Preparation of urea-formaldehyde/polybutylene succinate biodegradable polymer slow and controlled release material by reactive extrusion

A polybutylene succinate, biodegradable technology, applied in fertilizer mixtures, solid/semi-solid fertilizers, applications, etc., can solve the problems of difficulty in obtaining UF-based composite materials, low nitrogen release rate, complexity, etc., To achieve the effect of saving manpower, simple and effective preparation process, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

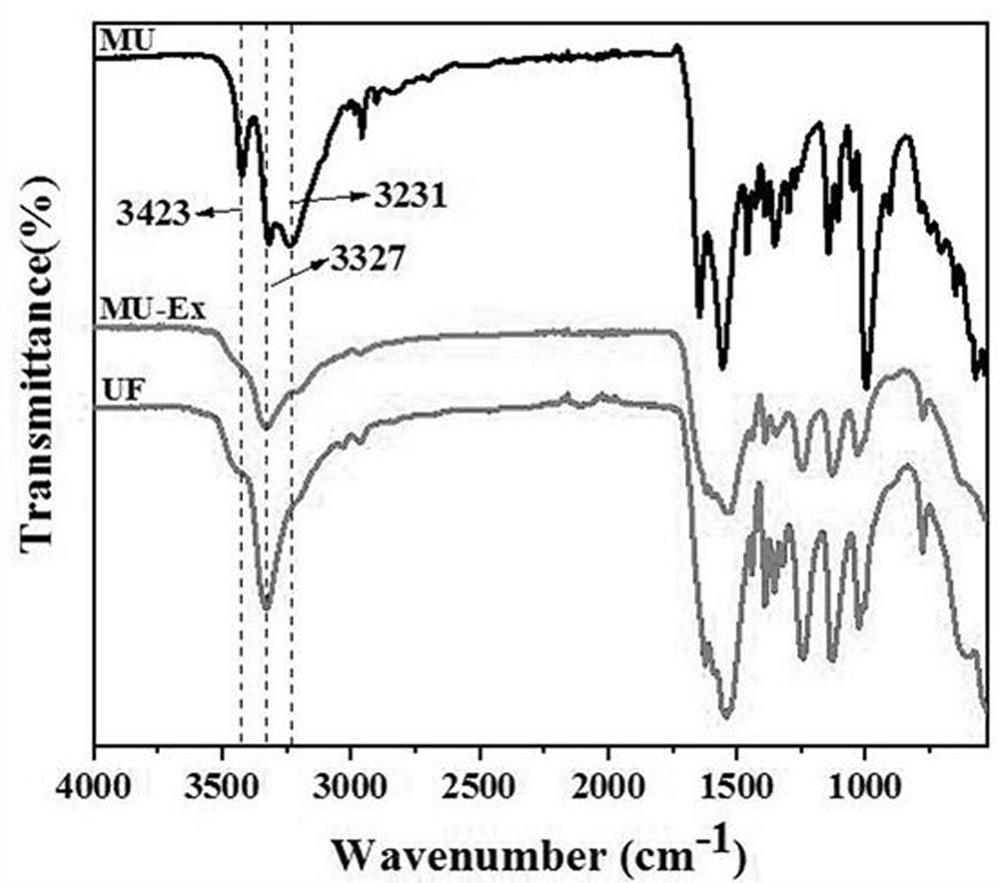

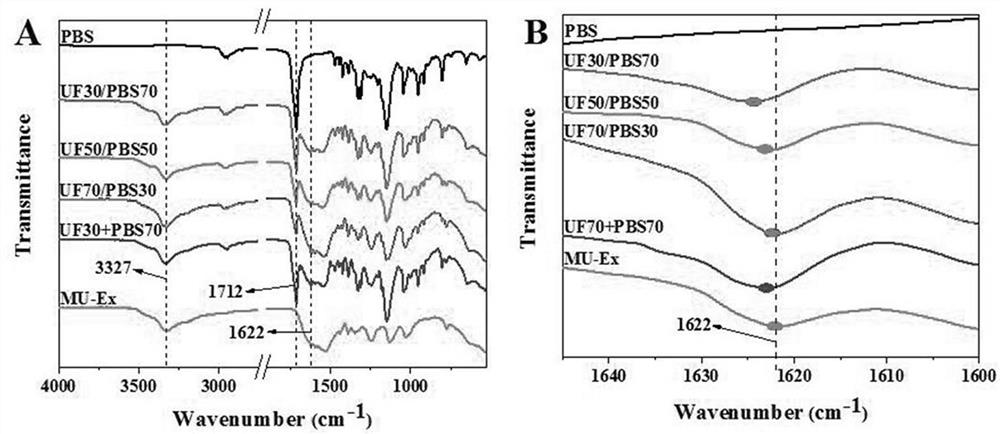

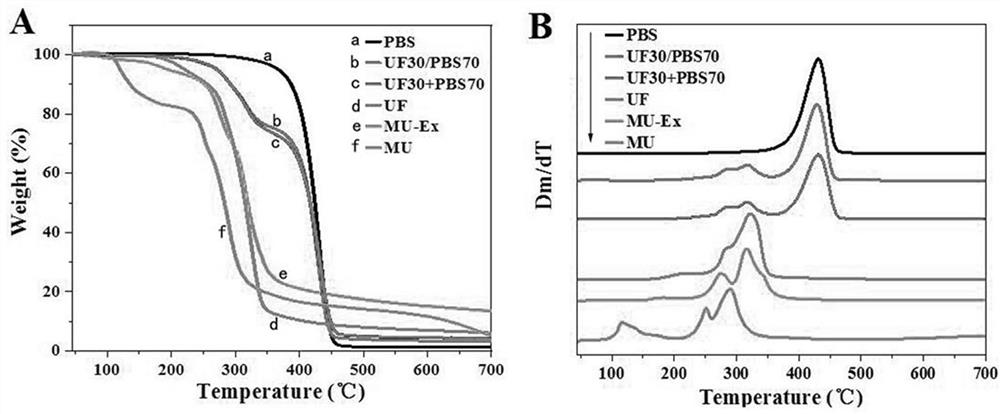

Method used

Image

Examples

Embodiment 1 to 3

[0049] A method for preparing UF / PBS biodegradable polymer sustained and controlled release composite material by reactive extrusion, comprising the following steps

[0050] (1) Preparation of methylol urea: add formaldehyde and urea to the reactor, the molar ratio of the two is 1:1.2, then adjust the solution pH=9, react for a certain period of time at 50°C, then freeze the reaction solution, Finally, filter with suction, dry the solid in a vacuum oven, and then pulverize to 70 mesh to obtain methylol urea powder.

[0051] (2) The raw material PBS is dried and pretreated, and then the pretreated PBS and MU are mixed uniformly in a high-speed mixer according to the mass fractions shown in Table 1, to obtain UF / PBS mixtures with different mass ratios.

[0052] (3) Add the above-mentioned UF / PBS mixtures with different mass ratios to a co-rotating twin-screw extruder (L / D=20, Nanjing Coperion Keya Machinery Co., Ltd., TE-20) to extrude, then get The biodegradation sustained and...

Embodiment 1

[0056] The UF30 / PBS70 biodegradable polymer sustained and controlled release composite material prepared by reactive extrusion of the present invention has a tensile strength of 38.7MPa, an average compressive strength of about 101MPa, and a content of nutrient element nitrogen of 83.97mg / g.

Embodiment 2

[0058] The UF50 / PBS50 biodegradable polymer sustained and controlled release composite material prepared by reactive extrusion of the present invention has a tensile strength of 23.8 MPa, an average compressive strength of about 75 MPa, and a content of nutrient element nitrogen of 139.95 mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com