A carbon nanotube-aluminum nitride wave absorbing agent and its preparation method, a carbon nanotube-aluminum nitride composite wave absorbing material and its application

A technology of carbon nanotubes and aluminum nitride, which is applied in the field of wave-absorbing materials, can solve problems such as large surface energy, affecting the uniform dispersion of carbon nanotubes, and small diameters of carbon nanotubes, and achieves the effect of simple operation and suitable for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention provides the preparation method of the carbon nanotube-aluminum nitride wave absorbing agent described in the above technical scheme, comprising the following steps:

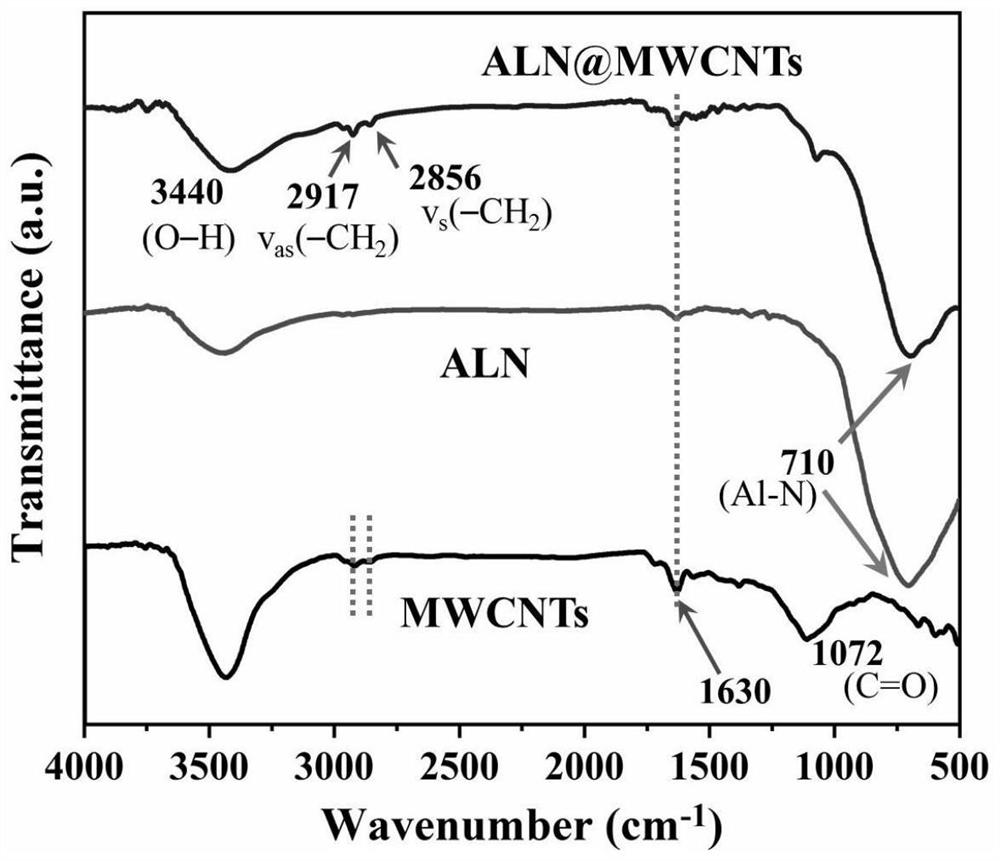

[0045] The carbon nanotube, aluminum nitride and anhydrous dispersant are mixed and modified to obtain the carbon nanotube-aluminum nitride wave absorbing agent.

[0046] In the present invention, the anhydrous dispersant preferably includes N,N-dimethylformamide or absolute ethanol, more preferably N,N-dimethylformamide. In the present invention, the aluminum nitride is easily hydrolyzed with water, and the present invention uses an anhydrous dispersant as an anhydrous dispersant, which can avoid side reactions of aluminum nitride, thereby improving the absorption of carbon nanotubes-aluminum nitride. The absorbing performance of the agent. In the present invention, the ratio of the mass of the carbon nanotubes to the volume of the anhydrous dispersant is preferably 1 g: (2-4) L, m...

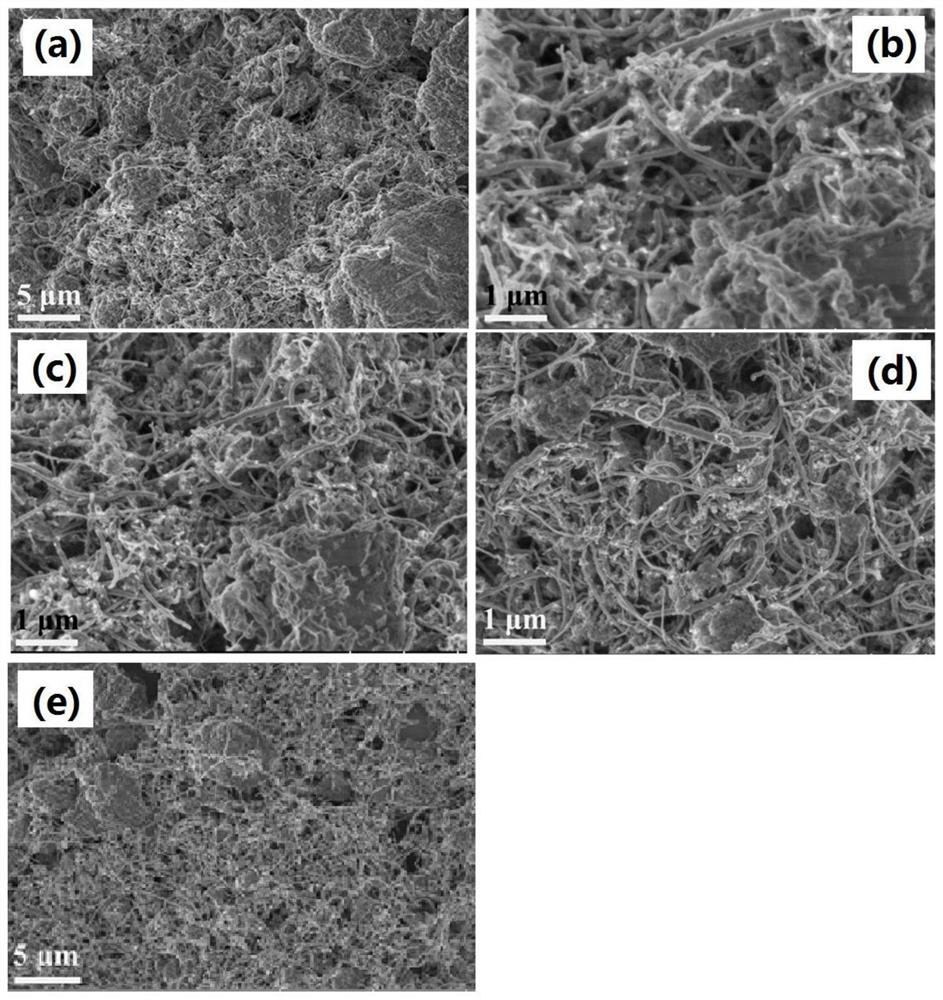

Embodiment 1

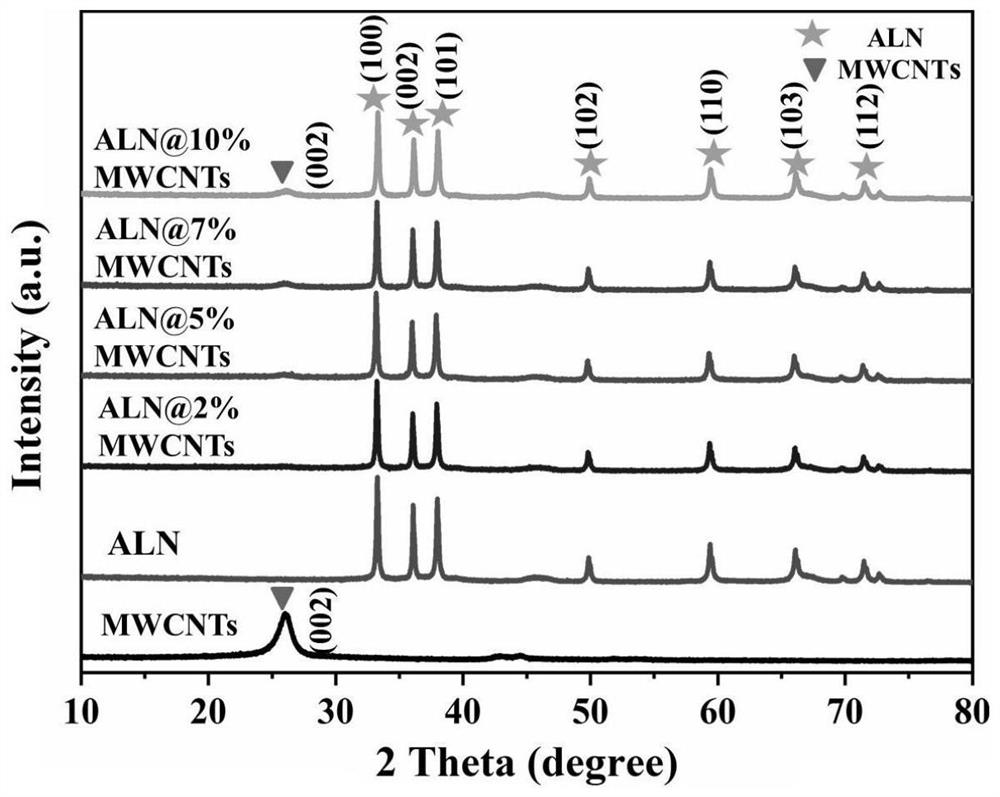

[0065] Add 300mL of DMF to a beaker with a capacity of 500mL, add 20mg of multi-walled carbon nanotubes (MWCNTs, mostly 5-8μm in length, 30-35nm in diameter, and about 0.06nm in wall thickness) and 0.98g of aluminum nitride, Place the beaker in an ultrasonic machine for ultrasonic dispersion for 1 hour to obtain a mixed solution; transfer the mixed solution to a round-bottomed flask, put a magnet, add a condenser tube to one side of the round-bottomed flask, and fix the experimental device in an oil bath The modification process was started in the middle, and under the condition of magnetic stirring, the temperature was raised to 130° C. at a heating rate of 3.5° C. / min, and then the modification reaction was performed for 9 hours. After the reaction, the whole experimental device was naturally cooled to room temperature, and then the round bottom flask was taken out; the obtained wave absorbing agent solution was suction filtered to obtain a solid; the solid was washed with ab...

Embodiment 2

[0067] Add 300mL of DMF to a beaker with a capacity of 500mL, add 100mg of multi-walled carbon nanotubes (mostly 5-8μm in length, 30-35nm in diameter, and about 0.06nm in wall thickness) and 1.9g of aluminum nitride in the beaker. Place in an ultrasonic machine for ultrasonic dispersion for 1.5 hours to obtain a mixed solution; transfer the mixed solution to a round-bottomed flask, put a magnet, add a condenser tube to one side of the round-bottomed flask, and fix the experimental device in an oil bath The oil bath experiment was started, and under the condition of magnetic stirring, the temperature was raised to 120° C. at a heating rate of 3.5° C. / min and then reacted for 8 hours. After the reaction, the whole experimental device was naturally cooled to room temperature, and then the round bottom flask was taken out; the obtained wave absorbing agent solution was suction filtered to obtain a solid; the solid was washed with absolute ethanol and ultrapure water in sequence, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com