Diaphragm composite material and preparation method thereof

A technology of composite materials and layer materials, which is applied in the field of diaphragm composite materials and its preparation, can solve the problems of difficulty in meeting the high-quality requirements of electronic equipment, insufficient damping performance of silica gel diaphragms, and inability to meet speaker applications, etc., to achieve strong rigidity, Good heat resistance, the effect of increasing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040]A preparation method of the above-mentioned diaphragm composite material, the preparation method includes the following steps: S1: PEN film layer preparation, the specific preparation steps include:

[0041] S1.1: Dry the material PEN (that is, polyethylene naphthalate) at 100-130°C for 2.5-4 hours; then weigh the following materials in parts by mass: 70-80 parts of PEN, 10-15 Nylon 6, 10-15 parts of fiber-type filler, 1-2 parts of silane coupling agent and 0.5-1 part of lubricant; and the weighed materials are added to the mixer and mixed to form a mixture;

[0042] S1.2: Add ethanol to the mixture and stir it, then feed it into the extruder for melt blending and extrusion granulation; the mass-number ratio of the ethanol to the mixture is 1: (4-6);

[0043] S1.3: Dry the particles extruded in step S1.2 and feed them into an injection molding machine for injection molding to obtain a long-chain branched PEN film layer;

Embodiment 1

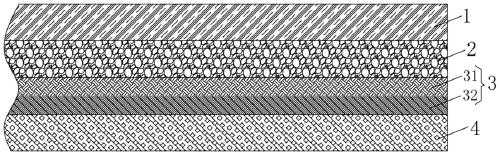

[0060] A diaphragm composite material, comprising a PEN film layer 1, an aluminum-plated film layer 3, an airgel layer 4, and an arrangement between the PEN film layer and the aluminum-plated film layer 3 for bonding the PEN film layer 1 and the elastic adhesive layer 2 of the aluminized film layer 3, the elastic adhesive layer 2 is made of thermoplastic elastomer, specifically mainly made of polyacrylate elastomer or polyurethane elastomer, the elastic adhesive layer 2 The thickness is 12-65 μm, and the setting of the elastic adhesive layer 2 can not only bond the PEN film layer 1 and the aluminized film layer 3 well, but also make the material have a certain toughness, thereby increasing the durability of the product; The aluminized film layer 3 includes a PET film 31 and a metal aluminum layer 32 evaporated on the surface of the PET film 31. The setting of the metal aluminum layer 32 improves the damping performance and electromagnetic shielding performance of the diaphragm ...

Embodiment 2

[0085] This embodiment is basically the same as Embodiment 1, except that the preparation method of the diaphragm composite material provided by this embodiment includes the following steps:

[0086] S1: Preparation of PEN film layer, the specific preparation steps include:

[0087] S1.1: Dry the material PEN (that is, polyethylene naphthalate) at 130°C for 4 hours; then weigh the following materials in parts by mass: 80 parts of PEN, 15 parts of nylon 6, and 15 parts of fiber type Filler, 2 parts of silane coupling agent and 1 part of lubricant; and add the weighed material into the mixer and mix and stir to form a mixture;

[0088] S1.2: Add ethanol to the mixture and stir it, then add it into the extruder for melt blending and extrusion granulation; the ratio of ethanol to the mixture is 1:6 by mass;

[0089] S1.3: Dry the particles extruded in step S1.2 and feed them into an injection molding machine for injection molding to obtain a long-chain branched PEN film layer;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com