Dual-drive dispersion strengthening heavy oil hydrogenation reaction system and process

A dispersion strengthening and heavy oil hydrogenation technology, which is applied in the petroleum industry, processing hydrocarbon oil, refining to remove heteroatoms, etc., can solve the problems of catalyst wear, low heat transfer efficiency, uneven temperature field distribution, etc., and achieve total mass transfer The effect of speed increase, specific phase boundary area increase, and synergistic matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

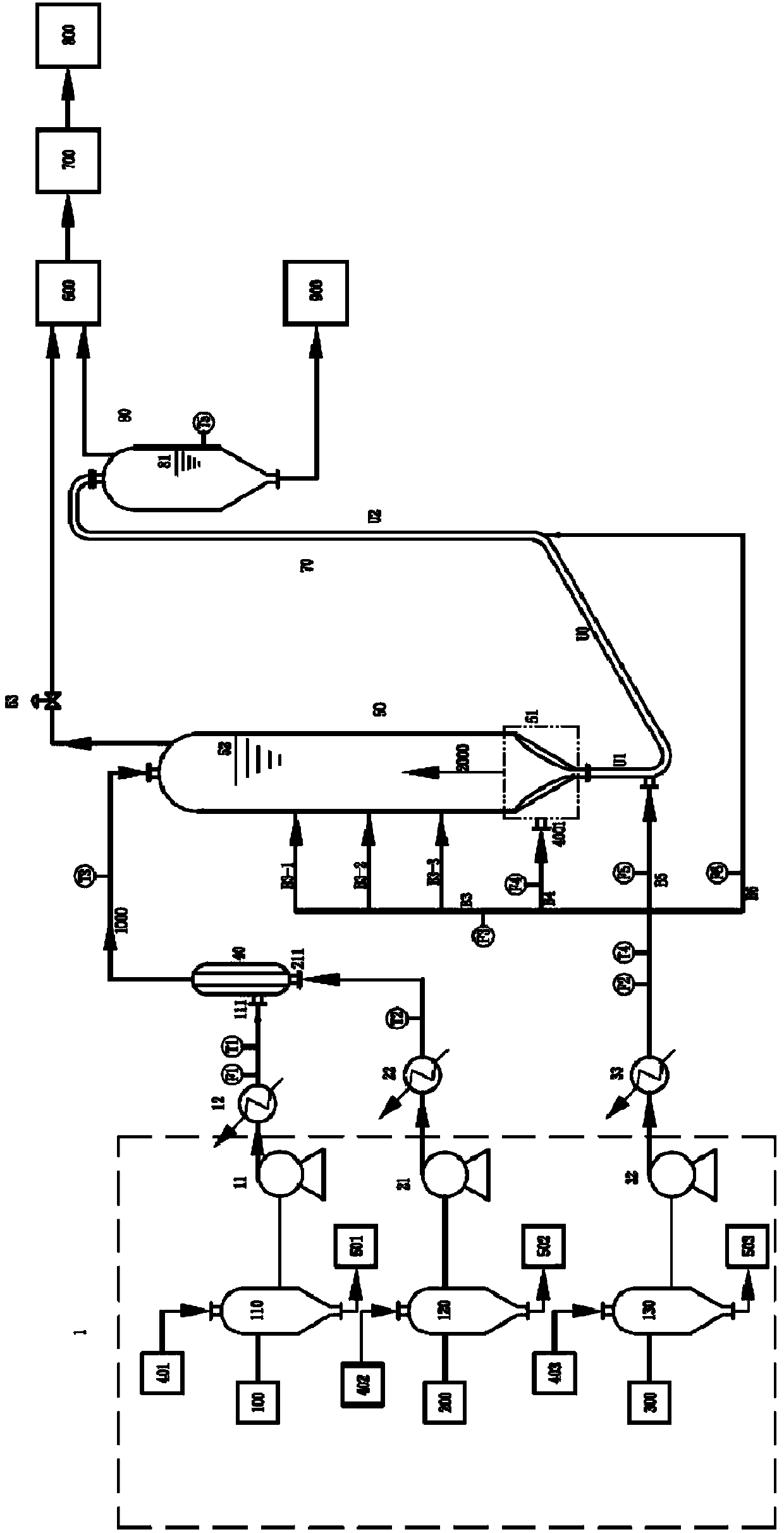

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0034] see figure 1 , the present invention includes a feed system 1 communicated with the servo driver 40, the dispersion enhanced reactor 50 and the U-shaped reactor 70 respectively;

[0035] The U-shaped reactor 70 is divided into U1 section, U0 section, and U2 section connected in sequence;

[0036] The dispersion enhanced reactor 50 includes a material inlet connected to the outlet of the servo drive 40 at the upper end, a material outlet connected to the secondary online flow divider 600 through the control valve 53, and a driving conduit 4001 at the lower end, and A main driver 51 is provided at the entrance of the internal driving conduit 4001 of the dispersion enhanced reactor 50, and a heavy oil material outlet connected to the entrance of the U-shaped reactor 70 is opened at the bottom;

[0037] The feed system includes a servo feeder and a react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com