Benzene ring-containing amide block polymer modified polycarboxylate water reducer and preparation method thereof

A benzene ring amide block and polymer technology, which is applied in the field of building materials, can solve the problems of large slump loss over time and poor workability, and achieve the effects of reducing rigidity, simple and easy to operate in the preparation process, and easy to bend

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

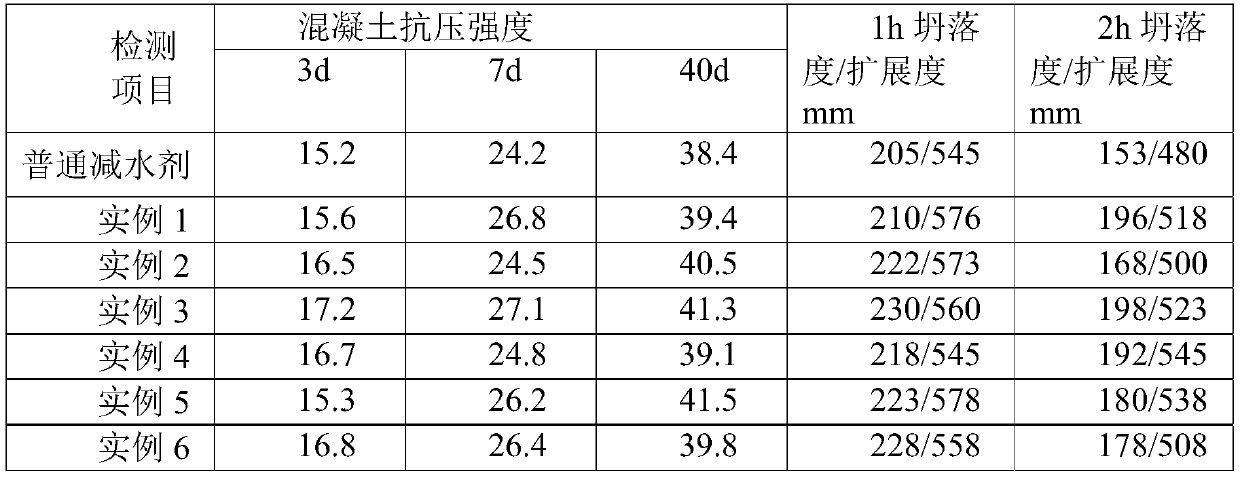

Examples

example 1

[0022] The described polycarboxylate water reducer modified with benzene ring amide block polymer and its preparation method is mainly prepared from the following components: vinyl butyl ether polyoxyethylene ether: 350 parts; acrylic acid: 32 parts 4-(acrylamide) benzoic acid: 8 parts; 1-allyl-2-fluorobenzene: 10 parts; dibenzoyl peroxide: 0.5 parts; azobisisoheptanonitrile: 1.2 parts; Isobutylcyanoformyl: 1.5 parts; mercaptoethanol: 1.3 parts; the rest is water, with a total mass of 1000 parts and a solid content of 40%.

[0023] Described a kind of polymer-modified polycarboxylate water-reducer containing benzene ring amide block and preparation method thereof, the specific preparation process is as follows:

[0024] 1) Preparation of benzene ring amide block: add 10 parts of 1-allyl-2-fluorobenzene, 8 parts of dibenzoyl peroxide and 50 parts of deionized water into the No. The initiator is added dropwise, that is, a mixed solution of 0.5 parts of dibenzoyl peroxide and 50...

example 2

[0028]The described polycarboxylate water reducer modified with benzene ring amide block polymer and its preparation method is mainly prepared from the following components: vinyl butyl ether polyoxyethylene ether: 352 parts; acrylic acid: 30 parts 2-acrylamidophenylboronic acid: 5 parts; 1-allyl-4-fluorobenzene: 9 parts; lauryl peroxide: 0.6 parts; dimethyl azobisisobutyrate: 1.3 parts; Diisobutyronitrile: 1.7 parts; mercaptopropanol: 1.8 parts; the rest is water, with a total mass of 1000 parts and a solid content of 40%.

[0029] Described a kind of polymer-modified polycarboxylate water-reducer containing benzene ring amide block and preparation method thereof, the specific preparation process is as follows:

[0030] 1) Preparation of cyclic amide block: add 9 parts of 1-allyl-4-fluorobenzene, 5 parts of 2-acrylamide phenylboronic acid and 50 parts of deionized water into the No. The initiator is added dropwise, which is a mixed solution of 0.6 parts of lauryl peroxide an...

example 3

[0034] The described polycarboxylate water reducer modified with benzene ring amide block polymer and its preparation method is mainly prepared from the following components: vinyl butyl ether polyoxyethylene ether: 355 parts; acrylic acid: 28 parts 4-vinylbenzamide: 6 parts; 1-phenylvinylboronic acid: 7 parts; dibenzoyl peroxide: 0.7 parts; azobisisoheptanonitrile: 1.4 parts; Acyl: 2 parts; mercaptoethanol: 1.6 parts; the rest is water, the total mass is 1000 parts, and the solid content is 40%.

[0035] Described a kind of polymer-modified polycarboxylate water-reducer containing benzene ring amide block and preparation method thereof, the specific preparation process is as follows:

[0036] 1) Preparation of benzene cyclic amide block: Add 7 parts of 1-phenylvinylboronic acid, 6 parts of 4-vinylbenzamide and 50 parts of deionized water into the No. 1 reaction kettle and stir evenly, then dropwise add The initiator is a mixed solution of 0.7 parts of dibenzoyl peroxide and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com