A kind of ceramic ablation-resistant coating and preparation method thereof

A kind of ablation resistance and coating technology, applied in coatings, fire retardant coatings, etc., can solve the problems of easy cracking of coatings, poor ablation resistance, poor thermal conductivity, etc. Corrosion performance and heat resistance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

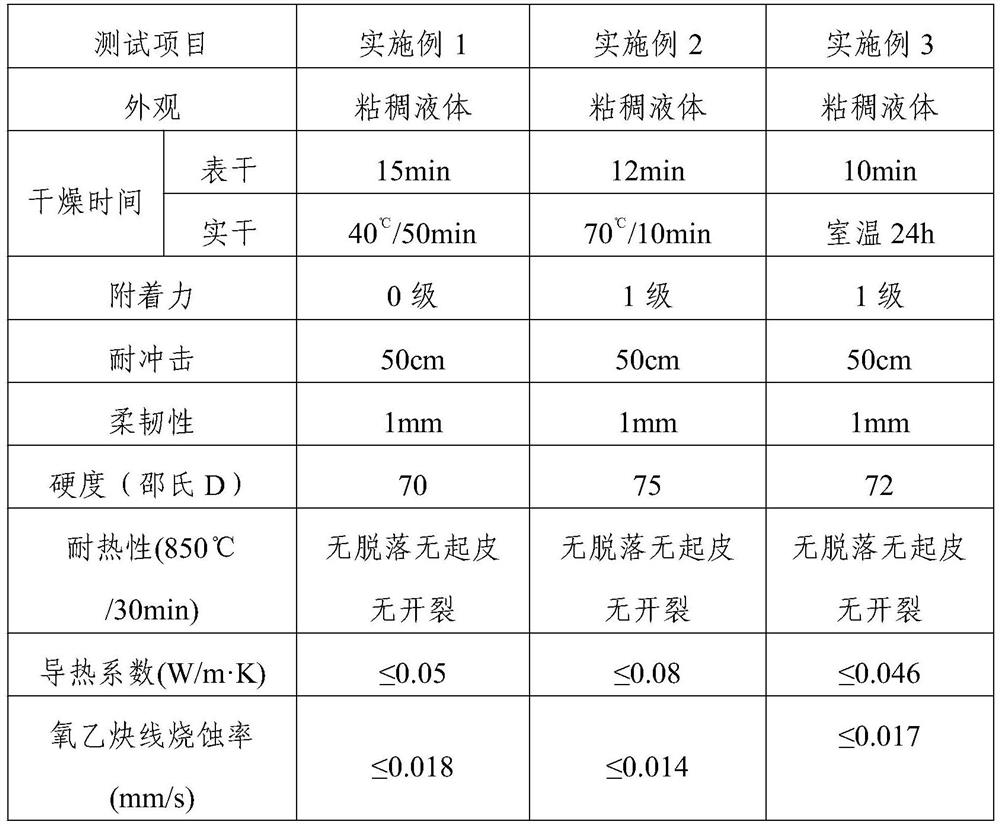

Examples

preparation example Construction

[0036] The preparation method of this coating specifically comprises the following steps:

[0037] (1) Preparation of silicone resin by sol-gel method

[0038] Add the measured alkoxysilane, (aryl) boric acid compound and absolute ethanol into the reaction kettle equipped with a reflux condenser, a magnetic stirring paddle, a thermometer, a thermocouple and a constant pressure dropping funnel, and first raise the temperature to 50-70 ℃, after the (aryl) boronic acid compound is completely dissolved, add an appropriate amount of deionized water and catalyst to the constant pressure dropping funnel, and drop it within 1.5~3h; continue to heat up to 75~120℃, and react for 3~ After 6 hours, distill under reduced pressure, transfer it to a vacuum oven, and keep it at 100-120° C. for 2-4 hours to obtain a silicone prepolymer. Wherein, the molar ratio of alkoxysilane to (aryl)boronic acid compound is 1:0.8-2.5. Next, epoxy resin is used to modify the silicone prepolymer, and the ac...

Embodiment 1

[0051] This embodiment proposes a porcelain ablation-resistant coating, including the following components and mass percentages: 50% to 65% of a silicone resin, 8% to 15% of a curing agent, 25% to 35% of a filler, and 0.1% of an auxiliary agent % to 0.5%.

[0052] The preparation method of this coating comprises the following steps:

[0053] (1) Add metered diphenyldiethoxysilane, 4-(1-naphthyl)phenylboronic acid, absolute ethanol and hydrochloric acid into the In the reaction kettle of the liquid funnel, first raise the temperature to 60°C, and after the 4-(1-naphthyl)phenylboronic acid is completely dissolved, add an appropriate amount of deionized water and catalyst to the constant pressure dropping funnel, and drop it within 1.5h. Addition is complete; continue to heat up to 120°C, react for 4 hours, distill under reduced pressure, transfer it to a vacuum oven and keep it at 100°C for 4 hours to obtain a silicone prepolymer. Wherein, the molar ratio of diphenyldiethoxysi...

Embodiment 2

[0057] This embodiment proposes a porcelain ablation-resistant coating, which includes the following components and mass percentages: 55% to 65% of a silicone resin, 8% to 15% of a curing agent, 20% to 35% of a filler, and 0.1% of an auxiliary agent % to 0.5%.

[0058] The preparation method of this coating comprises the following steps:

[0059] (1) Add the metered mixture of phenyltriethoxysilane, phenylboronic acid and hydroxymethylphenylboronic acid, absolute ethanol and acetic acid into a device equipped with a reflux condenser, a magnetic stirring paddle, a thermometer, a thermocouple and a constant pressure drop In the reaction kettle of the liquid funnel, first raise the temperature to 65 ° C, after the mixture of phenylboronic acid and hydroxymethylphenylboronic acid is completely dissolved, add an appropriate amount of deionized water and acetic acid to the constant pressure dropping funnel, and drop it within 2 hours Addition is complete; continue to heat up to 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com