Composite material and sheet for microwave circuit base plate, and microwave circuit base plate and preparation method thereof

A circuit substrate and composite material technology, which is applied in the field of printed circuit substrate and its manufacturing, can solve the problems of limited use value, low strength of turning materials, and easy cracks, etc., and achieve increased strength, low porosity, and stable dielectric properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

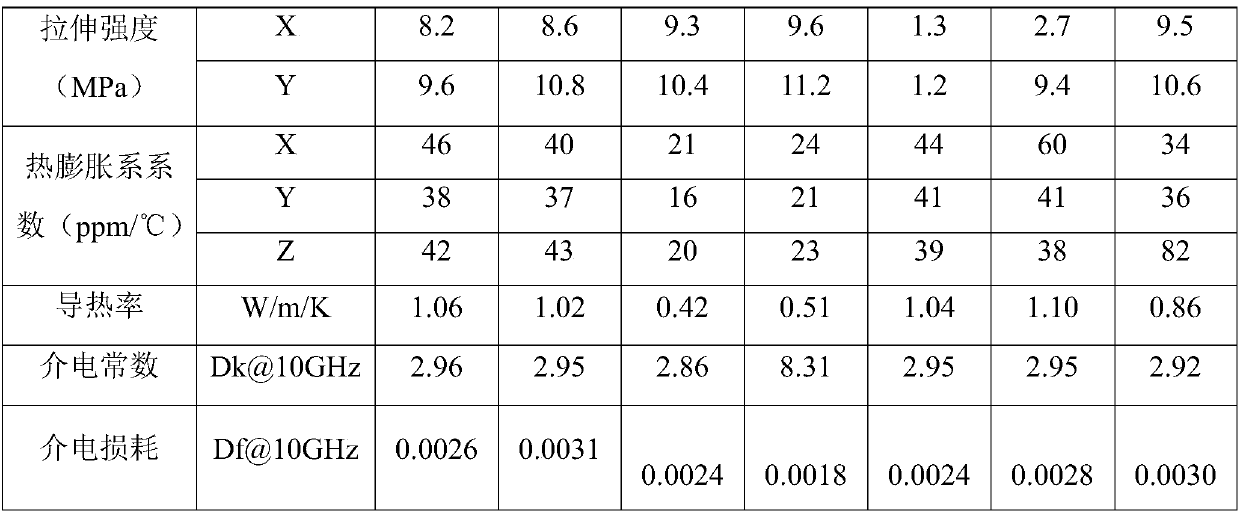

Examples

Embodiment 1

[0035] Weigh 15kg of PTFE emulsion (Daikin D210, PTFE solid content 60%), add water to dilute to 40wt% concentration, hexagonal boron nitride (D50=15 micron, flake, Suzhou Napo Material Technology Co., Ltd.) 6kg, coupling agent CG-P13 30g, use a mixer to mix for 1h at a speed of 600rpm to get a uniformly mixed glue.

[0036] Slowly add ethanol to the above glue solution until a muddy solid precipitate appears, centrifuge to remove the supernatant, and dry the remaining slurry mixture at 120° C. to obtain a slightly agglomerated solid.

[0037] The obtained solid powder was crushed through a 40-mesh sieve, and then No. 200 solvent oil was added according to a mass ratio of 10 wt%, mixed evenly and aged for 5 hours.

[0038] Add the cured powder into a low-speed mixer and stir for 30 minutes, and it is observed that the powder is fibrous.

[0039] The fibrous powder was treated in an oven at 300°C for 5 hours to remove lubricants and additives in the emulsion.

[0040] The abo...

Embodiment 2

[0045] Weigh 15kg of PTFE emulsion (Daikin D210, PTFE solid content 60%), add water to dilute to 40wt% concentration, hexagonal boron nitride (D50=15 micron, flake, Suzhou Napo Material Technology Co., Ltd.) 6kg, coupling agent Z-6132 30g, glass fiber powder 1kg (giant stone EMG13-250, 13 microns in diameter, 50 microns in length), rotating speed 600rpm, to obtain a uniformly mixed glue.

[0046] Slowly add ethanol to the above glue solution until a muddy solid precipitate appears, centrifuge to remove the supernatant, and dry the remaining slurry mixture at 120° C. to obtain a slightly agglomerated solid.

[0047] The obtained solid powder was crushed through a 40-mesh sieve, and then No. 200 solvent oil was added according to a mass ratio of 10 wt%, mixed evenly and aged for 5 hours.

[0048] Add the cured powder into a low-speed mixer and stir for 30 minutes, and it is observed that the powder is fibrous.

[0049] The fibrous powder was treated in an oven at 300°C for 5 ho...

Embodiment 3

[0055] Take by weighing PTFE emulsion 12.5kg (Daikin D210, PTFE solid content 60%), add water and dilute to 40wt% concentration, silicon micropowder (D50=20 μ m, Lianyungang Warwick Silicon Micropowder Co., Ltd.) 7.5kg, coupling agent KH-1621 40g, Use a mixer to mix for 1 hour at a speed of 600 rpm to obtain a uniformly mixed glue solution.

[0056] Slowly add ethanol to the above glue until a muddy solid precipitate appears, centrifuge to remove the supernatant, and dry the remaining slurry mixture at 120°C to obtain a slightly agglomerated solid;

[0057] Break the obtained solid powder through a 40-mesh sieve, then add No. 200 solvent oil according to the mass ratio of 10wt%, mix evenly, and mature for 5 hours;

[0058] Add the cured powder into a low-speed mixer and stir for 30 minutes, and it is observed that the powder is fibrous;

[0059] Treat the fibrous powder in an oven at 300°C for 5 hours to remove lubricants and additives in the emulsion;

[0060] The above pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com