A kind of preparation method of highly dispersed ultrafine neodymium oxide

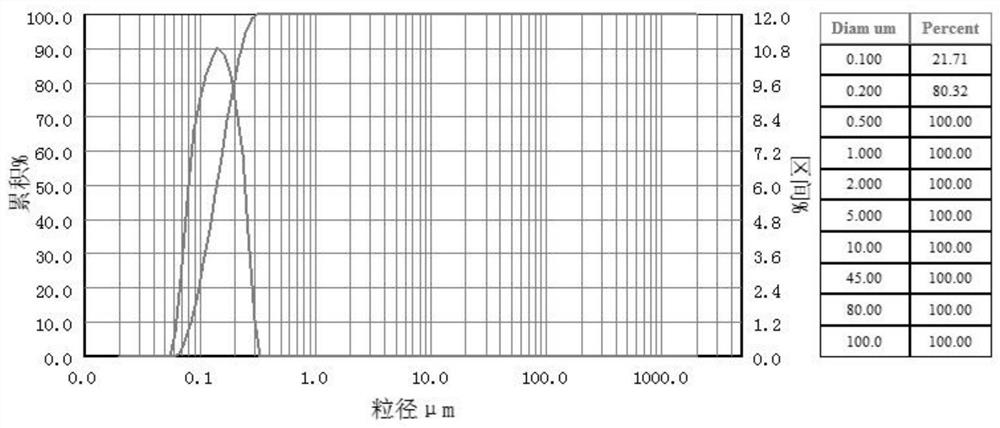

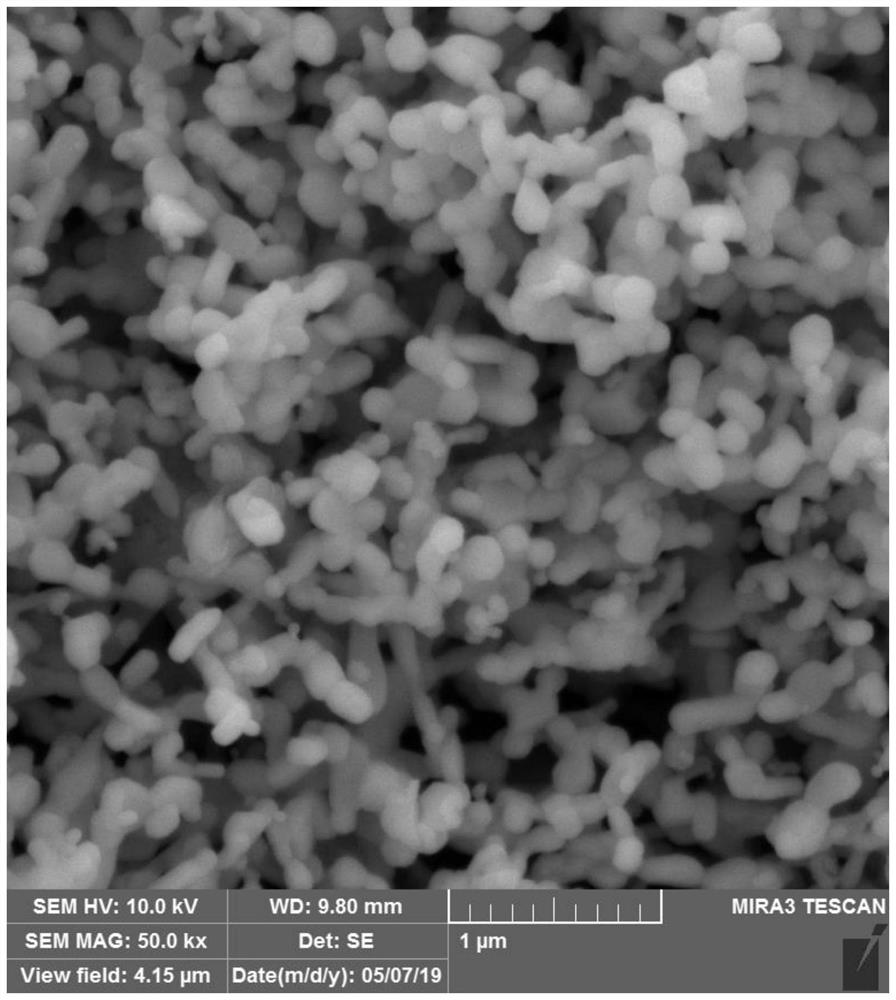

A high-dispersity, neodymium oxide technology, applied in the preparation/processing of rare earth metal compounds, lanthanide oxides/hydroxides, rare earth metal oxides/hydroxides, etc., can solve the problem of uneven particle size distribution, oxidation The problems of large particle size of neodymium and low product purity can achieve the effect of good product particle size and dispersibility, good particle size and dispersibility, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of highly dispersed ultrafine neodymium oxide, comprising the following steps:

[0035] 1. Mixing ingredients: mix ingredients of praseodymium-neodymium enrichment, nitric acid, and water, and remove insoluble impurities through solid-liquid separation to obtain praseodymium-neodymium enrichment material liquid, the concentration of rare earth in the material liquid is 0.1-2.3mol / L;

[0036] 2. Ultrasonic Fractional Distillation Extraction: In the ultrasonic extraction equipment, add praseodymium-neodymium enriched material liquid, extract liquid, lotion, the volume ratio of the three material ingredients is 1:0.5-5.0:0.1-2.0, and the operating conditions are ultrasonic frequency 80kHz, the intensity of ultrasonic action is 20.0W / cm^2, and the operating temperature is 60°C. Ultrasonic fractionation extraction is carried out. The intermediate outlet liquid is the enrichment liquid containing neodymium nitrate, and enters the next step;

[0037] 3. ...

Embodiment 2

[0050] A preparation method of highly dispersed ultrafine neodymium oxide, comprising the following steps:

[0051] 1. Mixing ingredients: mix ingredients of praseodymium-neodymium enrichment, nitric acid, and water, and remove insoluble impurities through solid-liquid separation to obtain praseodymium-neodymium enrichment material liquid, the concentration of rare earth in the material liquid is 0.1-2.3mol / L;

[0052]2. Ultrasonic Fractional Distillation Extraction: In the ultrasonic extraction equipment, add praseodymium-neodymium enriched material liquid, extraction liquid, and washing liquid. The volume ratio of the three material ingredients is 1:0.5-5.0:0.1-2.0, and the operating conditions are ultrasonic frequency 80kHz, ultrasonic intensity 20.0W / cm^2, operating temperature 60°C, conduct ultrasonic fractional distillation extraction, the intermediate outlet liquid is enriched liquid containing neodymium nitrate, enter the next step;

[0053] 3. Ultrasonic extraction:...

Embodiment 3

[0065] A preparation method of highly dispersed ultrafine neodymium oxide, comprising the following steps:

[0066] 1. Mixing ingredients: mix ingredients of praseodymium-neodymium enrichment, nitric acid, and water, and remove insoluble impurities through solid-liquid separation to obtain praseodymium-neodymium enrichment material liquid, the concentration of rare earth in the material liquid is 0.1-2.3mol / L;

[0067] 2. Ultrasonic Fractional Distillation Extraction: In the ultrasonic extraction equipment, add praseodymium-neodymium enriched material liquid, extraction liquid, and washing liquid. The volume ratio of the three material ingredients is 1:0.5-5.0:0.1-2.0, and the operating conditions are ultrasonic frequency 80kHz, ultrasonic intensity 20.0W / cm^2, operating temperature 60°C, conduct ultrasonic fractional distillation extraction, the intermediate outlet liquid is enriched liquid containing neodymium nitrate, enter the next step;

[0068] 3. Ultrasonic extraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com