Method for preparing acid liquid system

An acid solution and system technology, applied in chemical instruments and methods, drilling composition, etc., can solve the difficulty of breaking the gel, high reservoir damage, unable to meet the acid fracturing or acidification requirements of tight porous carbonate rocks, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

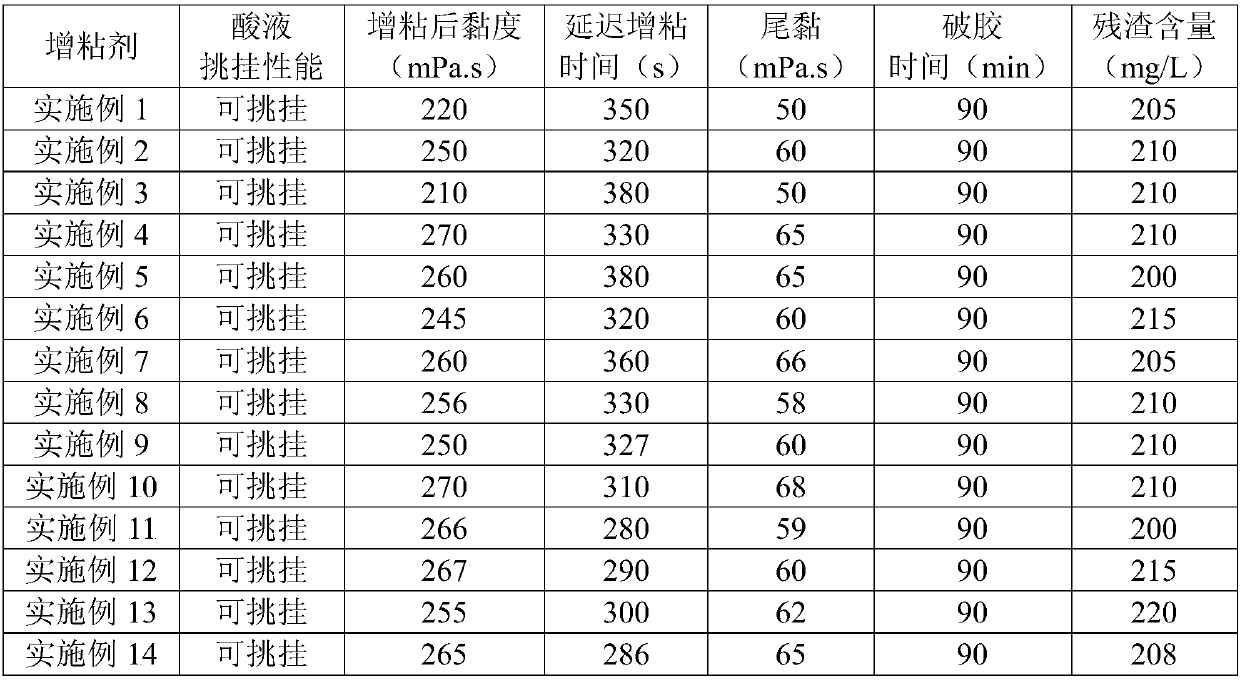

Examples

preparation example Construction

[0065] Preparation of thickener for clean self-assembled acids:

[0066] Thickener for clean self-assembled acid 1

[0067] 1) Prepare an aqueous solution of polymerized monomers, in parts by mass, chlorinate 35 parts of acrylamide, 64 parts of 2-acrylamide-2-methylpropanesulfonic acid (AMPS), and 0.8 parts of hexadecyldimethylallyl Ammonium is added in the beaker, and distilled water is added to dissolve, so that the total mass content of the three types of monomers is 25wt%;

[0068] 2) Add 1.0wt% urea, 0.05wt% sodium formate, 0.03wt% tetrasodium edetate, 0.05wt% ethylenediamine to the above-mentioned monomer aqueous solution (based on the total mass of the three monomers as 100%) , stir and dissolve evenly, put it in a 5°C water bath and cool for 30 minutes, and cool the temperature to 5°C;

[0069] 3) Add a certain amount of sodium hydroxide to the above solution to adjust the pH value to 6.5, continue cooling in a 5°C water bath for 30 minutes, cool the temperature to 5...

Embodiment 1

[0216] 1) Prepare the self-assembly cleaning acid base liquid according to the following components by mass: Take 100 parts of hydrochloric acid solution with a concentration of 15wt%, slowly add 0.5 parts of thickener 1 for self-assembly cleaning acid at a speed of 500r / min, continue Stir at 500r / min rotating speed for half an hour to form a uniform solution, then add 0.6 parts of iron ion stabilizer citric acid (commercially available), 1.0 part of 2-methylquinoline benzyl quaternary ammonium salt corrosion inhibitor (commercially available) and 0.6 parts of demulsification and drainage aid 1, stirred evenly under 500r / min rotating speed, sealed at room temperature and stood still for 3 hours;

[0217]2) Add 1 part of the self-assembling cleaning acid tackifier 1 to the above-mentioned self-assembling cleaning acid base solution, and stir at 500 r / min for 8 minutes to form the self-assembling cleaning acid.

Embodiment 2

[0219] 1) Prepare self-assembled cleaning acid base solution according to the following components by mass: Take 100 parts of hydrochloric acid solution with a concentration of 20 wt%, and slowly add 0.8 parts of thickener 2 for self-assembled cleaning acid at a speed of 500r / min, Continue stirring at 600r / min for half an hour to form a uniform solution, then add 1.0 parts of iron ion stabilizer lactic acid (commercially available), 2.5 parts of 1-aminoethyl-2-pentadecylimidazoline Quaternary ammonium salt (commercially available) and 0.8 parts of demulsification and drainage aid 3 are stirred evenly at a speed of 550r / min, sealed and placed at room temperature for 5 hours;

[0220] 2) Add 1.5 parts of the self-assembling cleaning acid tackifier 2 to the above-mentioned self-assembling cleaning acid base solution, and stir for 8 minutes at a speed of 1000 r / min to form the self-assembling cleaning acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com