Preparing method of antibacterial three-dimensional porous bone implantation material

A bone implant material and three-dimensional porous technology, applied in electrolytic coatings, pharmaceutical formulations, surface reaction electrolytic coatings, etc., can solve the problems of poor antibacterial performance, improve arc starting ability, antibacterial and antibacterial performance and biological activity , Improve the effect of distribution uniformity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

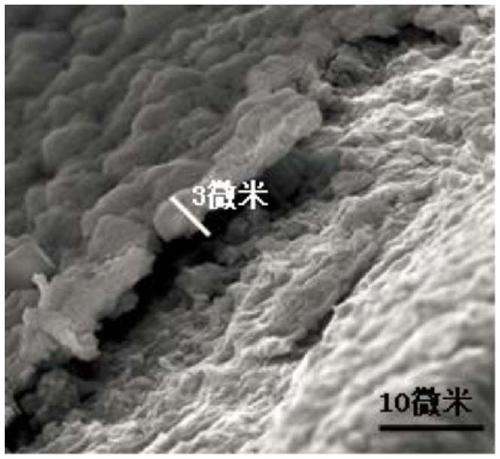

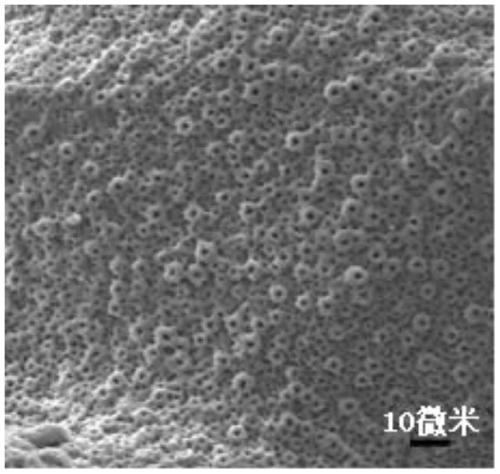

[0025]In a typical implementation of the present application, a method for preparing an antibacterial three-dimensional porous bone implant material is provided, the preparation method comprising: performing surface activation treatment on the three-dimensional porous bone implant material to obtain a pretreated material; The treated material is subjected to micro-arc oxidation treatment to form an in-situ growth film layer with antibacterial ions on the surface of the pretreated material, wherein the electrolyte used in the micro-arc oxidation treatment includes antibacterial ions and functional substances, and the antibacterial ions are selected from zinc ions, copper ions, and Any one or more of ions and silver ions; and hydrothermal treatment is performed on the film layer grown in situ to obtain an antibacterial three-dimensional porous bone implant material.

[0026] This application performs surface activation treatment on the three-dimensional porous bone implant materi...

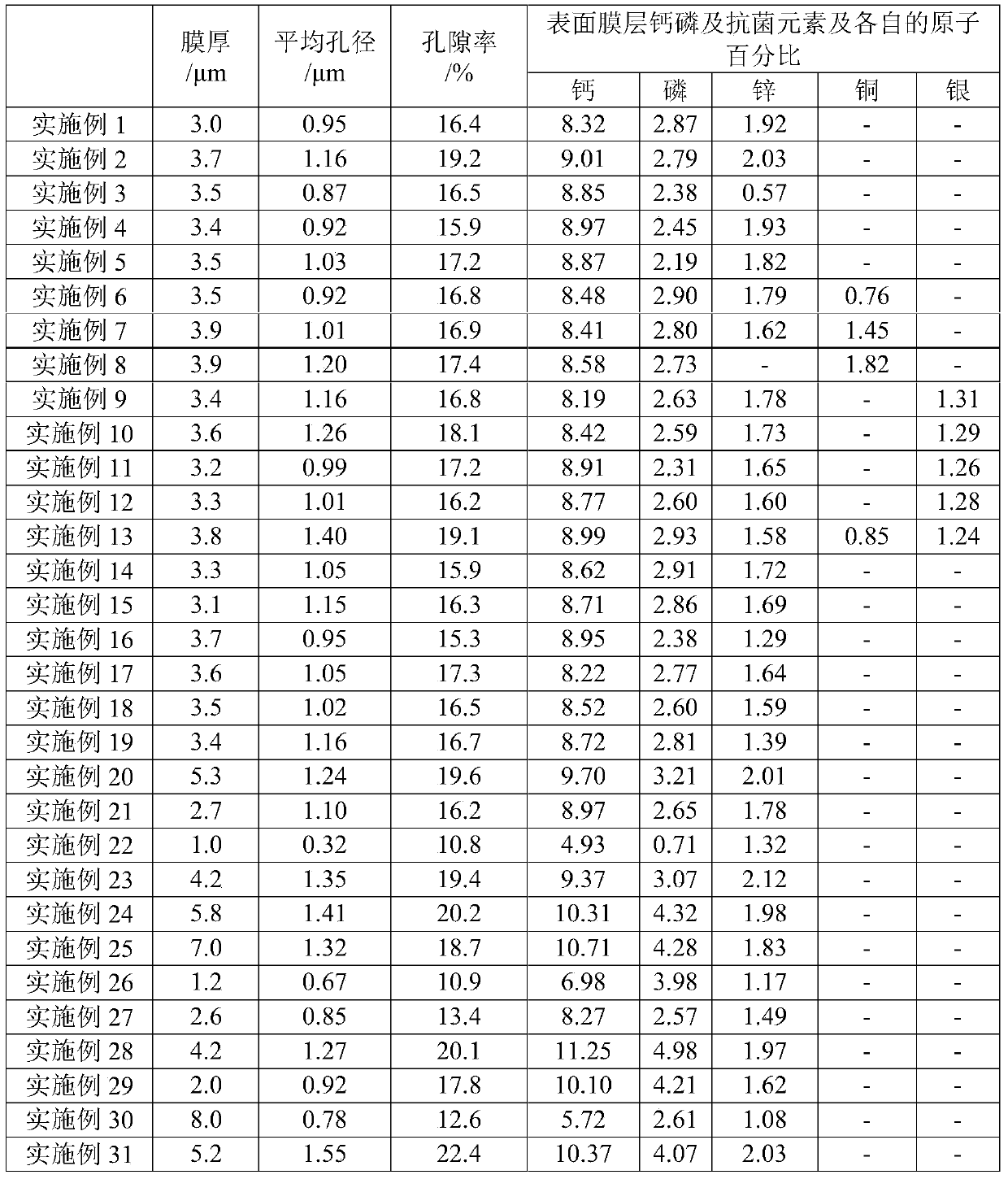

Embodiment 1

[0042] The artificial vertebral body of Ti-6Al-4V is antibacterially treated. The height of the artificial vertebral body is 50mm, the diameter of the inscribed circle of the structural hole of the artificial vertebral body is 5mm, the diameter of the circumscribed circle of the artificial The included angle is 5°, the porosity is 60%, and the average pore diameter is 800 μm.

[0043] Pickling the artificial vertebral body, the volume ratio of the pickling solution is hydrofluoric acid with a concentration of 40%: nitric acid with a concentration of 68%: deionized water = 6:12:82, use the pickling solution to acidify the titanium material After washing for 15 minutes, use deionized water to ultrasonically clean for 10 minutes, then spray, rinse and dry to obtain the pretreated material;

[0044] The pretreated material is used as the anode, and the stainless steel is used as the cathode. The porous material is placed in the electrolyte for micro-arc oxidation, and an in-situ g...

Embodiment 2

[0049] The difference from Example 1 is:

[0050] The concentration of zinc acetate in the electrolyte is 35g / L, and the micro-arc oxidation treatment process conditions are: oxidation voltage 600V, output pulse frequency of power supply 1000Hz, peak current setting 500A, oxidation time 20min. The electrolyte temperature is controlled at about 10°C during the oxidation process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com