Water-based inorganic three-proofing coating and preparation method thereof

An inorganic, water-based technology, applied in anti-corrosion coatings, fire-resistant coatings, anti-fouling/underwater coatings, etc., can solve problems such as fire hazards and air pollution, and achieve the effects of poor water resistance, accelerated curing, and good low-temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-3

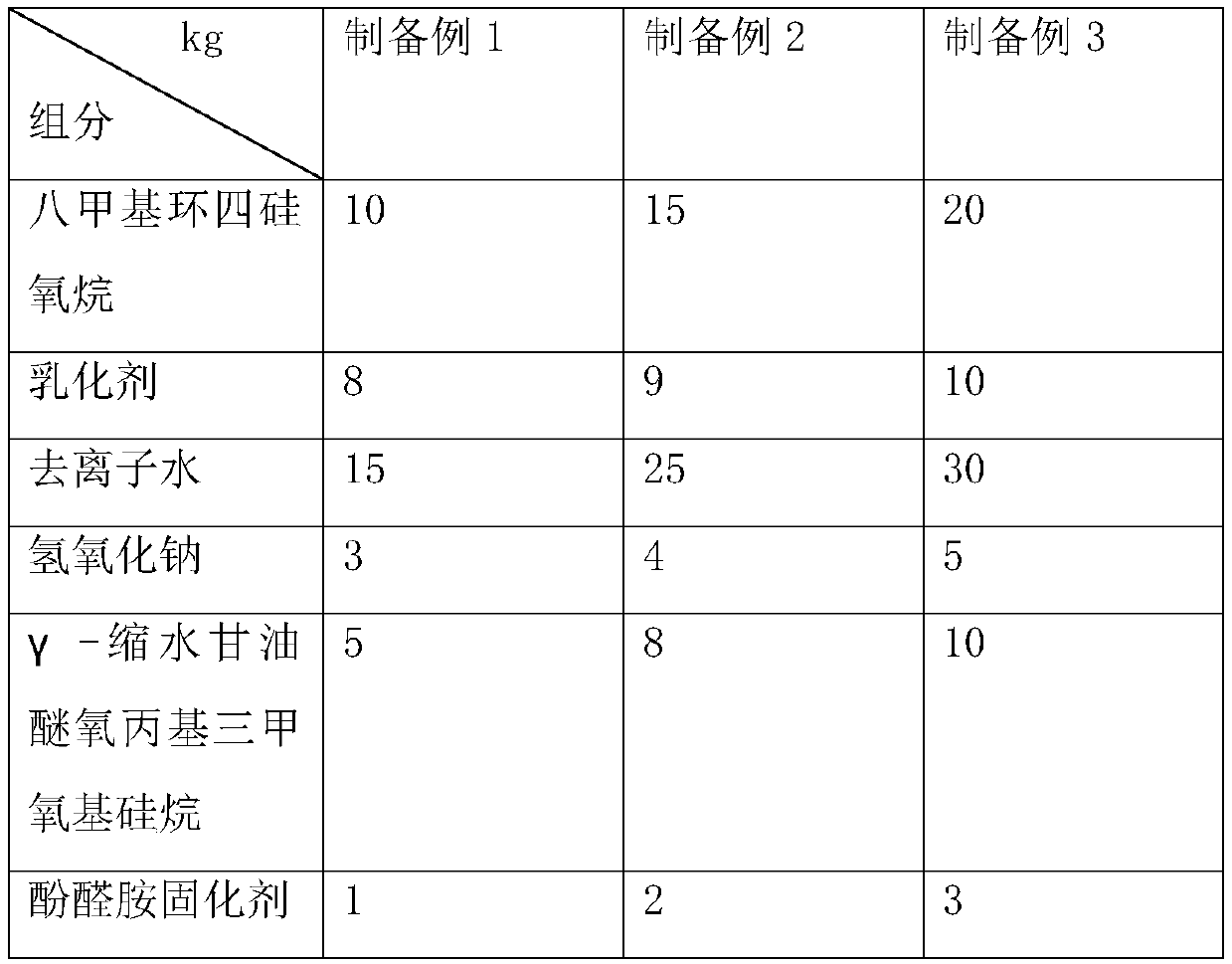

[0044] Octamethylcyclotetrasiloxane in Preparation Example 1-3 was selected from the octamethylcyclotetrasiloxane of model D3 sold by Shandong Xinjie Environmental Protection Technology Co., Ltd., and the phenalkamine curing agent in Preparation Example 1-3 was selected from Shandong Deyuan Epoxy Technology Co., Ltd. DFT-31, γ-glycidyl ether oxypropyl trimethoxysilane was selected from the γ-glycidyl ether oxypropyl silane model AC-66 sold by Fangzhou (Fogang) Chemical Materials Co., Ltd. trimethoxysilane.

preparation example 1

[0045] Preparation Example 1: (1) According to the raw material ratio in Table 1, 10kg octamethylcyclotetrasiloxane and 5kg γ-glycidyl ether oxypropyltrimethoxysilane were mixed uniformly;

[0046] (2) 8kg of emulsifier, 15kg of deionized water, 3kg of sodium hydroxide and 1kg of phenalkamine curing agent are heated to 65°C at a rotational speed of 400r / min, the product of step (1) is added within 1.5h, and the reaction is kept for 9h , sharply cooled to 30°C, neutralized with acetic acid, filtered, and discharged to obtain an anionic silicone emulsion. The emulsifier includes polyoxyethylene octylphenol ether, sodium lignosulfonate and Dodecylbenzenesulfonic acid.

[0047] The raw material ratio of the anionic silicone emulsion in the preparation example 1-3 of table 1

[0048]

preparation example 2

[0049] Preparation Example 2: (1) According to the raw material ratio in Table 1, 15kg octamethylcyclotetrasiloxane and 8kg γ-glycidyl ether oxypropyltrimethoxysilane were mixed uniformly;

[0050] (2) 9kg of emulsifier, 25kg of deionized water, 4kg of sodium hydroxide and 2kg of phenalkamine curing agent were heated to 68°C at a rotating speed of 500r / min, and the product of step (1) was added within 1.3h, and the reaction was incubated for 9h. , sharply cooled to 35°C, neutralized with acetic acid, filtered and discharged to obtain an anionic silicone emulsion. The emulsifier includes polyoxyethylene octylphenol ether, sodium lignosulfonate and Dodecylbenzenesulfonic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com