Polydopamine-cellulose nanofibrils photothermal conversion composite film

A nanofibril, polydopamine technology, applied in the directions of alkali metal compounds, inorganic chemistry, other chemical processes, etc., can solve the problem of low photothermal conversion efficiency, achieve enhanced photothermal conversion efficiency, good water phase stability, source wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

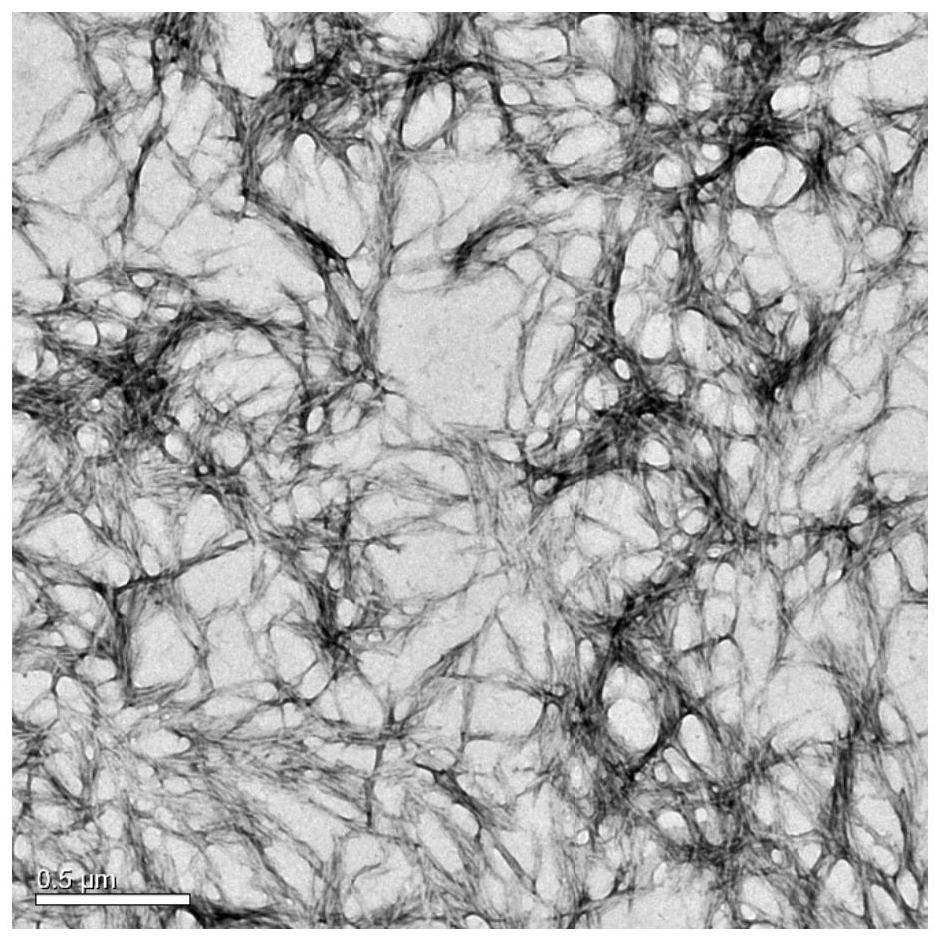

[0033] (1) Mechanically pulverize 5 g of tobacco rods to 20 meshes, and add them into a formic acid solution with a concentration of 80 wt%. The weight ratio of the added tobacco rod to the formic acid solution is 1:50. After reacting for 7 hours at a temperature of 90°C and a stirring speed of 800rpm, the hydrolysis residue was washed to neutrality; then dimethyl sulfoxide was added to the solid for replacement to obtain a suspension of cellulose nanofibrils; After the homogenization treatment, the content of nanofibers in the cellulose suspension is 0.5wt%, the pressure is 100 MPa, and the homogenization times are 10 times; after the treatment, a uniform dispersion of cellulose nanofibrils is obtained. The cellulose nanofibrils in the dispersion liquid are surface esterified cellulose nanofibrils (the degree of substitution of esterification is 0.25), and its TEM morphology photo is as attached figure 1 shown. At the same time, the hydrolyzate is subjected to solid-liquid ...

Embodiment 2

[0036] (1) Mechanically pulverize 5 g of softwood pulp to 20 mesh, and add it into a formic acid solution with a concentration of 90 wt%. The weight ratio of added wood pulp to formic acid solution is 1:25. After reacting for 6 hours at a temperature of 95°C and a stirring speed of 600rpm, the hydrolysis residue was washed to neutrality; then dimethyl sulfoxide was added to the solid for replacement to obtain a suspension of cellulose nanofibrils; After the homogenization treatment, the content of nanofibers in the cellulose suspension is 0.6 wt%, the pressure is 200 MPa, and the homogenization times are 6 times; after the treatment, a uniform dispersion of cellulose nanofibrils is obtained. The cellulose nanofibrils in the dispersion liquid are surface esterified cellulose nanofibrils, and the degree of substitution of esterification is 0.31; at the same time, the hydrolyzate is subjected to solid-liquid separation, and the separated liquid is recovered by vacuum distillation...

Embodiment 3

[0040] (1) Mechanically pulverize 5 g of hardwood pulp to 20 mesh, and add it into a formic acid solution with a concentration of 98 wt%. The weight ratio of added wood pulp to formic acid solution is 1:15. After reacting at a temperature of 96°C and a stirring speed of 200 rpm for 5 hours, the hydrolysis residue was washed to neutrality; then dimethyl sulfoxide was added to the solid for replacement to obtain a suspension of cellulose nanofibrils; After the homogenization treatment, the content of nanofibers in the cellulose suspension is 1 wt%, the pressure is 200 MPa, and the homogenization times are 8 times; after the treatment, a uniform dispersion of cellulose nanofibrils is obtained. The cellulose nanofibrils in the dispersion are surface-esterified cellulose nanofibrils, and the degree of substitution of esterification is 0.37; at the same time, the hydrolyzate is subjected to solid-liquid separation, and the separated liquid is recovered by vacuum distillation Formic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com