Tubular pressurizing, oxidizing and ammoniating integrated reaction system for flue gas ammonia desulphurization

A technology of ammonia desulfurization and reaction system, which is applied in the field of reactor technology and environmental engineering, which can solve the problems of low utilization rate of oxidizing wind, large excess air coefficient, and inability to accurately add ammonia to regeneration of absorption liquid, so as to achieve targeted and precise Oxidation and ammoniation, efficient oxidation and ammoniation, small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The boiler design capacity of a chemical enterprise is 2×220t / h. The company built a flue gas ammonia desulfurization device, which adopted two furnaces and one tower, and crystallization process in the tower. The full-load flue gas volume of a single tower is about 25×10 4 Nm3 / h, the sulfur content of the design coal is 0.5%, and the maximum sulfur dioxide content of the flue gas inlet is 1100mg / Nm 3 , the designed outlet sulfur dioxide is required to be less than 35mg, and the nitrogen oxides can be less than 50mg. oxidization and oxidation.

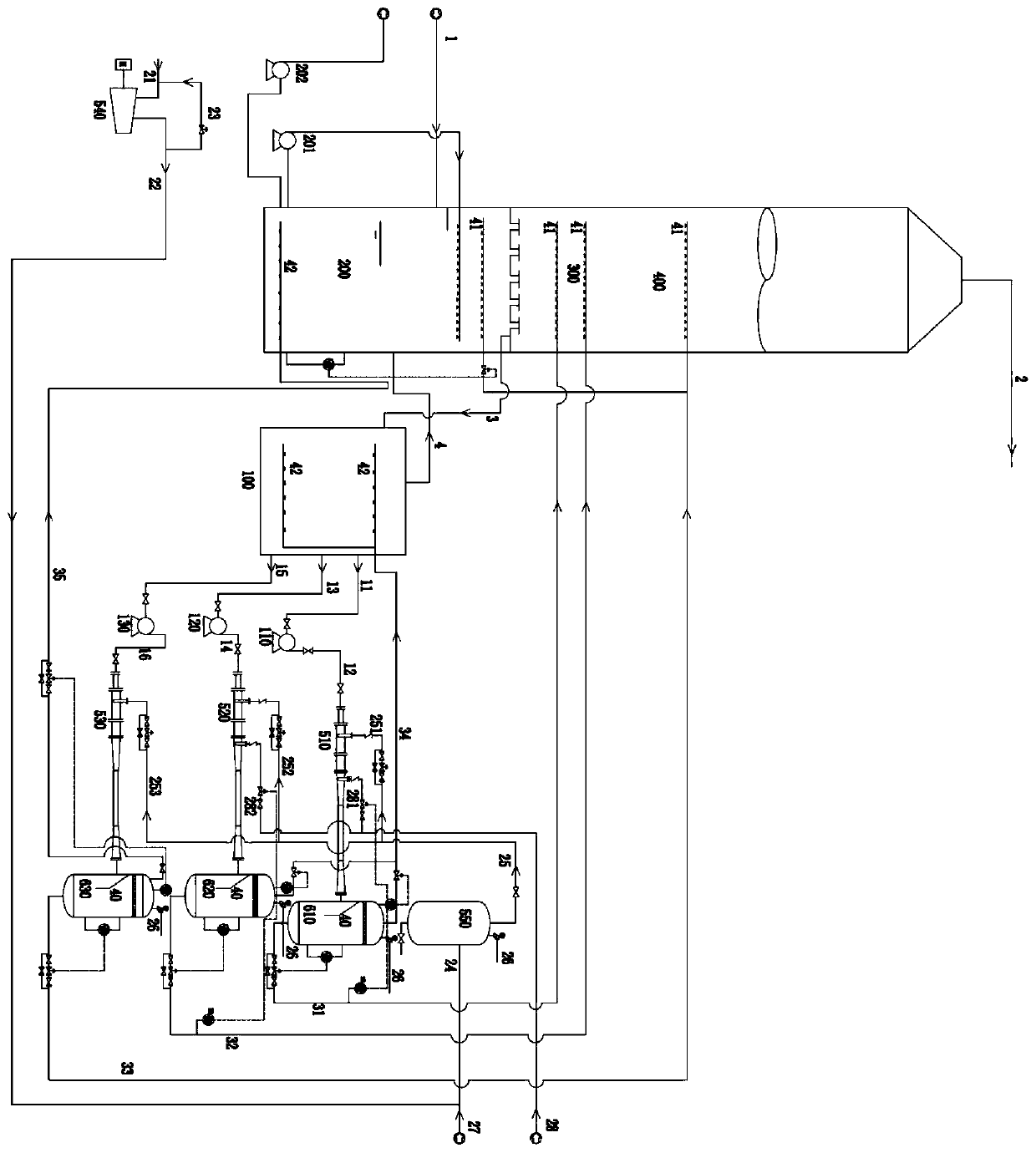

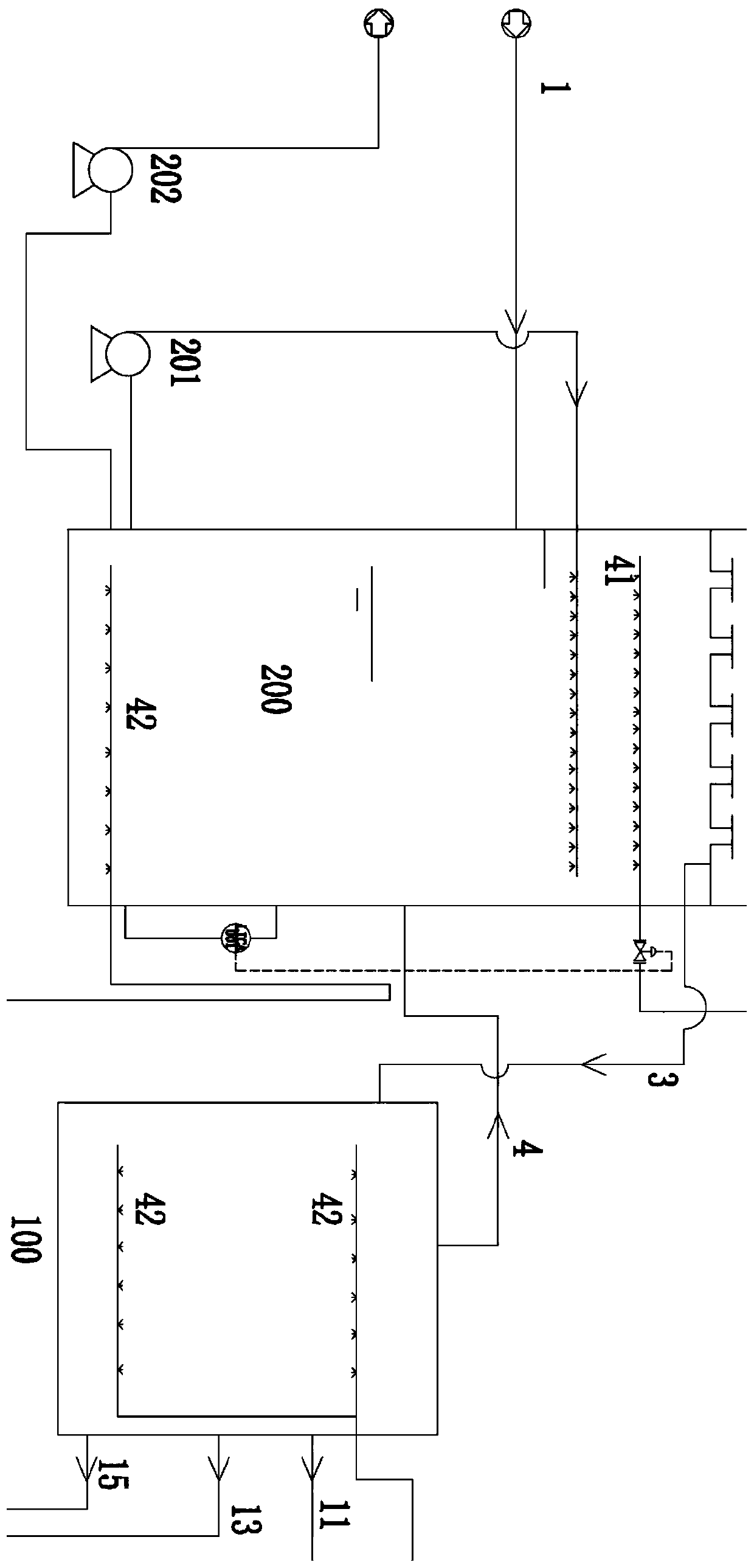

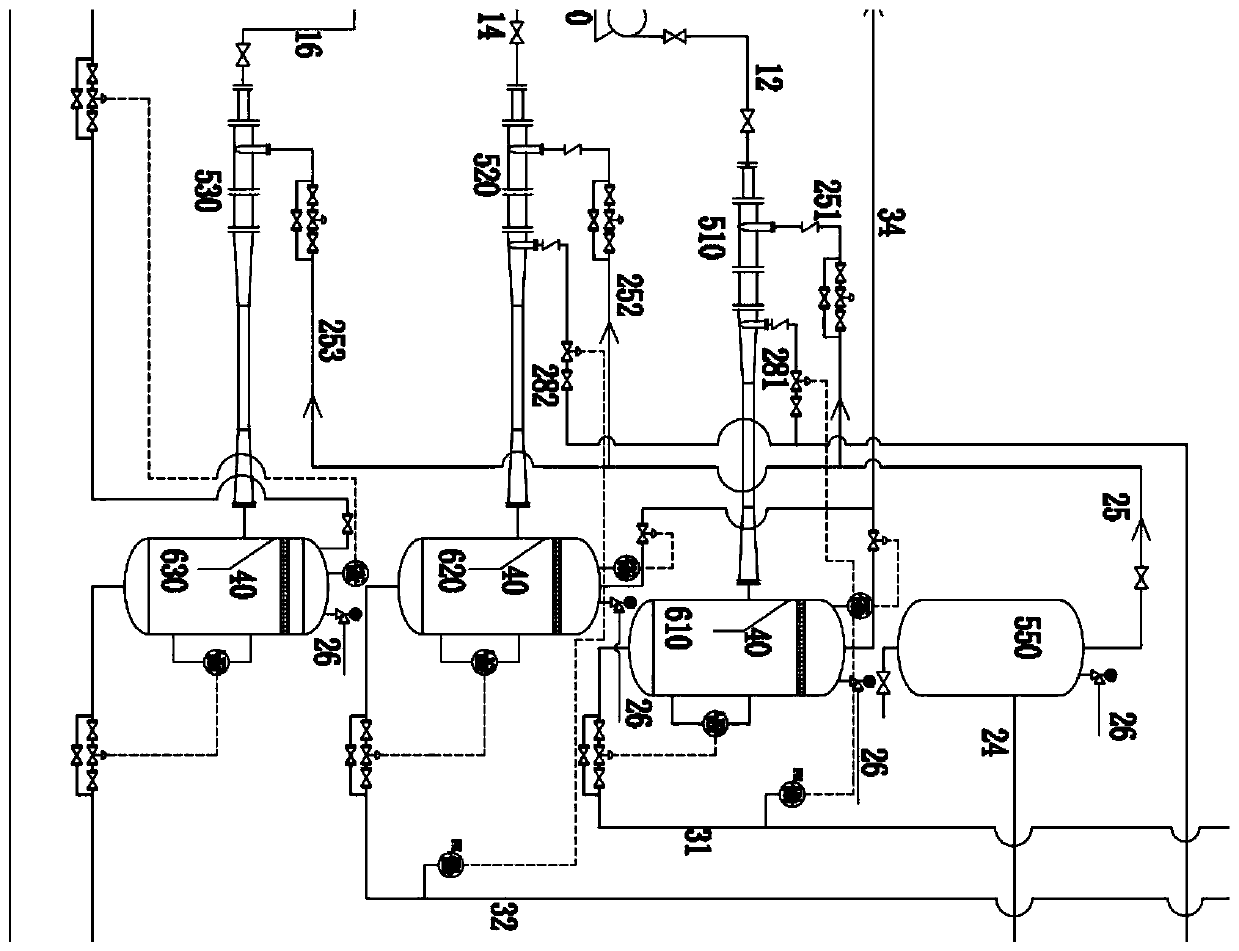

[0041] The overall design of the tubular pressurized oxidative ammonification integrated reaction system for flue gas ammonia desulfurization described in this embodiment is specifically (see Figure 1-Figure 4 ): including a desulfurization tower, an incomplete oxidation solution tank 100, an oxidation-ammonation reaction system and a gas-liquid separation system, the desulfurization tower is connected to the incomplete oxidat...

Embodiment 2

[0076] The boiler design capacity of a chemical enterprise is 4×160t / h. The company has built a flue gas ammonia desulfurization device, which adopts four furnaces and one tower, subsaturated absorption, and adopts a double tower process. External steam evaporation and crystallization process, the single tower full load flue gas volume is about 21×10 4 Nm3 / h, the sulfur content of the designed coal is 0.55%. This process adopts side stirring + oxidation spray gun for oxidation. The actual oxidation rate cannot reach the design value of 98.5% or more, and the actual oxidation rate is between 85-93%. The subsequent evaporation and crystallization materials are decomposed Serious, resulting in low product yield, decomposition of ammonia and sulfur dioxide caused environmental pollution on the site.

[0077] The original incomplete oxidation solution sent to the evaporative crystallization device is oxidized and upgraded according to the Figure 5 As shown, the new tubular pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com