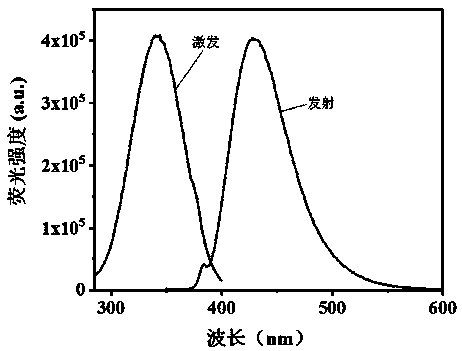

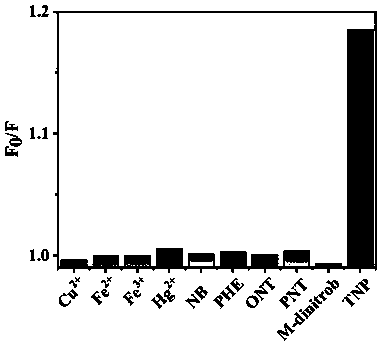

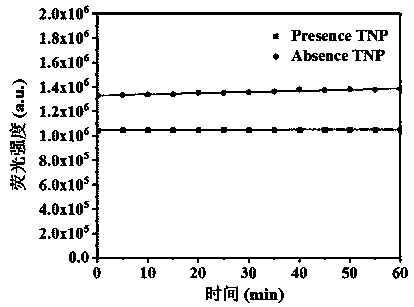

Preparation method of two-dimensional Cu-MOF nanosheet and application of two-dimensional Cu-MOF nanosheet in fluorescence detection of TNP

A fluorescence detection and nanosheet technology, applied in the field of fluorescence detection, can solve the problems of less TNP measurement, expensive use, inconvenient to carry, etc., and achieve the effects of easy storage, accelerated quenching, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take a 50mL beaker, add 40mL of ultrapure water, and dissolve 0.02g of copper chloride and 0.1g of polyvinylpyrrolidone in the ultrapure water. Weigh 0.2 mol of sodium hydroxide and dissolve it in 2.5 mL of ultrapure water to obtain an aqueous solution of sodium hydroxide. Weigh 0.1 mol of ascorbic acid and dissolve it in 2.5 mL of ultrapure water to obtain an aqueous solution of ascorbic acid. Add aqueous sodium hydroxide solution dropwise to the beaker at a rate of 10 μL / s. After the addition is complete, continue stirring for 5 minutes. Continue stirring for 5 minutes and centrifuge to obtain the first product. Wash the first product twice with ethanol solution (analytical pure) to obtain yellow cuprous oxide cubes. Disperse the cuprous oxide cubes in 10 mL of ethanol to obtain a mixed solution. Completely dissolve 0.05 mmol of 2-aminoterephthalic acid in 10 mL of N,N-dimethylformamide to obtain an organic phase solution. Add the mixed solution into the organic phas...

Embodiment 2

[0040] According to the mass ratio of 1:6, take copper chloride and polyvinylpyrrolidone respectively, then take aqueous sodium hydroxide solution and ascorbic acid aqueous solution, the mass ratio of sodium hydroxide contained in copper chloride and aqueous sodium hydroxide solution is 10:1, hydrogen The concentration ratio of sodium oxide aqueous solution to ascorbic acid aqueous solution is 2 to 2.2; completely dissolve copper chloride and polyvinylpyrrolidone in ultrapure water, and then add hydroxide dropwise at a rate of 40 μL / s under magnetic stirring conditions. Sodium aqueous solution, after the addition is complete, continue magnetic stirring for 8 minutes, then, under the condition of magnetic stirring, add ascorbic acid aqueous solution dropwise at a rate of 20 μL / s, after the addition is complete, continue magnetic stirring for 8 minutes, and centrifuge to obtain the first product , ethanol solution (analytically pure) washed the first product three times to obtain...

Embodiment 3

[0042] According to the mass ratio of 1:5.5, take copper chloride and polyvinylpyrrolidone respectively, then take aqueous sodium hydroxide solution and ascorbic acid aqueous solution, the mass ratio of sodium hydroxide contained in copper chloride and aqueous sodium hydroxide solution is 9.25:1, hydrogen The concentration ratio of sodium oxide aqueous solution to ascorbic acid aqueous solution is 2 to 1.6; completely dissolve copper chloride and polyvinylpyrrolidone in ultrapure water, and then add hydroxide dropwise at a rate of 35 μL / s under the condition of magnetic stirring. Sodium aqueous solution, after the addition is complete, continue magnetic stirring for 6.5 minutes, then, under the condition of magnetic stirring, add ascorbic acid aqueous solution dropwise at a rate of 15 μL / s, after the addition is complete, continue magnetic stirring for 7 minutes, and centrifuge to obtain the first product , ethanol solution (analytically pure) washed the first product at least ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com