Lithium battery cathode active material and preparation method and application thereof

A positive active material, lithium battery technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problem of limited stability improvement of lithium nickel manganate materials, etc., to improve electrochemical performance, improve stability, The effect of excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 18g of LiNi 0.5 mn 1.5 o 4 Materials (purchased from Shandong Qixing Energy Materials Co., Ltd.) and 0.267g Li 2 SO 4 Mix evenly, and calcinate the obtained mixture in oxygen at 900°C for 5h, with a heating rate of 3°C / min and a cooling rate of 5°C / min.

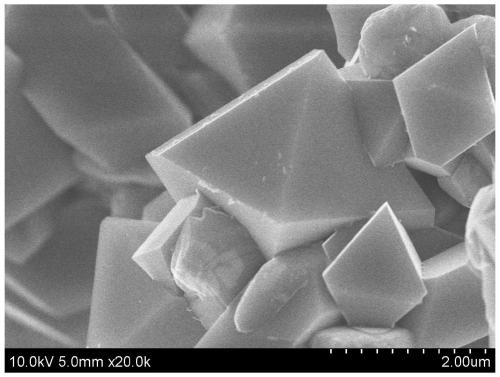

[0041] figure 1 The SEM picture of the original lithium nickel manganese oxide material is shown, and it can be seen that the crystal plane of the lithium nickel manganese oxide material is mainly the [100] plane.

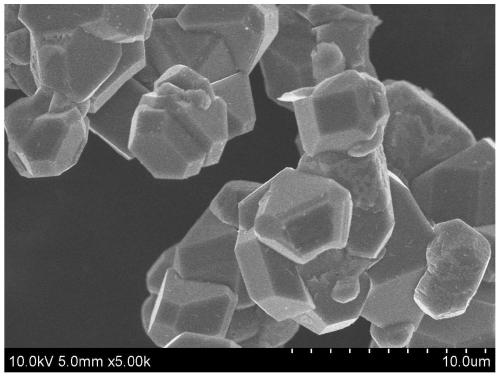

[0042] figure 2 The SEM picture of the lithium nickel manganese oxide material prepared in Example 1 is shown. from figure 2 It can be seen that after surface modification by sulfur element, the crystal plane of lithium nickel manganese oxide material changes from [100] to [111] plane.

Embodiment 2

[0044] 18g of LiNi 0.4 mn 1.6 o 4 Materials (purchased from Shandong Qixing Energy Materials Co., Ltd.), 0.54g of ammonium sulfate and 1g of citric acid were uniformly mixed, and the resulting mixture was calcined in oxygen at 800°C for 6h, with a heating rate of 3°C / min and a cooling rate of 5°C / min .

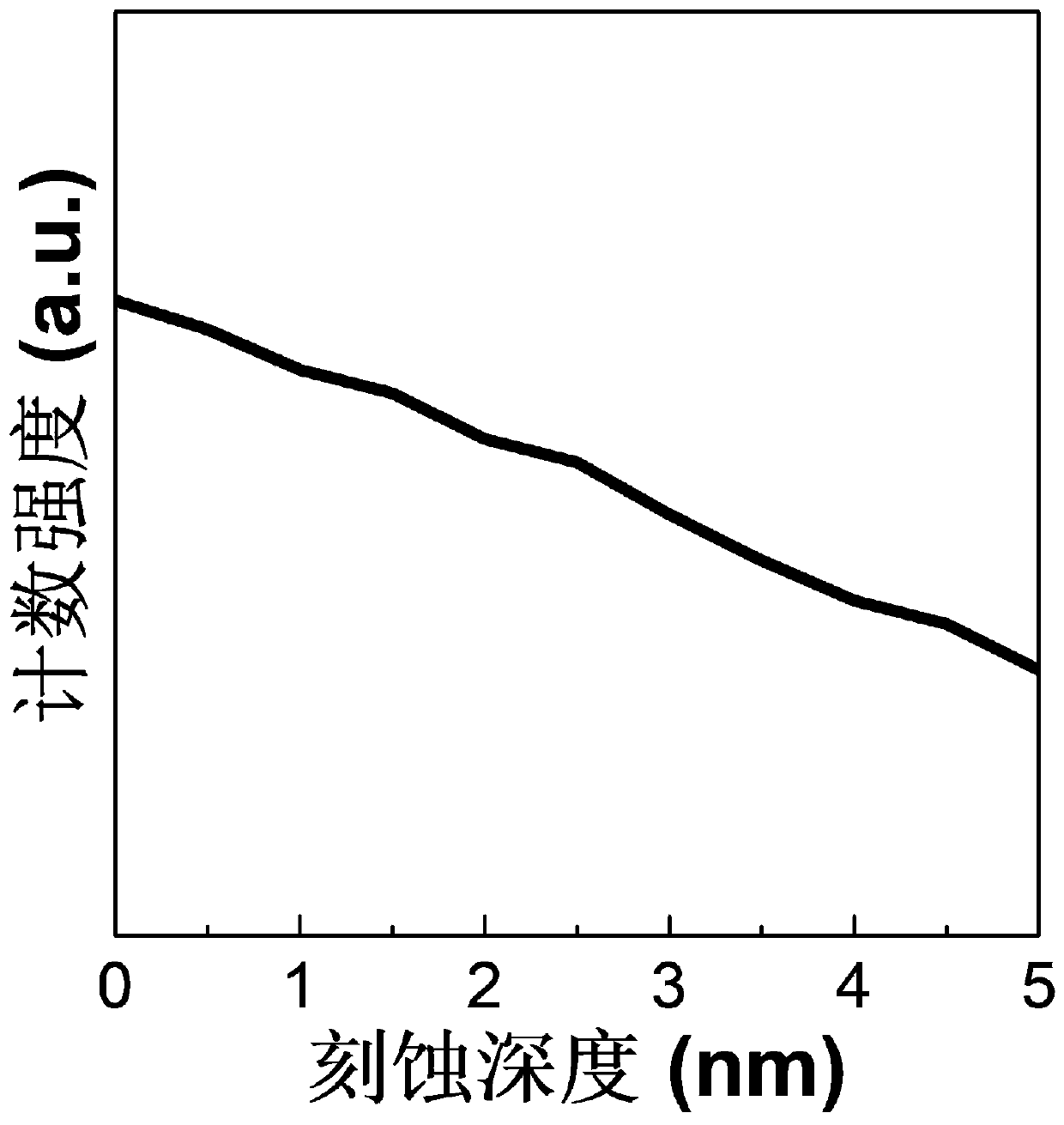

[0045] image 3 Shows the LiNi after the surface sulfur element modification that embodiment 2 makes 0.4 mn 1.6 o 4 Using XPS to characterize the relative content of sulfur on the surface at different etching depths, we can see that the content of sulfur decreases from the surface to the interior as the etching depth increases.

[0046] Next, the positive electrode active material of the lithium battery prepared in Example 1 was assembled into a button battery according to the following steps.

[0047] (1) Preparation of positive pole piece

[0048] The lithium battery cathode active material prepared in Example 1, carbon black as a conductive additive and polyvinylide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com