Flexible ZnO@TiN core-shell structure array cathode and preparation method thereof

A core-shell structure and array technology, applied in the field of cold cathode electron emission materials, can solve the problems of low work function electron transport performance, poor electron transport and thermal conductivity, and small saturated emission current density, to achieve electron transport and conduction Excellent ability, excellent core-shell bonding strength, and high emission current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

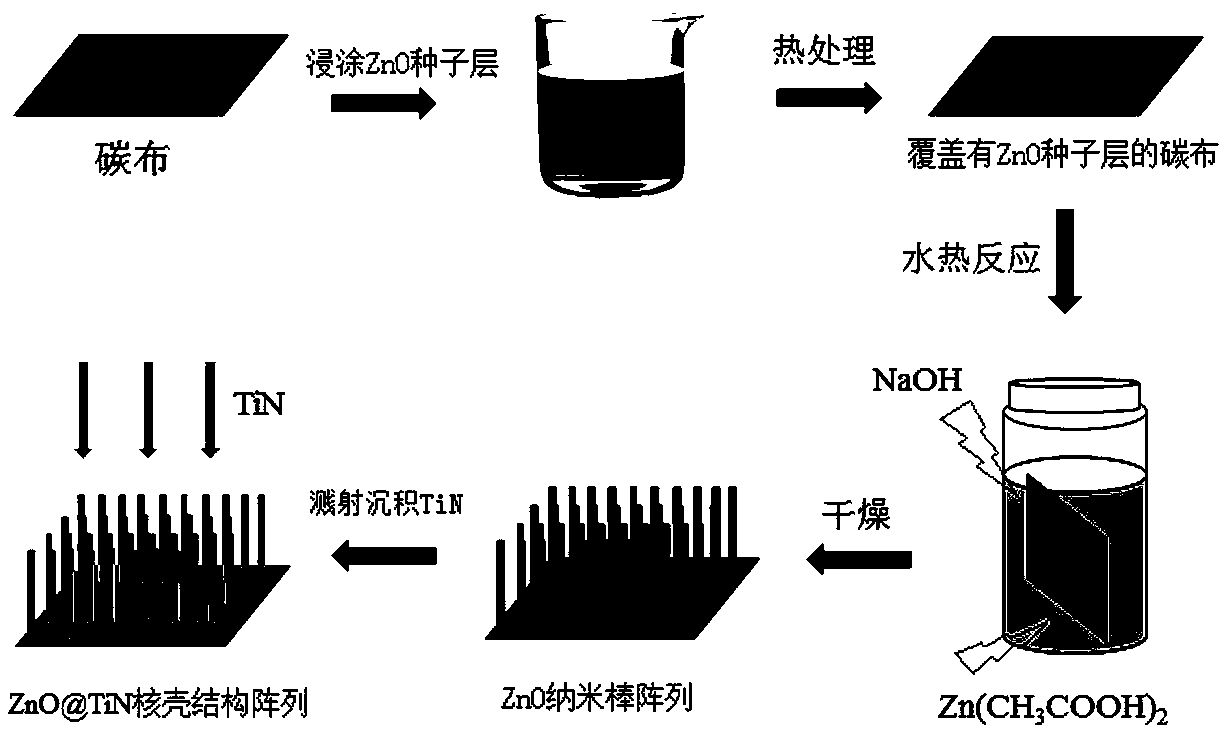

[0035] The present invention also provides a preparation method of the flexible ZnO@TiN core-shell structure array cathode, such as figure 1 shown, including the following steps:

[0036] (1) The ZnO seed layer was prepared on both sides of the carbon cloth by the sol-gel method. Specifically include the following steps:

[0037] (101) 1.4~2.8 g of Zn(CH 3 COOH) 2 Dissolve in 35-80 mL of absolute ethanol, stir at room temperature for 20-40 min, then slowly drop into 0.8-1.5 mL of ethanolamine; put the obtained solution in a dry box, and age at 50-80 ℃ for 6-14 h to form Sol;

[0038] (102) After soaking the carbon cloth in the sol for 8-20 s, take it out, put the dip-coated carbon cloth in a drying oven at 70-90°C for heat treatment for 10-20 min;

[0039] (103) After repeating step (102) several times, put the gel-coated carbon cloth into a muffle furnace for annealing to 400-480 °C, and keep it warm for 40-70 min to prepare ZnO seeds on both sides of the carbon cloth ...

Embodiment 1

[0050] (1) Preparation of ZnO seed layer by sol-gel method

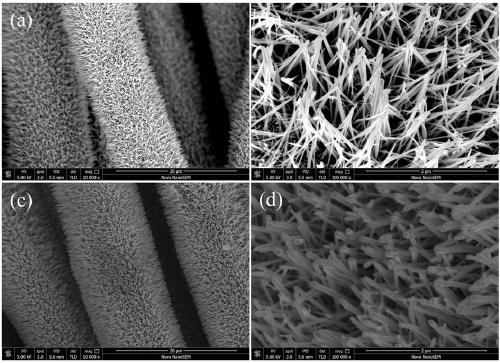

[0051] 2.6 g of Zn(CH 3 COOH) 2 Dissolve in 80 mL of ethanol, stir at room temperature for 30 min, then slowly drop into 1.4 mL of ethanolamine, then put the resulting solution in a dry box, and age at 70 °C for 14 h to form a sol. Then, the carbon cloth (3 cm × 6 cm) was dipped in the above sol for 15 s and then taken out, and the dipped carbon fiber cloth was heat-treated in a drying oven at 80 °C for 20 min. After repeating the above process four times, the gel-coated carbon cloth was annealed in a muffle furnace to 480 °C for 50 min.

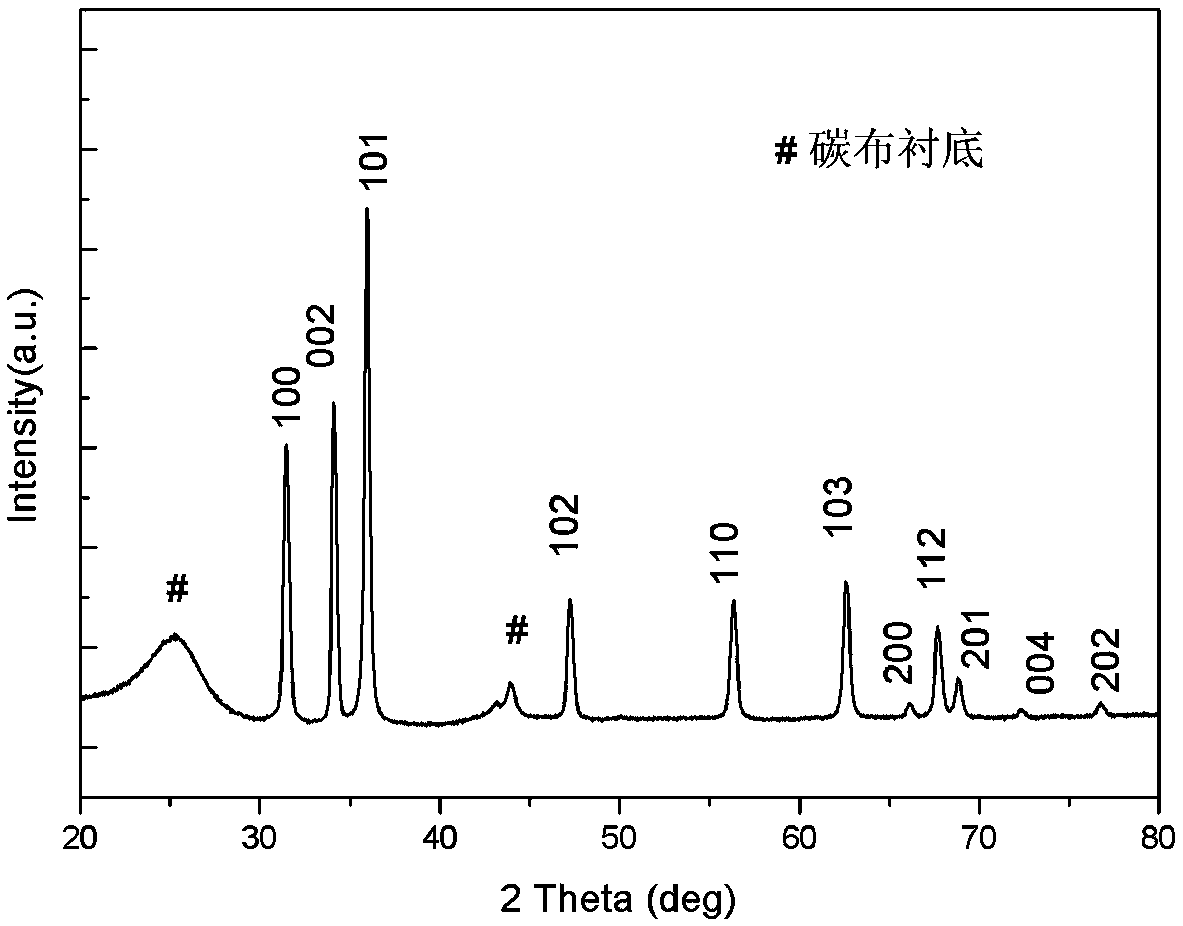

[0052] (2) Preparation of ZnO nanorod arrays by liquid phase method

[0053] 1.3 g of Zn(CH 3 COOH) 2 Add to 45 ml of deionized water, stir well to form Zn(CH 3 COOH) 2 solution, 5.1 g of NaOH was added to 35 mL of deionized water, and fully stirred to form a NaOH solution. The carbon cloth coated with the seed layer in step (1) was then vertically inserted into the Zn(CH ...

Embodiment 2

[0057] (1) Preparation of ZnO seed layer by sol-gel method

[0058] 2.2 g of Zn(CH 3 COOH) 2 Dissolve in 50 mL of ethanol, stir at room temperature for 30 min, then slowly drop into 1.2 mL of ethanolamine, then put the resulting solution in a dry box, and age at 60 °C for 8 h to form a sol. Then, the carbon cloth (3 cm × 6 cm) was dipped in the above sol for 10 s and then taken out, and the dipped carbon fiber cloth was heat-treated in a drying oven at 90 °C for 10 min. After repeating the above process four times, the gel-coated carbon cloth was annealed in a muffle furnace to 450 °C for 60 min.

[0059] (2) Preparation of ZnO nanorod arrays by liquid phase method

[0060] 1.2 g of Zn(CH 3 COOH) 2 Add to 40 ml of deionized water, stir well to form Zn(CH 3 COOH) 2 solution, add 4.6 g of NaOH to 30 mL of deionized water, stir well to form a NaOH solution; then insert the carbon cloth coated with the seed layer in step (1) vertically into the Zn(CH 3 COOH) 2 In a reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com