Preparation and application of graphene composite fiber nonwoven fabric for catalytically degrading neuropathic chemical warfare agents

A graphene fiber and graphene composite technology, applied in the field of chemical defense, can solve the problem of low utilization of MOFs catalysts, and achieve the effect of improving catalytic degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

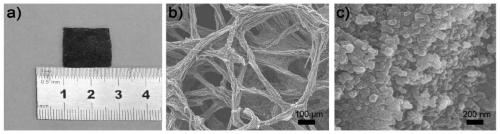

[0040] (1) Preparation of graphene fiber non-woven fabric: the graphene oxide aqueous dispersion with a concentration of 5mg / mL is the spinning stock solution, and the KOH solution of 5wt% is the coagulation bath, and continuous wet spinning is carried out to obtain graphene oxide The fibers were left to stand at room temperature for 8 hours, and then vacuum-dried at 60°C for 2 hours; the above-mentioned dried fibers were dispersed in an aqueous ethanol dispersion (volume ratio 3:1), and crushed into short fibers using a high-speed shear mixer. Obtain the short fiber dispersion liquid, vacuum filter, dry at room temperature, obtain graphene oxide fiber non-woven fabric, select hydroiodic acid to make graphene fiber non-woven fabric by its partial reduction, the diameter of graphene fiber non-woven fabric fiber is 20 μm , the reaction time is 6h, the mass ratio of graphene oxide fiber non-woven fabric to hydroiodic acid is 1:1.

[0041] (2) Preparation of composite fiber fabric...

Embodiment 2

[0044] (1) Preparation of graphene fiber non-woven fabrics: the graphene oxide aqueous dispersion with a concentration of 30mg / mL is the spinning stock solution, and the mixed solution of 15wt% KOH and NaOH is the coagulation bath, which is continuously wet-spun to obtain Graphene oxide fibers were left standing at room temperature for 24 hours, and then vacuum-dried at 100°C for 24 hours; the above-mentioned dried fibers were dispersed in aqueous ethanol solution (volume ratio 1:1), and crushed into short fibers using a high-speed shear mixer , to obtain the short fiber dispersion, vacuum filtration, and drying at room temperature to obtain a graphene oxide fiber non-woven fabric, select hydrazine hydrate to partially reduce it to obtain a graphene fiber non-woven fabric, the diameter of the graphene fiber non-woven fabric fiber is 100 μm, The reaction time is 10 hours, and the mass ratio of graphene oxide fiber nonwoven fabric to hydrazine hydrate is 1:1.

[0045] (2) Prepar...

Embodiment 3

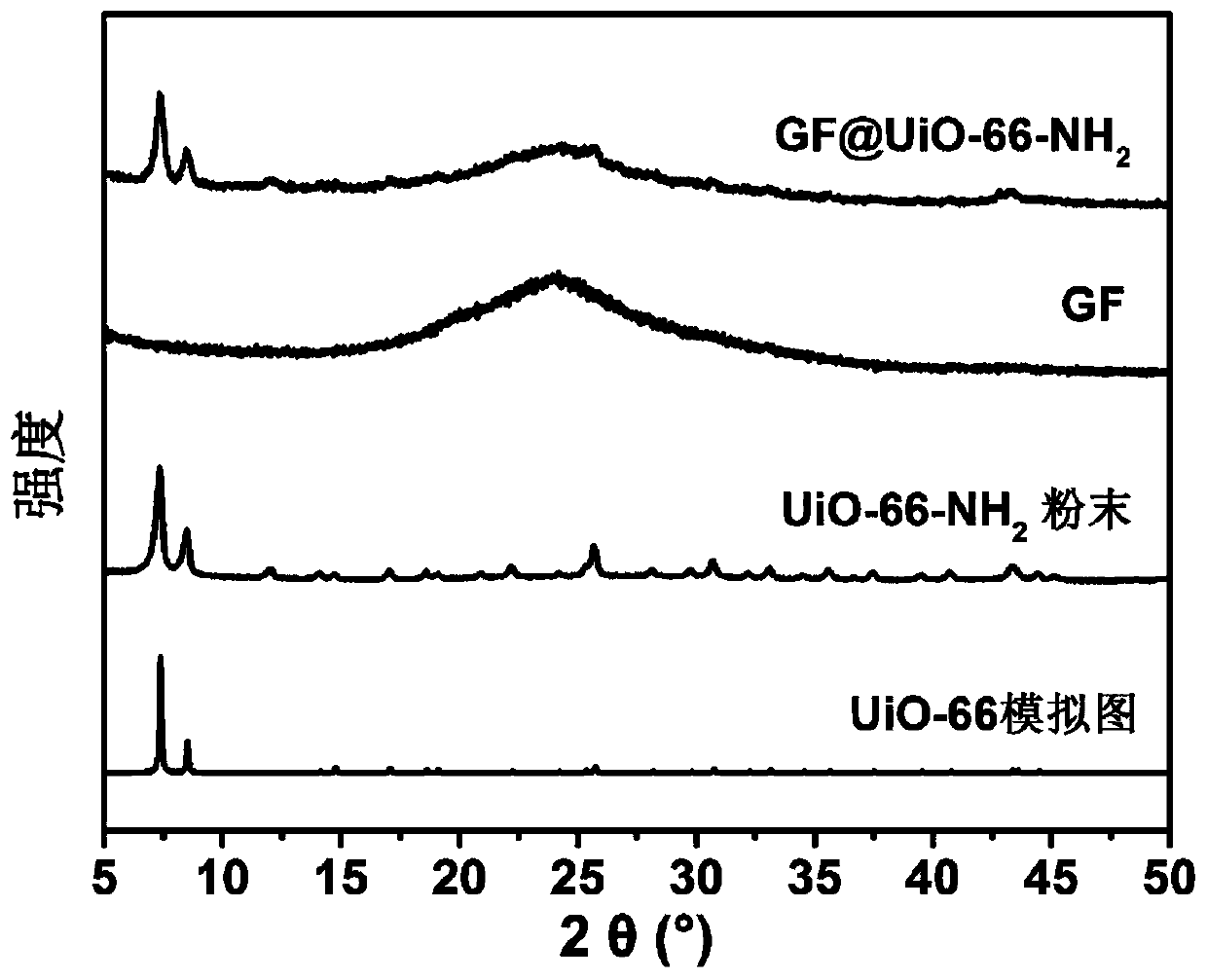

[0048] (1) Preparation of graphene fiber non-woven fabric: the graphene oxide aqueous dispersion with a concentration of 20mg / mL is the spinning stock solution, and 10wt% CaCl 2 The solution is a coagulation bath, and continuous wet spinning is used to prepare graphene oxide fibers, which are left at room temperature for 12 hours, and then vacuum-dried at 60°C for 6 hours; the dried fibers are dispersed in an aqueous ethanol solution (volume ratio 1:3), Use a high-speed shear mixer to crush it into short fibers to obtain a dispersion of short fibers, vacuum filter, and dry at room temperature to obtain a graphene oxide fiber non-woven fabric, which is partially reduced with ascorbic acid to obtain a graphene fiber non-woven fabric , the diameter of the graphene fiber non-woven fabric fiber is 80 μm, the reaction time is 8 h, and the mass ratio of the graphene oxide fiber non-woven fabric to hydrazine hydrate is 1:1. The X-ray diffraction spectrum of prepared graphene fiber is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com