, electrode manufacturing, lithium batteries, etc., can solve the problems of unknown lithium metal negative electrodes, achieve uniform deposition and deintercalation, slow down volume changes, and good cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing a metal lithium composite negative electrode, comprising the following steps:

[0033] (1) Under the protection of inert gas, at a temperature of 200-400°C, mix and stir the filler powder and molten metal lithium until the powder material is completely dispersed in the molten metal lithium;

[0034] (2) While keeping the molten lithium metal, the above slurry is coated on the preheated metal foil substrate, cooled to room temperature naturally, and then cut into pieces.

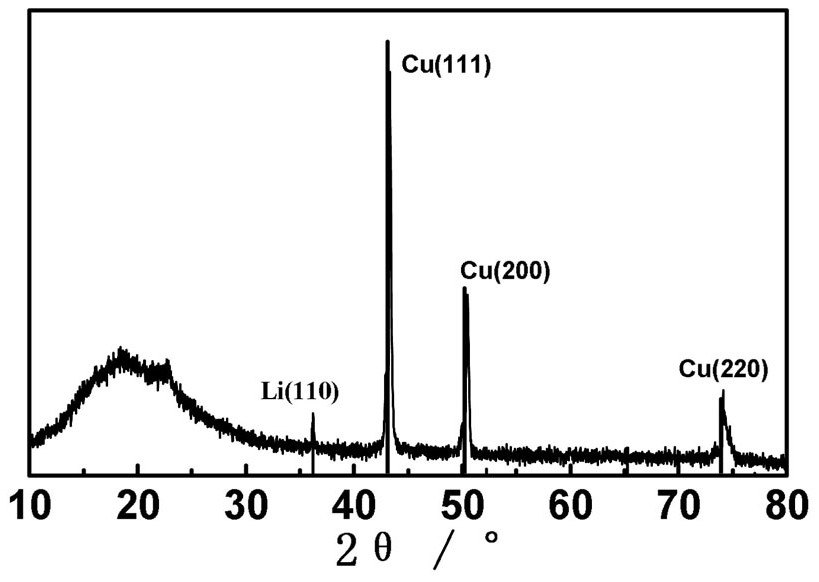

[0035] In the solution of the present invention, the filler powder is a material that does not react with lithium metal and has ionic conductivity or electronic conductivity, specifically including: copper powder, titanium powder, iron powder, nickel powder, carbon nanotubes, solid Electrolyte Li 7 La 3 Zr 2 o 12 , Li 3 One or more of N.

[0036] The mass ratio of filler powder to metal lithium is 1:5˜5:1.

[0037] In step (1), the stirring time is 0...

Embodiment 1

[0048] A preparation method of copper / lithium composite negative electrode of the present invention, comprises the following steps:

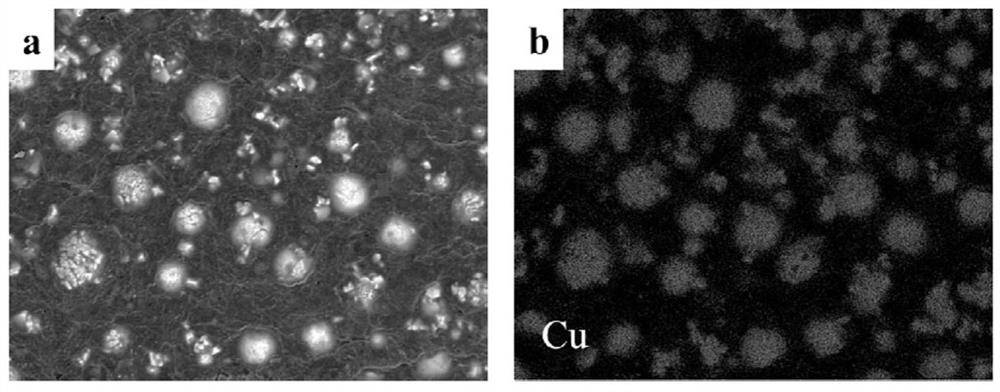

[0049] (1) In an inert gas protection, heat 0.23g metal lithium sheet to 300°C to melt, add 0.20g copper powder and mix with molten metal lithium, stir for 0.5h, so that copper powder is completely dispersed in molten metal lithium, and a mixed slurry is obtained material;

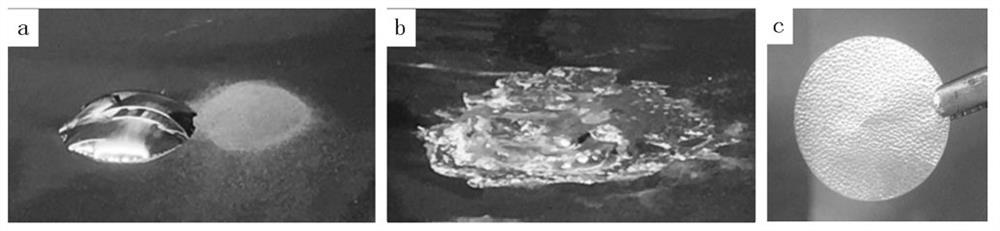

[0050] (2) Heat the stainless steel foil to 300°C and keep it warm. Preheat the scraper with a gap of 100 μm at 300°C for 15 minutes while keeping the lithium metal in a molten state, and then use the scraper to coat the copper-lithium mixed slurry on the stainless steel foil. cloth. After being naturally cooled to room temperature, it was cut into 16mm discs with a cutting machine.

Embodiment 2

[0052] A method for preparing a solid electrolyte / lithium composite negative electrode of the present invention, comprising the following steps:

[0053] (1) In an inert gas protection, heat 0.23g metal lithium sheet to 300°C to melt, add 0.20g lithium nitride powder and mix with molten metal lithium, stir for 1h, so that lithium nitride powder is completely dispersed in molten metal lithium, get mixed slurry;

[0054] (2) Heat the titanium foil to 300°C and keep it warm. Preheat the scraper with a gap of 100 μm at 300°C for 15 minutes while keeping the metal lithium molten, and then use the scraper to thermally coat the mixed slurry on the titanium foil. After being naturally cooled to room temperature, it was cut into 16mm discs with a cutting machine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com