A kind of preparation method of high-purity large particle size silica sol

A silica sol, large particle size technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of small silica sol particle size, difficult to control particle size, large dispersion, etc., to achieve large particle size, The effect of short synthesis cycle and fast growth of particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

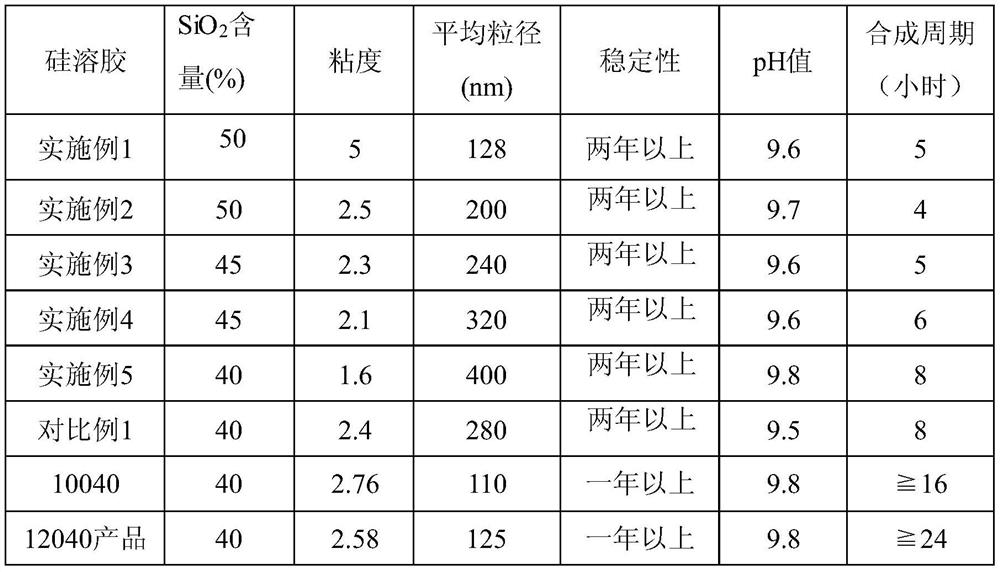

Examples

Embodiment 1

[0032] (1) Preparation of sol crystal grains: add 0.5% polyethylene glycol 2000 whose mass is silica sol solution to the acidic silica sol solution, adjust the pH value to 9.7, heat to 100°C, and obtain sol grains with an average particle diameter of 50nm ;

[0033] (2) Preparation of aluminum-modified silicic acid: at 60°C, add acid to activate the resin, wash the resin until the pH is 3.0, add aluminum nitrate and water glass, and the water glass has an average particle size of 9nm through ion exchange reaction, and the stability Good aluminum-modified silicic acid, wherein the addition of aluminum nitrate is 0.3% of water glass weight.

[0034] (3) Preparation of large particle size silica sol: heat the sol grains in step (1) to 100°C, add the aluminum-modified silicic acid prepared in step (2), the flow rate of the aluminum-modified silicic acid is 14mL / min , add sodium hydroxide at the same time, adjust the pH value to 9.6, synthesize while ultrafiltration, and heat reac...

Embodiment 2

[0037] (1) Preparation of sol grains: add 0.5% polyethylene glycol 6000 with a mass of silica sol solution to the acidic silica sol solution, adjust the pH value to 9.7, heat to 100°C, and obtain sol grains with an average particle size of 100nm ;

[0038] (2) Preparation of aluminum-modified silicic acid: at 60°C, add acid to activate the resin, wash the resin until the pH is 3.0, add sodium metaaluminate and water glass, and the water glass has an average particle size of 8 nm through ion exchange reaction. Aluminum-modified silicic acid with good stability, wherein the addition of sodium metaaluminate is 0.3% of water glass weight.

[0039] (3) Preparation of large particle size silica sol: heat the sol grains in step (1) to 100°C, add aluminum-modified silicic acid in step (2), the flow rate of aluminum-modified silicic acid is 12mL / min, and simultaneously Add sodium hydroxide, adjust the pH value to 9.5, synthesize while ultrafiltration, and heat reaction at 100°C for 4 ...

Embodiment 3

[0042] (1) Preparation of sol grains: Add polyethylene glycol 6000 with a mass of 1% of the mass of the silica sol solution to the acidic silica sol solution, adjust the pH value to 9.5, heat and boil, and obtain sol grains with an average particle size of 150 nm;

[0043] (2) Preparation of aluminum-modified silicic acid: at 60°C, add acid to activate the resin, wash the resin until the pH is 4.0, add sodium metaaluminate and water glass, and the water glass undergoes ion exchange reaction to obtain an average particle size of 10nm. Aluminum-modified silicic acid with good stability, wherein the addition of sodium metaaluminate is 0.5% of water glass weight;

[0044](3) Preparation of large particle size silica sol: the sol matrix of step (1) is boiled, and aluminum-modified silicic acid is added in step (2), and sodium hydroxide is added at the same time to adjust the pH value to 9.5, and the silicic acid The flow rate is 10mL / min, synthesized while ultrafiltration, and heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com