UV hybrid curable OLED sealant composition

A technology of hybrid curing and composition, applied in the direction of adhesives, adhesive types, epoxy resin glue, etc., to achieve the effect of good coating operability, high bonding strength, and excellent resistance to water and oxygen penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

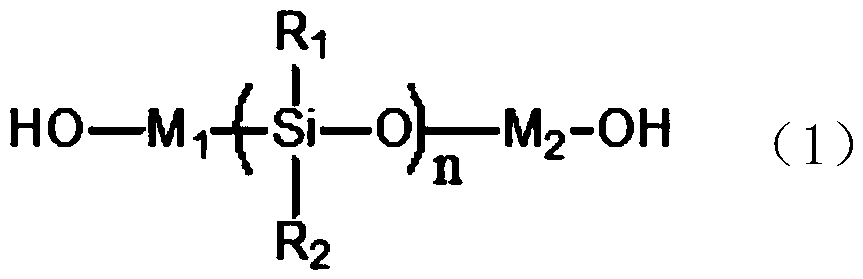

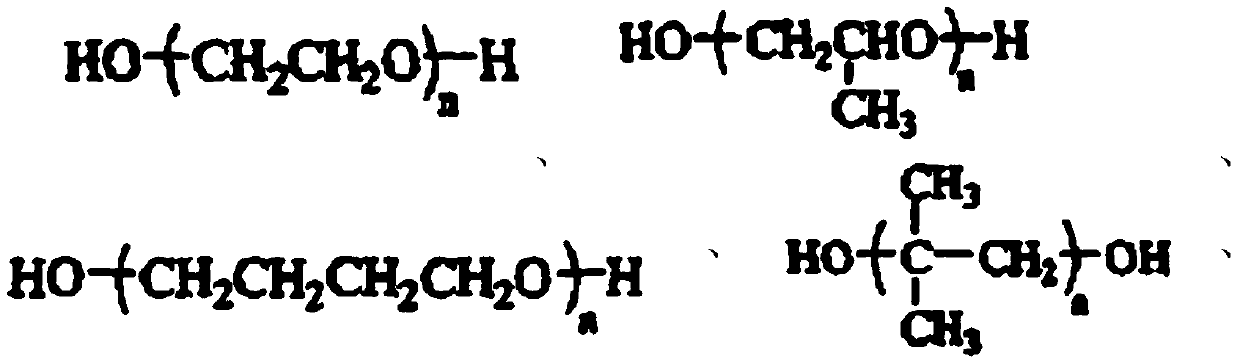

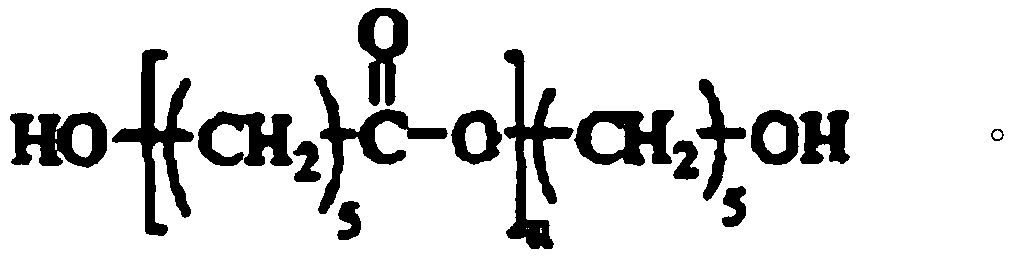

Method used

Image

Examples

Embodiment 1

[0051] This embodiment provides a UV hybrid curable OLED sealant composition, which is prepared by mixing the components in the following parts by weight:

[0052]

[0053] The UV hybrid curable functional organosiloxane is self-made, and by weight, the materials required for the resin synthesis reaction are:

[0054]

[0055] The preparation method of the UV hybrid curable functional organosiloxane comprises the following specific steps:

[0056] Step A: Prepare the various component materials required for the above resin synthesis reaction by weight.

[0057] Step B: Add the TDI trimer and DBTL weighed in step A to a four-necked flask equipped with a stirrer, a thermometer, a condenser tube, a nitrogen pipe and a constant pressure funnel; , slowly drop dihydroxypolydiphenylsiloxane from the constant pressure funnel, after the dropwise addition, slowly raise the temperature, control the reaction temperature below 45 ° C, measure the content of isocyanate every half an ...

Embodiment 2

[0060] This embodiment provides a UV hybrid curable OLED sealant composition, which is prepared by mixing the components in the following parts by weight:

[0061]

[0062] The UV hybrid curable functional organosiloxane is self-made, and by weight, the materials required for the resin synthesis reaction are:

[0063]

[0064] The preparation method of the UV hybrid curable functional organosiloxane comprises the following specific steps:

[0065] Step A: Prepare the various component materials required for the above resin synthesis reaction by weight.

[0066] Step B: Add the IPDI trimer and DBTL weighed in step A to a four-necked flask equipped with a stirrer, a thermometer, a condenser tube, a nitrogen pipe and a constant pressure funnel; , slowly drop dihydroxypolydimethylsiloxane from the constant pressure funnel, after the dropwise addition, slowly raise the temperature, control the reaction temperature below 45 ° C, measure the content of isocyanate every half an...

Embodiment 3

[0069] This embodiment provides a UV hybrid curable OLED sealant composition, which is prepared by mixing the components in the following parts by weight:

[0070]

[0071] The UV hybrid curable functional organosiloxane is self-made, and by weight, the materials required for the resin synthesis reaction are:

[0072]

[0073]

[0074] The preparation method of the UV hybrid curable functional organosiloxane comprises the following specific steps:

[0075] Step A: Prepare the various component materials required for the above resin synthesis reaction by weight.

[0076] Step B: Add the MDI trimer and DBTL weighed in step A in a four-necked flask equipped with a stirrer, a thermometer, a condenser, a nitrogen pipe and a constant pressure funnel; , slowly drop dihydroxypolydimethylsiloxane from the constant pressure funnel, after the dropwise addition, slowly raise the temperature, control the reaction temperature below 45 ° C, measure the content of isocyanate every h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com