TEMPO oxidized cellulose/PEDOT polymer as well as preparation method and application thereof

A technology for oxidizing cellulose and polymers, which is applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc. It can solve problems such as difficult to determine, limit applications, and complex lignin structure, so as to achieve abundant resources, reduce consumption, and solve The effect of device inefficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

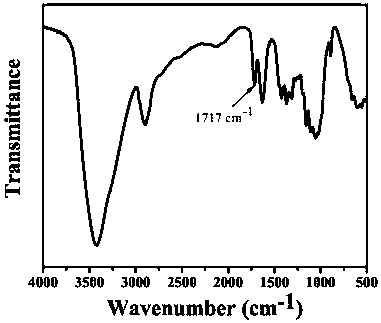

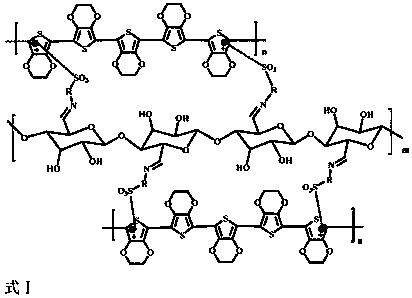

[0067] In the present embodiment, the structural formula of formula III TEMPO oxidized cellulose / PEDOT polymer is:

[0068]

[0069] The preparation method of above-mentioned formula III TEMPO oxidized cellulose / PEDOT polymer comprises the steps:

[0070] Step 1: Synthesis of intermediate 6-formyl cellulose

[0071] Measure 100mL of 1% dissociated fiber slurry in a 250mL three-necked flask, add 0.1 part of sodium bromide and a certain amount of TEMPO reagent, stir the reaction on a magnetic stirrer, then add a certain volume of NaClO solution, and then use 0.1 part of TEMPO reagent HCl adjusts the reaction pH value of the system. During the reaction, continuously add 0.1 parts of NaOH solution dropwise to maintain the pH value of the system until the NaOH solution is no longer consumed. After the reaction is completed, filter the membrane in a sand core crucible and wash it with water for several times. A sample of IV'a was obtained in 93% yield. GPC test molecular weight...

Embodiment 2

[0079] In the present embodiment, the structural formula of formula VI TEMPO oxidized cellulose / PEDOT polymer is:

[0080]

[0081] The preparation method of above-mentioned formula VI TEMPO oxidized cellulose / PEDOT polymer comprises the steps:

[0082] Step 1: Synthesis of intermediates

[0083] Put 2 parts of the formula 6-formyl cellulose compound in a three-neck flask with a capacity of 250ml, protect it with argon, add a mixed solution of 80ml of methanol and 4mL of acetic acid, stir for 45 minutes, and inject 2 parts of p-aminobiphenylsulfonic acid The reaction system was heated to 60° C. under stirring, and reacted for 4 days. After the reaction, it was dialyzed with 500, 1000, and 1500 mesh filter membranes respectively, and freeze-dried to obtain the compound of formula V with a yield of 92%. Structure detection: 1 H NMR (D 2 O): δ (ppm) = 8.83 (s, 1H), 8.58 (s, 1H), 8.32 (d, J = 8.48Hz, 2H), 8.06 (d, J = 8.48Hz, 2H), 7.86d, J =8.48Hz, 2H), 7.69(d, J=8.48Hz, ...

Embodiment 3

[0088] Fabrication of organic solar cells with anode interface layer based on TEMPO oxidized cellulose / PEDOT polymer

[0089] The above functionalized TEMPO oxidized cellulose / PEDOT can be used as an anode interface material in organic solar cells.

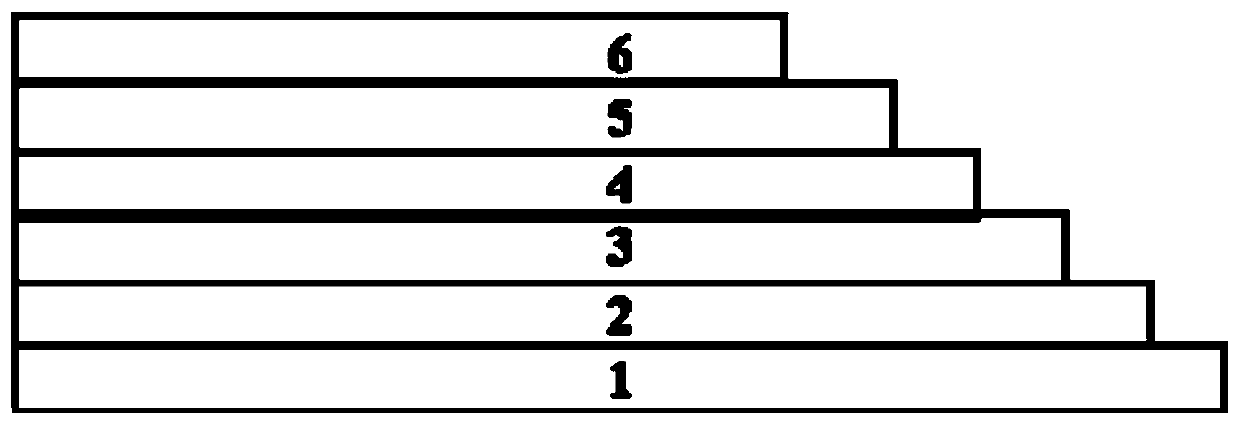

[0090] The organic solar cell has a layered structure, such as figure 2 As shown, from the substrate to the electrode, the substrate 1, the transparent conductive film 2, the anode interface layer 3, the active layer 4, the cathode interface layer 5, and the electrode 6 are sequentially included.

[0091] The substrates are glass and / or flexible transparent films.

[0092] The material of the transparent conductive film is indium-doped tin oxide, silver nanowire; and / or.

[0093] The electrode material is metal aluminum, silver; and / or.

[0094] The device also includes one or more of the following features:

[0095] The thickness of the anode interface layer (4) is 30-50nm; and / or;

[0096] The active layer (5) has a thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com