Porous acid-base bifunctional solid catalyst as well as preparation method and application thereof

A technology of acid-base dual function and solid catalyst, which is applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc. high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

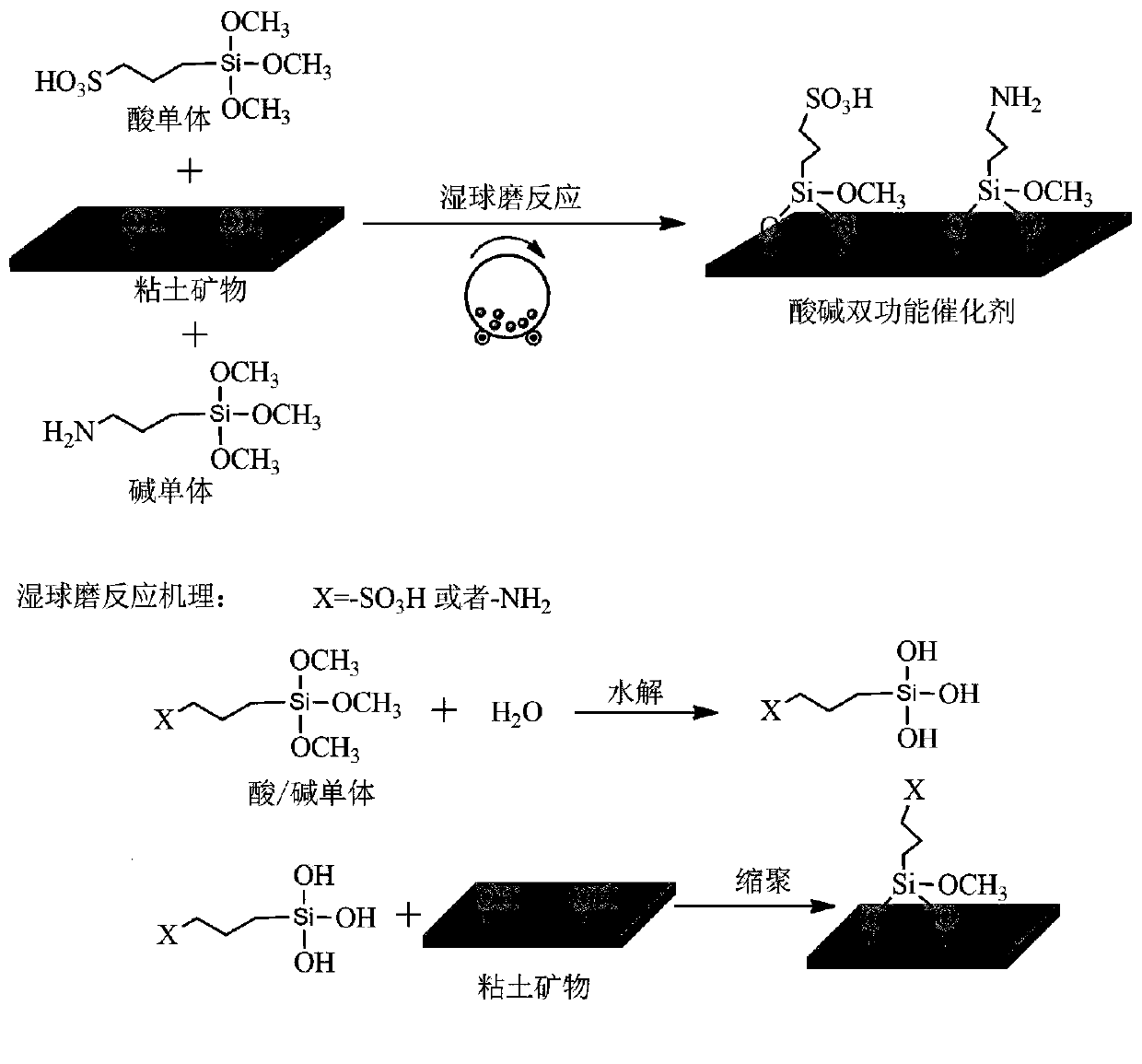

[0028] The invention provides a method for preparing a porous acid-base bifunctional solid catalyst, and the specific steps are:

[0029] Mixing clay minerals, acid monomers, alkali monomers and water to obtain a mixture;

[0030] Ball milling the mixture to obtain a porous acid-base bifunctional solid catalyst;

[0031] The acid monomer is chlorosulfonic acid and / or sulfonic acid triethoxysilane;

[0032] The basic monomer is 3-aminotriethoxysilane and / or 3-(2-aminoethyl)-aminopropyltrimethoxysilane.

[0033] The present invention has no special requirements on the sources of the clay minerals, acid monomers, alkali monomers and water, and commercially available products can be used.

[0034] In the present invention, clay minerals, acid monomers, alkali monomers and water are mixed to obtain a mixture.

[0035] In the present invention, the clay mineral preferably includes one or more of kaolinite, montmorillonite, palygorskite and sepiolite; when the clay mineral preferably includes tw...

Embodiment 1

[0056] Take 2g of kaolinite, 1g of chlorosulfonic acid, 1g of 3-aminotriethoxysilane, 10mL of deionized water, mix well, transfer to a 50mL ball milling tank, add 30g of zirconium dioxide ball milling beads with a diameter of 10mm, and perform mechanical The ball milling conditions are as follows: the speed is 250 rpm and the time is 60 min. After the ball milling is finished, wash with deionized water, the amount of deionized water is 20mL, magnetic stirring for 1h, suction filtration, repeat 3 times. Finally, it was dried at 65°C for 10 hours to obtain a porous acid-base bifunctional solid catalyst.

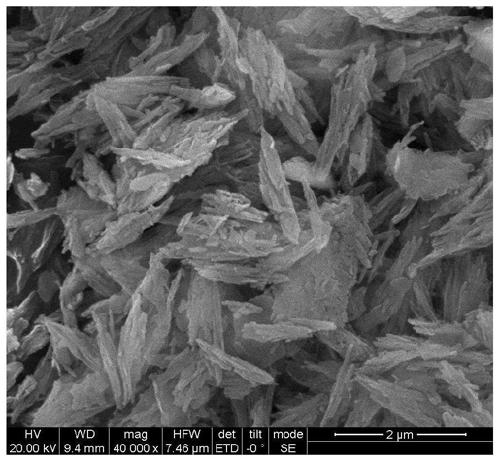

[0057] The scanning electron micrograph of the obtained porous acid-base bifunctional solid catalyst is as follows figure 2 Shown from figure 2 It can be concluded that the porous acid-base bifunctional solid catalyst prepared in this example has an irregular sheet structure.

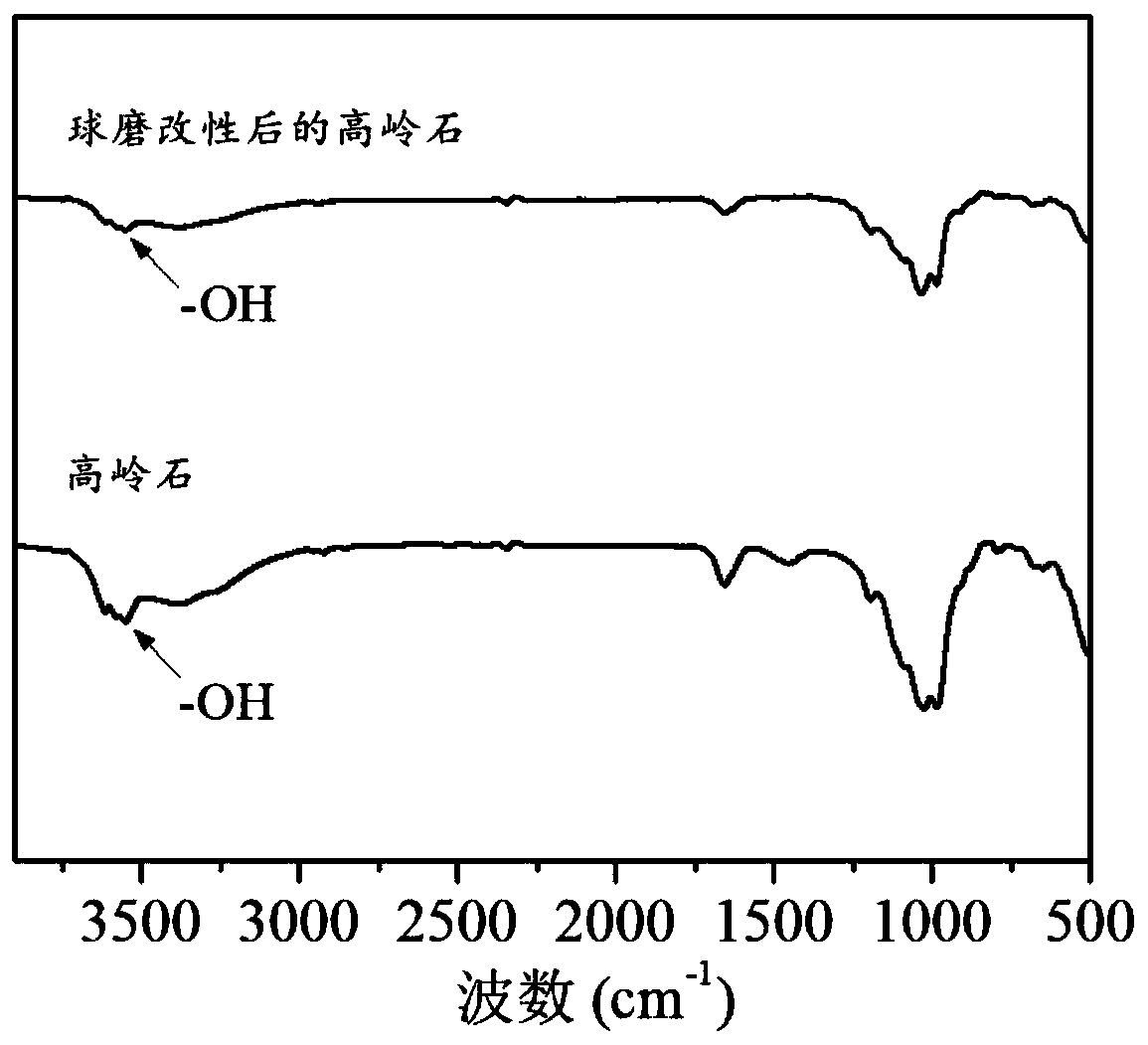

[0058] A Fourier transform infrared spectrometer (FT-IR) was used to analyze the structure of the solid...

Embodiment 2

[0061] Take 2g of palygorskite, 2g of chlorosulfonic acid, 1g of 3-aminotriethoxysilane, 10mL of deionized water, mix well, transfer to a 50mL ball milling tank, add 30g of zirconium dioxide ball milling beads with a diameter of 10mm, and perform mechanical The ball milling conditions are as follows: the speed is 300 rpm and the time is 120 min. After the ball milling is finished, wash with deionized water, the amount of deionized water is 20mL, magnetic stirring for 1h, suction filtration, repeat 3 times. Finally, it was dried at 65°C for 12 hours to obtain a porous acid-base bifunctional solid catalyst.

[0062] Using test equipment (nitrogen adsorption and desorption instrument, NH 3 -TPD and CO 2 -TPD) Test the porous structure, acidity and alkalinity of the solid catalyst prepared in Example 2, and it can be concluded that the total specific surface area of the porous acid-base bifunctional solid catalyst prepared in this embodiment is 318.4m 2 / g, the mesoporous specific ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com