Cotton-derived porous carbon electrode material and synthesis method and application thereof

A technology of porous carbon electrodes and porous carbon materials, which is applied in the field of cotton-derived porous carbon electrode materials and their synthesis, can solve problems such as the rare research on composite material templates and carriers, and achieve good electrochemical performance and electrochemical stability, Uniform product shape and increased migration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

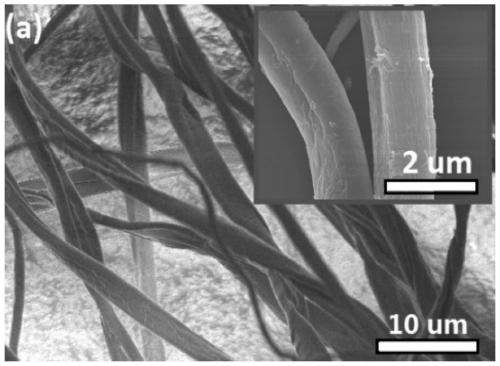

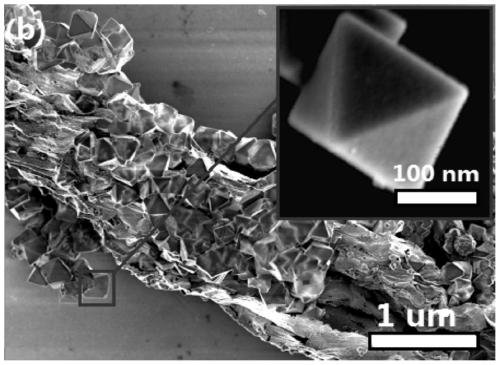

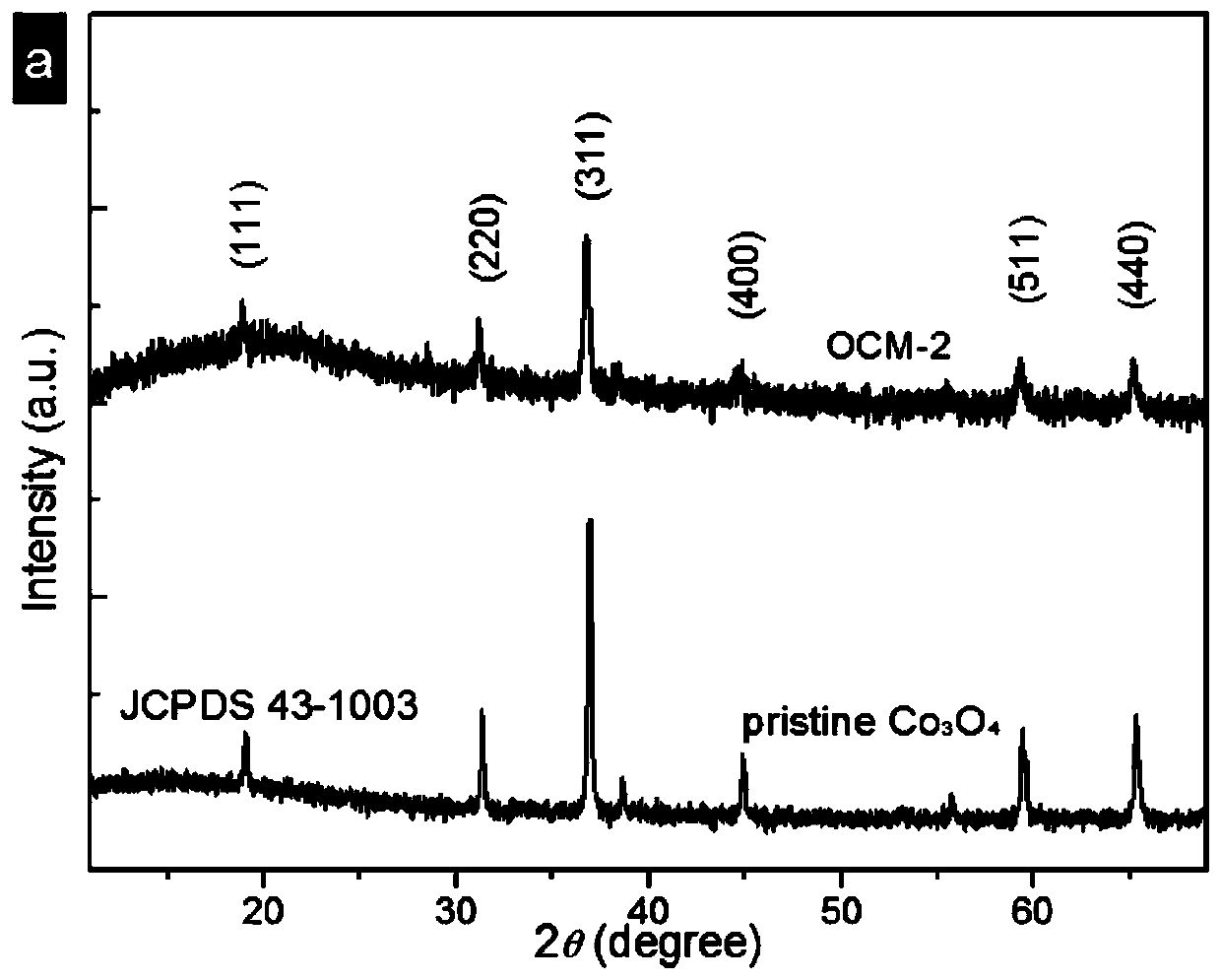

[0031] The invention provides a method for synthesizing a cotton-derived porous carbon electrode material, comprising the following steps: using cotton as a carbon source, and undergoing pre-carbonization treatment to obtain a porous carbon material; then using cobalt nitrate as a cobalt source, using the porous carbon material As a carrier, cobalt oxide particles are grown in situ on the surface of the porous carbon material through hydrothermal reaction to obtain a composite; the composite is carbonized to obtain a cotton-derived porous carbon electrode material. Using the method of in-situ growth, the porous carbon composite material with uniform surface adhesion can be obtained, so that it has better electrical conductivity.

[0032] Further, the pre-carbonization treatment step includes: ultrasonically cleaning the degreased cotton with an aqueous ethanol solution, drying and cutting into small pieces, and then pre-carbonizing to obtain the porous carbon material, which fa...

Embodiment 1

[0044] In this example, a cotton-derived porous carbon electrode material is synthesized according to the following steps:

[0045] (1) Take 5g of absorbent cotton and ultrasonically clean it with a mixed solution of alcohol and ultrapure water for 10 minutes, then dry the absorbent cotton at 100°C, and then cut it into small pieces smaller than 1mm with scissors;

[0046] (2) Place a small piece of absorbent cotton in a tube furnace at 300°C for pre-carbonization for 30 minutes. After cooling to room temperature, the samples were taken out for later use. Several carbonized samples were taken and soaked in 1mol·L -1 in the cobalt nitrate solution;

[0047] (3) After complete infiltration, put the mixed solution in a 100ml autoclave, react at 180°C and keep it warm for 12h, with a heating rate of 2°C·min -1 , for hydrothermal reaction;

[0048] (4) Filter the mixed solution, wash the obtained solid product with ultrapure water three times and dry it, then calcinate it in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com