Lithium-sulfur battery composite cathode active material and its preparation and application

A composite positive electrode and active material technology, applied in lithium batteries, battery electrodes, nanotechnology for materials and surface science, etc., can solve problems such as adsorption, and achieve lower liquid-sulfur ratio, good electronic conductivity and electrocatalytic activity , the effect of increasing the content of active substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

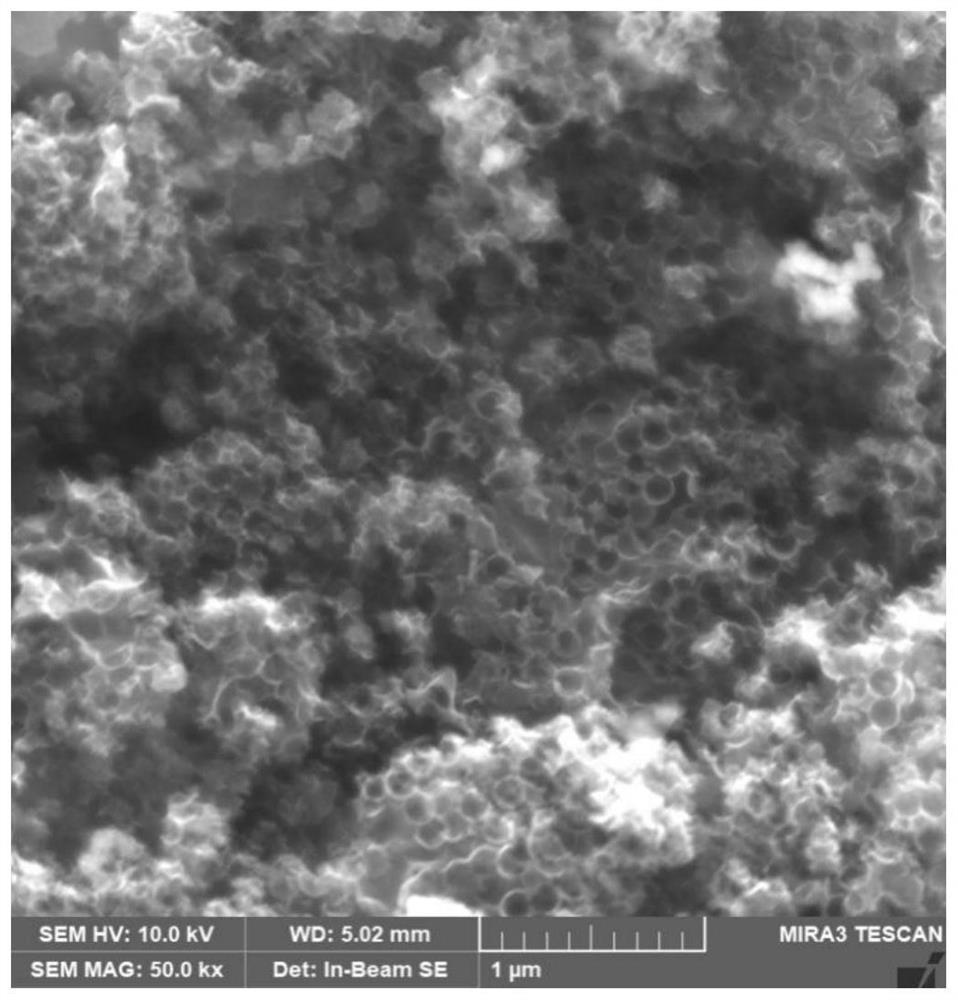

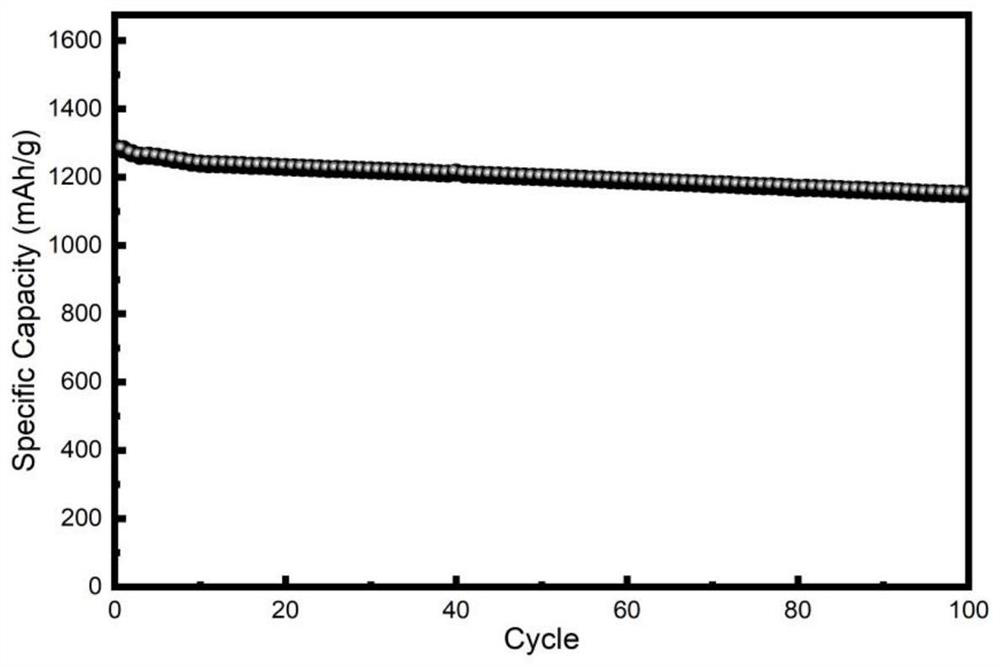

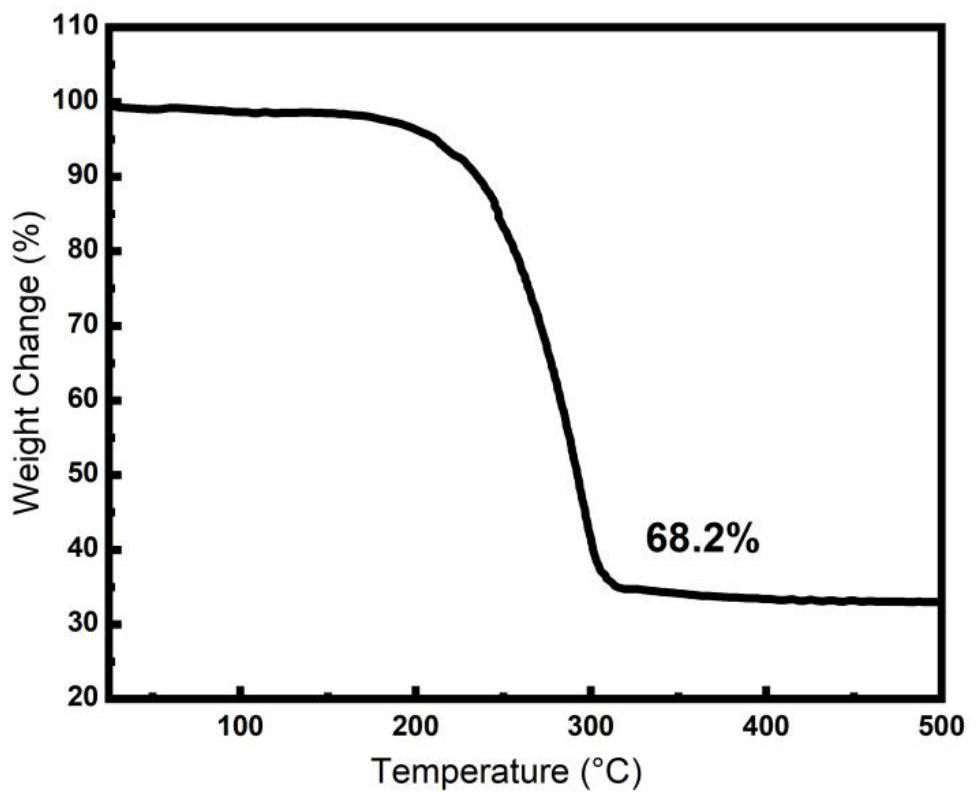

Embodiment 1

[0064] 5 kg of starch, 5 kg of 100nm SiO 2 Add template dispersion liquid and 50 grams of sodium dodecylsulfonate to 10 L of deionized water, stir at 80°C for 5 hours, dry the slurry at 120°C, pulverize the dried slurry, and Carburize in a carbonization furnace at 800°C for three hours in an atmosphere; the carbonized product is washed with 10M sodium hydroxide solution at a temperature of 100°C to remove SiO 2 Template; wash repeatedly with deionized water until the pH of the washing solution is neutral. Then dry the carbon material and mix 2 kg of ammonium metavanadate and 2 kg of selenium powder, ball mill at 300 rpm for 3 hours, then heat-treat the mixed powder at 600 degrees for 2 hours in argon atmosphere pyrolysis furnace , the heating rate is 5°C / min. The porous carbon vanadium selenide composite material can be obtained. The pore volume of the material is 2.24cm 3 / g, the specific surface area is 1468m 2 / g, the porous carbon material pore diameter is mainly conc...

Embodiment 2

[0067] Compared with Example 1, the main difference is that the temperature of the carbon preparation process is changed, specifically:

[0068] 5 kg of starch, 5 kg of 100nm SiO 2 Add template dispersion liquid and 50 grams of sodium dodecylsulfonate to 10 L of deionized water, stir at 80°C for 5 hours, dry the slurry at 120°C, pulverize the dried slurry, and Carburize in a carbonization furnace at 1200°C for three hours in an atmosphere; the carbonized product is washed to remove SiO with 10M sodium hydroxide solution at a temperature of 100°C 2 Template; wash repeatedly with deionized water until the pH of the washing solution is neutral. Then dry the carbon material and mix 2 kg of ammonium metavanadate and 2 kg of selenium powder, ball mill at 300 rpm for 3 hours, then heat-treat the mixed powder at 600 degrees for 2 hours in argon atmosphere pyrolysis furnace , the heating rate is 5°C / min. The porous carbon vanadium selenide composite material can be obtained. The po...

Embodiment 3

[0071] Compared with Example 1, the main difference is that the size of the template in the carbon preparation process is changed, specifically:

[0072] 5 kg of starch, 5 kg of 500nm SiO 2 Add template dispersion liquid and 50 grams of sodium dodecylsulfonate to 10 L of deionized water, stir at 80°C for 5 hours, dry the slurry at 120°C, pulverize the dried slurry, and Carburize in a carbonization furnace at 1200°C for three hours in an atmosphere; the carbonized product is washed to remove SiO with 10M sodium hydroxide solution at a temperature of 100°C 2 Template; wash repeatedly with deionized water until the pH of the washing solution is neutral. Then dry the carbon material and mix 2 kg of ammonium metavanadate and 2 kg of selenium powder, ball mill at 300 rpm for 3 hours, then heat-treat the mixed powder at 600 degrees for 2 hours in argon atmosphere pyrolysis furnace , the heating rate is 5°C / min. The porous carbon vanadium selenide composite material can be obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com