Preparation method of Zr-Si-O amorphous protective coating for nuclear power

A protective coating, zr-si-o technology, applied in coatings, nuclear power generation, metal material coating technology, etc., can solve the problems of volume expansion, weak toughness and high hardness, etc., to improve service life, good resistance Oxidation property, effect of uniform coating composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Choose Zr-4 and pure Si target as the sputtering target, use a single crystal silicon wafer as the coating substrate, conduct ultrasonic treatment with acetone, alcohol, and deionized water for 20 minutes, and then dry it with a high-purity nitrogen gun for later use; When the chamber vacuum reaches 5×10 -4 At around mbar, the Zr-4 layer is deposited first. Connect the Zr-4 target to a target site connected to a direct current (DC) power supply. Connect the Si target to a target site connected to a radio frequency (RF) power source. The air pressure in the chamber reaches 5×10 -4 When it is below Pa, open the process gas valve to feed Ar, set the gas flow rate of Ar to 20sccm through the gas flow meter, and adjust the air pressure in the vacuum chamber to 0.5 Pa (±0.01Pa) by adjusting the plug valve of the molecular pump ; Turn on the DC power supply, adjust the current of the DC power supply to 0.400A (±0.005A), the voltage to 190V (±2V), and start sputtering coati...

Embodiment 2

[0038] Choose Zr-4 and pure Si target as the sputtering target, use a single crystal silicon wafer as the coating substrate, conduct ultrasonic treatment with acetone, alcohol, and deionized water for 20 minutes, and then dry it with a high-purity nitrogen gun for later use; When the chamber vacuum reaches 5×10 -4 At around mbar, the Zr-4 layer is deposited first. Connect the Zr-4 target to a target site connected to a direct current (DC) power supply. Connect the Si target to a target site connected to a radio frequency (RF) power source. The air pressure in the chamber reaches 5×10 -4 When it is below Pa, open the process gas valve to feed Ar, set the gas flow rate of Ar to 20sccm through the gas flow meter, and adjust the air pressure in the vacuum chamber to 0.5 Pa (±0.01Pa) by adjusting the plug valve of the molecular pump ; Turn on the DC power supply, adjust the current of the DC power supply to 0.400A (±0.005A), the voltage to 190V (±2V), and start sputtering coati...

example 1

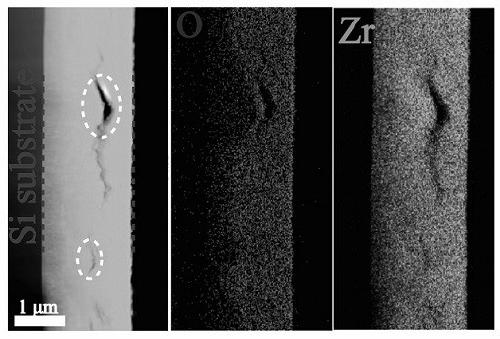

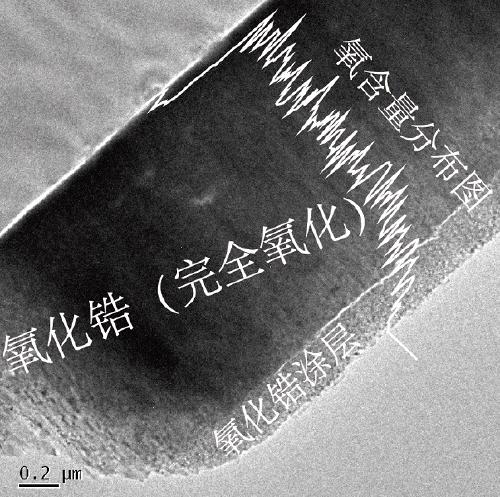

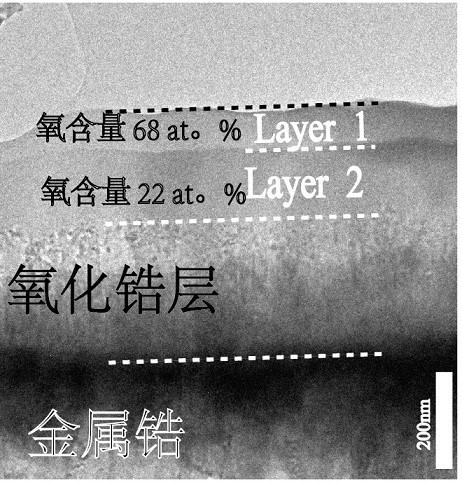

[0048] The result of the coating in Example 1 after a long-time air oxidation experiment is as follows: image 3 As shown, according to the EDS composition analysis, it can be seen that as the oxidation progresses, the amorphous Zr-Si-O thin film evolves into a stable double-layer structure, and the interface is well bonded. As the oxidation time increases, the thickness of the zirconium oxide layer below is limited, forming a typical parabolic form, and the layer2 layer tends to be stable, such as Figure 4 As shown, compared with the traditional zirconia passivation layer, it exhibits good oxidation resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com