Modified concrete brick containing sludge gasification dry distillation slag and preparation method thereof

A technology of sludge gasification and concrete bricks, which is applied to clay preparation devices, chemical instruments and methods, and pyrolysis treatment of sludge, etc., can solve the problems of low utilization rate of urban sludge and lack of green building materials, etc., and achieve reduction The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

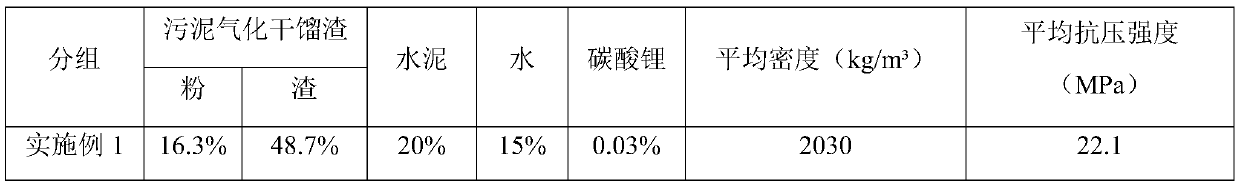

[0026] A modified concrete brick containing sludge gasification and retort slag, the raw materials include: sludge gasification and retort slag 65%, cement 20%, lithium carbonate 0.03%, water 15%, wherein the powder in the sludge gasification and retort slag The slag ratio is 1:3.

[0027] Preparation process: crush the gasified dry distillation slag through a roller crusher, control the coarse particle size to 5-15mm, and then sieve the powder through a 3mm sieve, and the rest is slag; weigh the raw materials according to the formula ratio, mix Stir evenly; pour the mixture into the mold and press to form. The pressing pressure is 20Mpa, and the pressure holding time is 10s. After forming, it is demoulded and placed in a cool place for natural curing.

[0028] The basic mechanical properties of the prepared concrete bricks were tested according to GBT 21144-2007. The ratio and basic mechanical properties of the concrete bricks in this embodiment are shown in Table 1.

[0029...

Embodiment 2

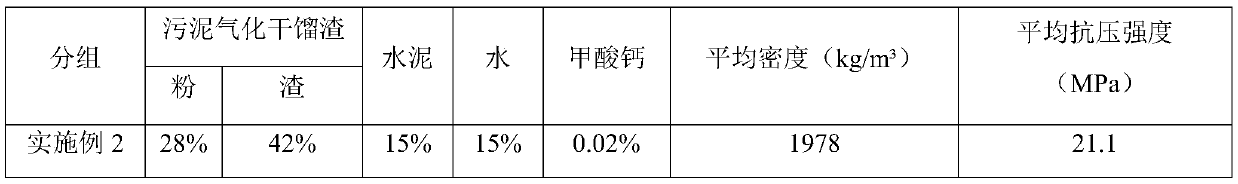

[0033] A modified concrete brick containing sludge gasification and retort slag, raw materials include: sludge gasification and retort slag 70%, cement 15%, calcium formate 0.02%, water 15%, wherein the powder in the sludge gasification and retort slag The slag ratio is 2:3.

[0034] Preparation process: crush the gasified dry distillation slag through a roller crusher, control the coarse particle size to 5-15mm, and then sieve the powder through a 3mm sieve, and the rest is slag. Weigh the raw materials according to the proportion of the formula, mix and stir evenly; pour the mixture into the mold and press to form. The pressing pressure is 30Mpa, and the pressure holding time is 15s. After forming, the mold is demoulded and placed in a cool place for natural curing.

[0035] The basic mechanical properties of the prepared concrete bricks were tested according to GBT 21144-2007. The proportion and basic mechanical properties of the concrete bricks in this embodiment are shown...

Embodiment 3

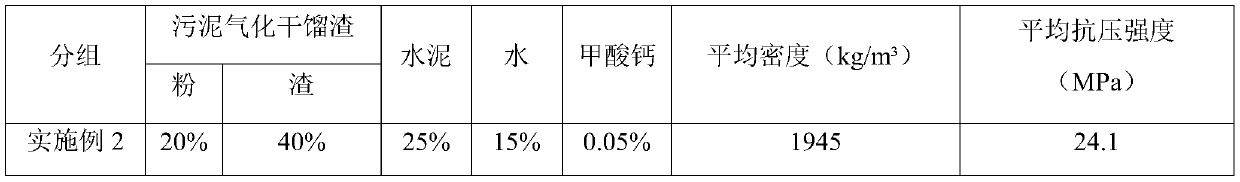

[0040] A modified concrete brick containing sludge gasification and retort slag, the raw materials include: sludge gasification and retort slag 60%, cement 25%, calcium formate 0.05%, water 15%, wherein the powder in the sludge gasification and retort slag The slag ratio is 1:2.

[0041] Preparation process: crush the gasified dry distillation slag through a roller crusher, control the coarse particle size to 5-15mm, and then sieve the powder through a 3mm sieve, and the rest is slag. Weigh the raw materials according to the proportion of the formula, mix and stir evenly; pour the mixture into the mold and press to form, the pressing pressure is 25Mpa, and the holding time is 10s. After forming, the mold is demoulded and placed in a cool place for natural curing.

[0042] The basic mechanical properties of the prepared concrete bricks were tested according to GBT 21144-2007. The proportion and basic mechanical properties of the concrete bricks in this embodiment are shown in T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com