Polyphosphazene composite flame retardant additive for lithium battery electrolyte and preparation method thereof

A composite flame retardant and polyphosphazene technology, which is applied in the manufacture of lithium batteries, electrolyte batteries, secondary batteries, etc., can solve the problems of reducing the conductivity of the electrolyte, deteriorating battery performance, and limiting applications, so as to reduce the increase in viscosity, Stable structure and improved electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

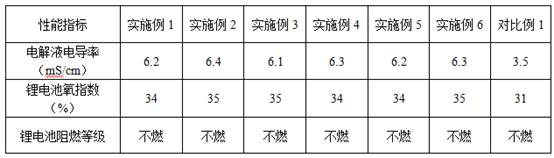

Examples

Embodiment 1

[0026] (1) Add hexachlorocyclotriphosphazene into 1,2,4-trichlorobenzene, stir until completely dissolved, then add sulfamic acid, heat to 120°C for 8 hours, and filter to obtain a solid, first use absolute ethanol Wash 3 times, then wash 3 times with deionized water, and dry in vacuum at 70°C for 24 hours to obtain chain polydichlorophosphazene; hexachlorocyclotriphosphazene, 1,2,4-trichlorobenzene, sulfonic acid The mass ratio of the catalyst is 5:100:0.5;

[0027] (2) Add polydichlorophosphazene to absolute ethanol, ultrasonically disperse for 20 minutes, then add tetramethoxysilane, stir and react at room temperature for 30 minutes, and filter with suction to obtain polybis(trimethoxysiloxy)phosphazene ; The mass ratio of polydichlorophosphazene, tetramethoxysilane, and dehydrated alcohol is 6:20:100;

[0028] (3) Add polybis(trimethoxysiloxy)phosphazene to magnesium chloride solution with a mass concentration of 5%, hydrolyze to obtain polybis(trihydroxysiloxy)phosphazen...

Embodiment 2

[0030] (1) Add hexachlorocyclotriphosphazene into 1,2,4-trichlorobenzene, stir until completely dissolved, then add trifluoromethanesulfonic acid, heat to 140°C for 6 hours, and filter to obtain a solid. Wash 3 times with water and ethanol, then wash 3 times with deionized water, and dry in vacuum at 90°C for 18 hours to obtain chain polydichlorophosphazene; hexachlorocyclotriphosphazene, 1,2,4-trichlorobenzene, The mass ratio of sulfonic acid catalyst is 10:100:0.8;

[0031] (2) Add polydichlorophosphazene to absolute ethanol, ultrasonically disperse for 40 minutes, then add tetramethoxysilane, stir and react at room temperature for 50 minutes, and filter with suction to obtain polybis(trimethoxysiloxy)phosphazene ; The mass ratio of polydichlorophosphazene, tetramethoxysilane, and dehydrated alcohol is 8:20:100;

[0032] (3) Add polybis(trimethoxysiloxy)phosphazene to magnesium chloride solution with a mass concentration of 10%, hydrolyze to obtain polybis(trihydroxysiloxy)...

Embodiment 3

[0034] (1) Add hexachlorocyclotriphosphazene into 1,2,4-trichlorobenzene, stir until completely dissolved, then add sulfamic acid, heat to 130°C for 7 hours, and filter to obtain a solid, first use absolute ethanol Wash 3 times, then wash 3 times with deionized water, and dry in vacuum at 80°C for 22 hours to obtain chain polydichlorophosphazene; hexachlorocyclotriphosphazene, 1,2,4-trichlorobenzene, sulfonic acid The mass ratio of the catalyst is 7:100:0.6;

[0035] (2) Add polydichlorophosphazene to absolute ethanol, ultrasonically disperse for 30 minutes, then add tetramethoxysilane, stir and react at room temperature for 40 minutes, and filter with suction to obtain polybis(trimethoxysiloxy)phosphazene ; The mass ratio of polydichlorophosphazene, tetramethoxysilane, and dehydrated alcohol is 7:20:100;

[0036](3) Add polybis(trimethoxysilyloxy)phosphazene to magnesium chloride solution with a mass concentration of 8%, hydrolyze to obtain polybis(trihydroxysiloxy)phosphaze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com