Method for producing alginate hydrolysate

A technology for producing brown algae and alginate lyase, which is applied in the field of production of alginate hydrolyzate, can solve the problems of low degradation rate, unreachable, low viscosity, etc., and achieve the effect of high hydrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The preparation method involved in the following examples is as follows:

[0058] The preparation method of alginate lyase is as follows:

[0059] In a sterile environment, use an inoculation loop to dip the Vibrio natriegens SK42.001 bacterial solution stored in a glycerol tube, streak it on a sodium alginate solid plate, and place it in a constant temperature incubator at 37°C for 15 hours. , to obtain a single colony; in a sterile environment, pick a single colony and inoculate it into a 50mL seed medium, and cultivate it at 28°C and 200rpm for 12h to obtain a seed liquid; ) was inoculated into 50mL fermentation medium, cultivated at 28°C and 200rpm for 24h to obtain a fermentation broth; the fermentation broth was centrifuged at 10000r / min for 5min, and the alginate-containing lyase (amino acid sequence as shown in SEQ ID NO: 1) was taken ) of the fermentation supernatant (enzyme activity 1.4U / mL).

Embodiment 1

[0060] Embodiment 1: the preparation of alginate hydrolyzate (one-step method)

[0061] Specific steps are as follows:

[0062] Firstly, the alginate lyase was mixed according to 2.5U / g 褐藻胶 , 3.75U / g 褐藻胶 , 5U / g 褐藻胶 , 7.5U / g 褐藻胶 , 10U / g 褐藻胶 The addition amount of 10g / L alginate is added to the reaction system containing 10g / L alginate (the reaction system containing 10g / L alginate is the alginate solution with a concentration of 10g / L), and the reaction is carried out at a temperature of 35°C and a pH of 7. 6h, the reaction solution 1-5 was obtained, and then the reaction solution was separated to obtain the alginate hydrolyzate 1-5; the separation was firstly adding anhydrous water and ethanol to obtain a mixed solution, and then the mixed solution was left to stand for 24 hours, then centrifuged at 8000 rpm and 25° C. for 15 minutes to obtain a precipitate to obtain alginate hydrolyzate.

[0063] The concentration of the alginate hydrolyzate in the reaction solutions 1-...

Embodiment 2

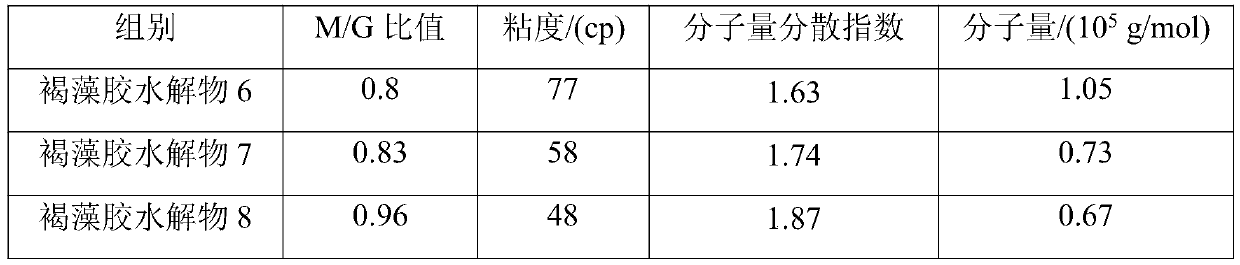

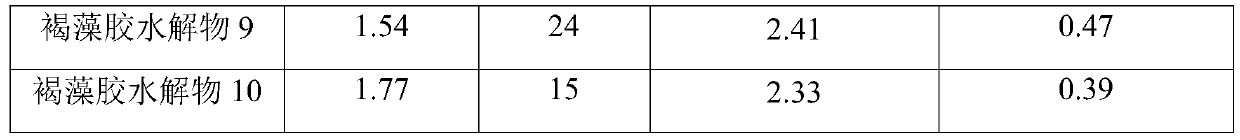

[0070] Embodiment 2: the preparation of algin hydrolyzate (batch method)

[0071] Specific steps are as follows:

[0072] Option 1: First add alginate lyase at 2.5U / g 褐藻胶 The addition amount of 10g / L alginate is added to the reaction system containing 10g / L alginate (the reaction system containing 10g / L alginate is the alginate solution with a concentration of 10g / L), and the reaction is carried out at a temperature of 35°C and a pH of 7. 6h to obtain the reaction solution 6, and then separate the reaction solution to obtain the alginate hydrolyzate 6; 反应体系 The amount of addition is to dissolve the alginate in the reaction system through a high-speed disperser, and then according to 2.5U / g 褐藻胶 Alginate lyase is added to the reaction system; the separation is to first add absolute ethanol to the reaction solution according to the volume ratio of 1:3 (reaction solution: absolute ethanol) to obtain a mixed solution, and then mix the mixed solution After standing still for 24 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com