Metal-organic framework film preparation solution, metal-organic framework film and preparation method of metal-organic framework film

An organic framework and metal technology, applied in the field of metal-organic framework membrane and its preparation, can solve the problems of heavy metal chromium pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

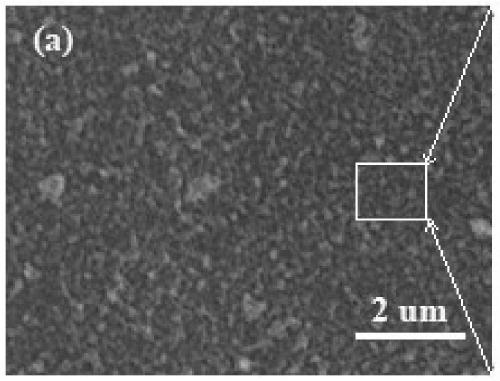

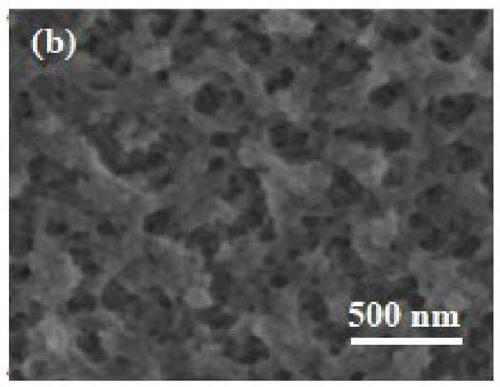

Image

Examples

Embodiment 1

[0086] Metal-organic framework membranes were prepared by the following method:

[0087] (1) Etching treatment is carried out on the metal surface to be treated, and the etching amount is 1.2g / m 2 ;

[0088] (2) Spray the metal-organic framework membrane preparation solution evenly on the surface of the metal to be treated, the spray pressure is 0.03MPa, and the treatment time is 20s to form a metal-organic framework membrane, and the metal-organic framework membrane is prepared The solution includes the following components by weight percentage: 0.3mmol / L of 2,4,6-trihydroxybenzoic acid, 0.5mmol / L of sodium fluozirconate, 0.1mmol / L of dilute sulfuric acid solution of manganese fluoride dihydrate, potassium fluoride 0.1mmol / L, sodium diisooctyl sulfonate maleate 6×10 -6 mmol / L, adjust the pH to 4.2;

[0089] (3) Drying the metal-organic framework membrane at a temperature of 80° C. for 20 minutes.

Embodiment 2

[0091] Metal-organic framework membranes were prepared by the following method:

[0092] (1) Etching treatment is carried out on the metal surface to be treated, and the etching amount is 1.5g / m 2 ;

[0093] (2) Soak the metal to be treated in the metal-organic framework membrane preparation solution for 12 minutes to form a metal-organic framework membrane. The metal-organic framework membrane preparation solution includes the following components by weight percentage: 3,4,5-trihydroxy Benzoic acid 1.0mmol / L, fluorotitanic acid 0.3mmol / L, dilute sulfuric acid solution of manganese fluoride dihydrate 0.5mmol / L, potassium sulfate 0.2mmol / L, diisooctyl ammonium maleate 2× 10 -6 mmol / L, adjust the pH to 2.6;

[0094] (3) Drying the metal-organic framework membrane at a temperature of 100° C. for 10 minutes.

Embodiment 3

[0096] Metal-organic framework membranes were prepared by the following method:

[0097] (1) Etching treatment is carried out on the metal surface to be treated, and the etching amount is 1.3g / m 2 ;

[0098] (2) The metal-organic framework membrane preparation solution is evenly coated on the surface of the metal to be treated, and the treatment time is 20s to form a metal-organic framework membrane. The metal-organic framework membrane preparation solution includes the following components by weight percentage: 3 , 0.2mmol / L of 4,5-trihydroxybenzaldehyde, 0.1mmol / L of ammonium fluorozirconate, 0.3mmol / L of dilute sulfuric acid solution of manganese fluoride dihydrate, 0.5mmol / L of potassium hexafluorochlorate, maleic acid Sodium diisooctyl sulfonate 4×10 -6 mmol / L, adjust the pH to 3.0;

[0099] (3) Drying the metal-organic framework membrane at a temperature of 120° C. for 15 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com