Micron-sized spherical silicon nitride and preparation method thereof

A silicon nitride, micron-scale technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve problems such as high requirements for equipment and sites, difficult industrial production, poor particle sphericity, etc., to meet production needs. , The particle size is uniform and controllable, and the sphericity is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

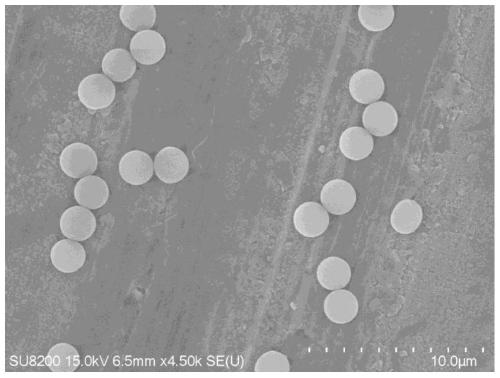

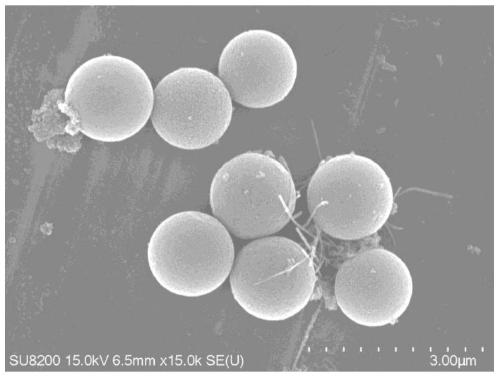

[0034] (1) Mix deionized water, methanol, and concentrated ammonia water according to the volume ratio of 9:9:2, place in a water bath and heat to 40°C and keep the temperature constant, and obtain solution A evenly by magnetic stirring, according to the ratio of 3:2 Weigh phenyltrimethoxysilane and tetraethyl silicate, stir them evenly in a beaker to obtain solution B, add solution B to solution A, stir at a speed of 600r / min for 10min, then stop stirring, stand still After 2 hours, the final solution was collected by centrifugation at a speed of 10000rpm, and dried in an oven at 100°C for 24 hours. The SEM image of the obtained silica spheres is as follows: figure 1 shown.

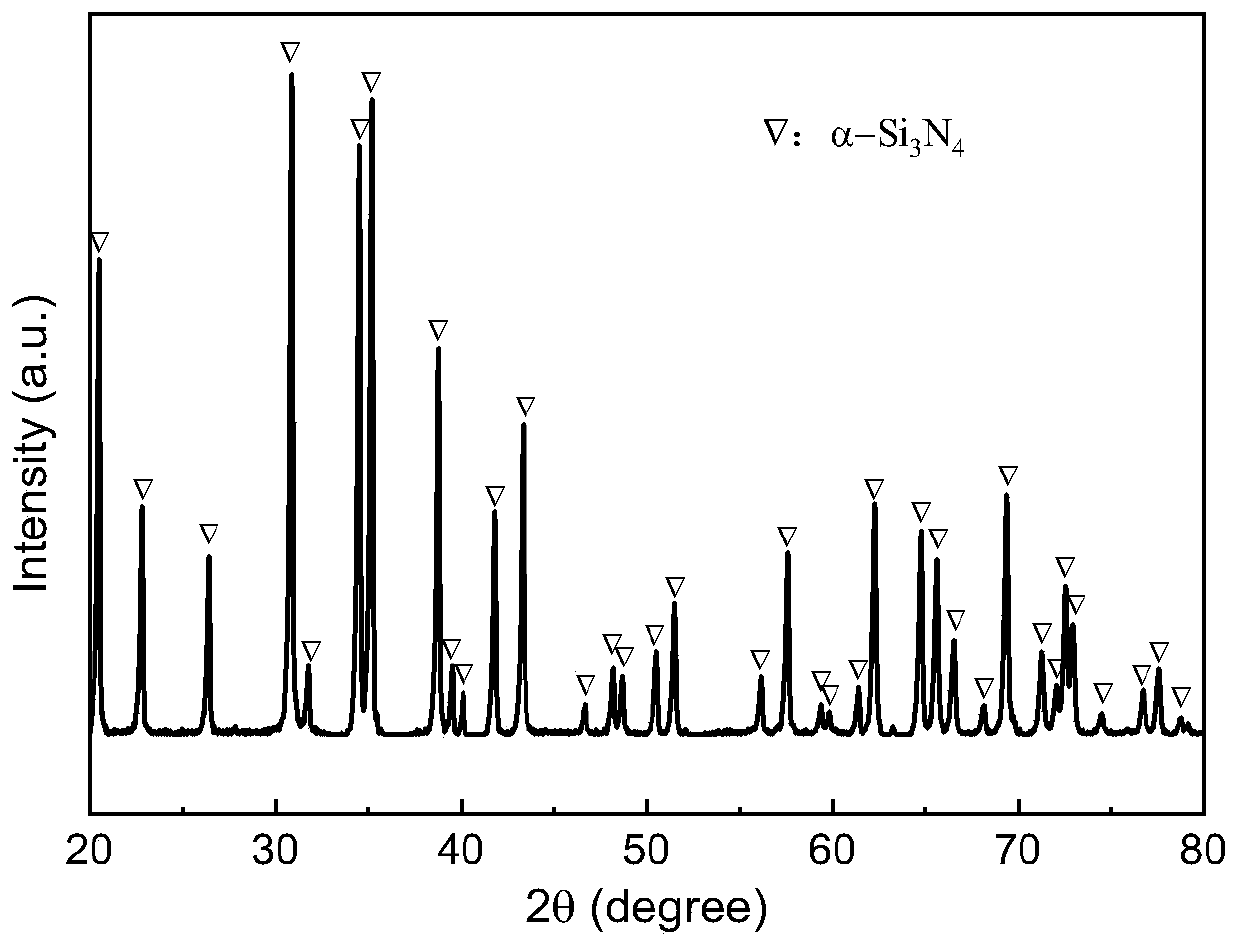

[0035] (2) Place the silicon dioxide powder obtained in step 1 in an alumina crucible, put it into a tube furnace, then carry out two vacuum pumping treatments, and then feed high-purity nitrogen gas. The nitrogen flow rate is set to 300mL / min, and the heating rate is Set at 5°C / min, keep warm at 1475°C...

Embodiment 2

[0041] (1) Mix deionized water, ethanol, and concentrated ammonia water according to the volume ratio of 9:9:2, place in a water bath and heat to 25°C and keep the temperature constant, and obtain solution A evenly by magnetic stirring, according to the ratio of 3:2 Weigh phenyltrimethoxysilane and tetraethyl silicate, stir them evenly in a beaker to obtain solution B, add solution B to solution A, stir at a speed of 600r / min for 10min, then stop stirring, stand still After leaving for 2 hours, the final solution was collected by centrifugation at a rotational speed of 10000 rpm, and dried in an oven at 100° C. for 24 hours to obtain the intermediate silica microspheres.

[0042] (2) Place the silicon dioxide powder obtained in step 1 in an alumina crucible, put it into a tube furnace, then carry out two vacuum pumping treatments, and then feed high-purity nitrogen gas. The nitrogen flow rate is set to 300mL / min, and the heating rate is Set at 5°C / min, keep warm at 1450°C for ...

Embodiment 3

[0045] (1) Mix deionized water, methanol, and concentrated ammonia water according to the volume ratio of 3:15:2, place in a water bath and heat to 40°C and keep the temperature constant, and obtain solution A evenly by magnetic stirring, according to the ratio of 3:2 Weigh phenyltrimethoxysilane and tetraethyl silicate, stir them evenly in a beaker to obtain solution B, add solution B to solution A, stir at a speed of 600r / min for 30min, then stop stirring, stand still After leaving for 2 hours, the final solution was collected by centrifugation at a rotational speed of 10000 rpm, and dried in an oven at 100° C. for 24 hours to obtain the intermediate silica microspheres.

[0046] (2) Place the silicon dioxide powder obtained in step 1 in an alumina crucible, put it into a tube furnace, then carry out two vacuum pumping treatments, and then feed high-purity nitrogen gas. The nitrogen flow rate is set to 300mL / min, and the heating rate is Set at 5°C / min, keep warm at 1475°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com