Method for manufacturing copper-bearing container steel plate casting blank through precise measuring of copper content in nickel-copper alloy

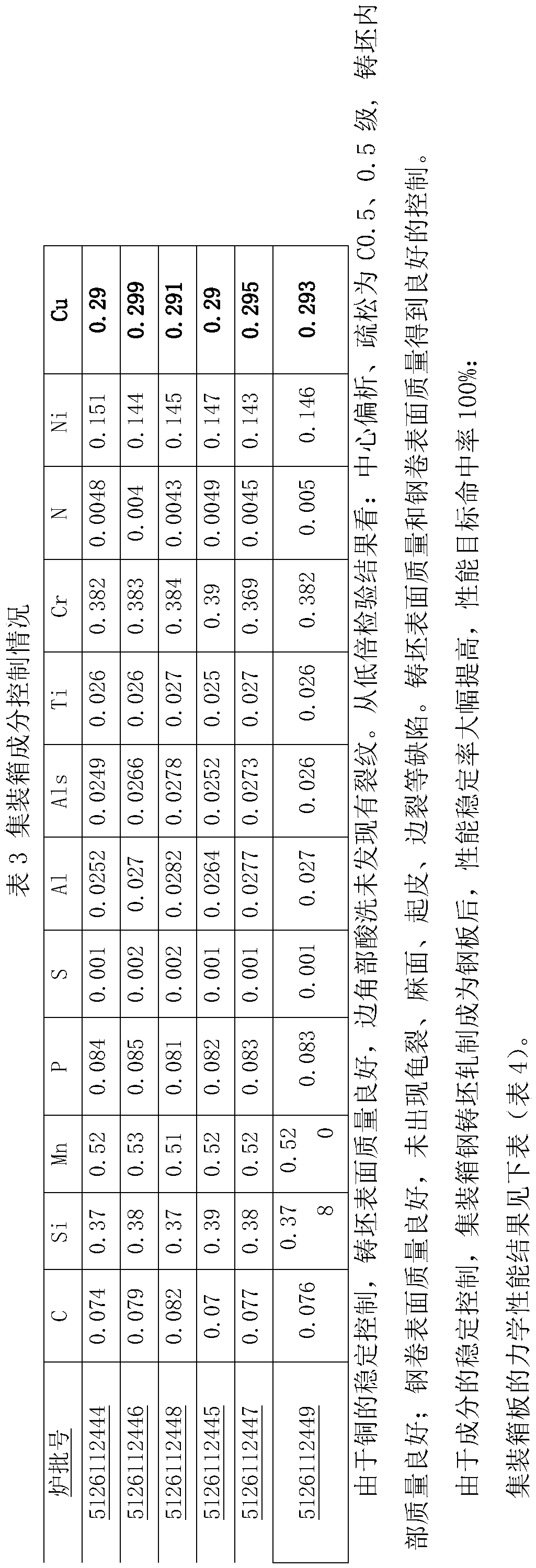

A nickel-copper alloy, copper content technology, applied in the field of metallurgy, can solve problems such as inability to guarantee surface quality, failure to achieve corrosion resistance, etc., to improve the quality of steel-making billets and final rolled products, with good precision and avoidance. The effect of fluctuations in copper content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

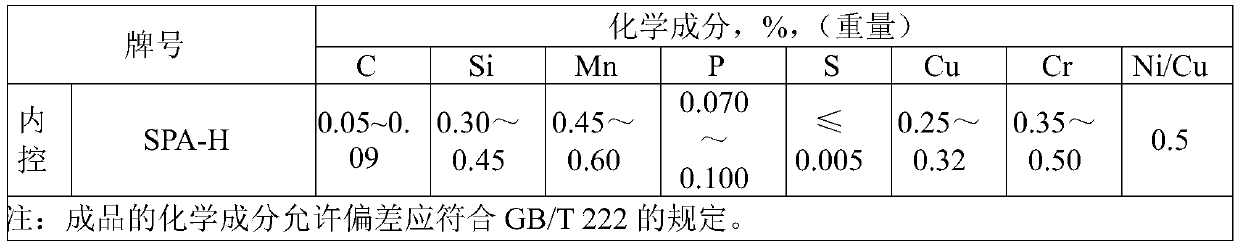

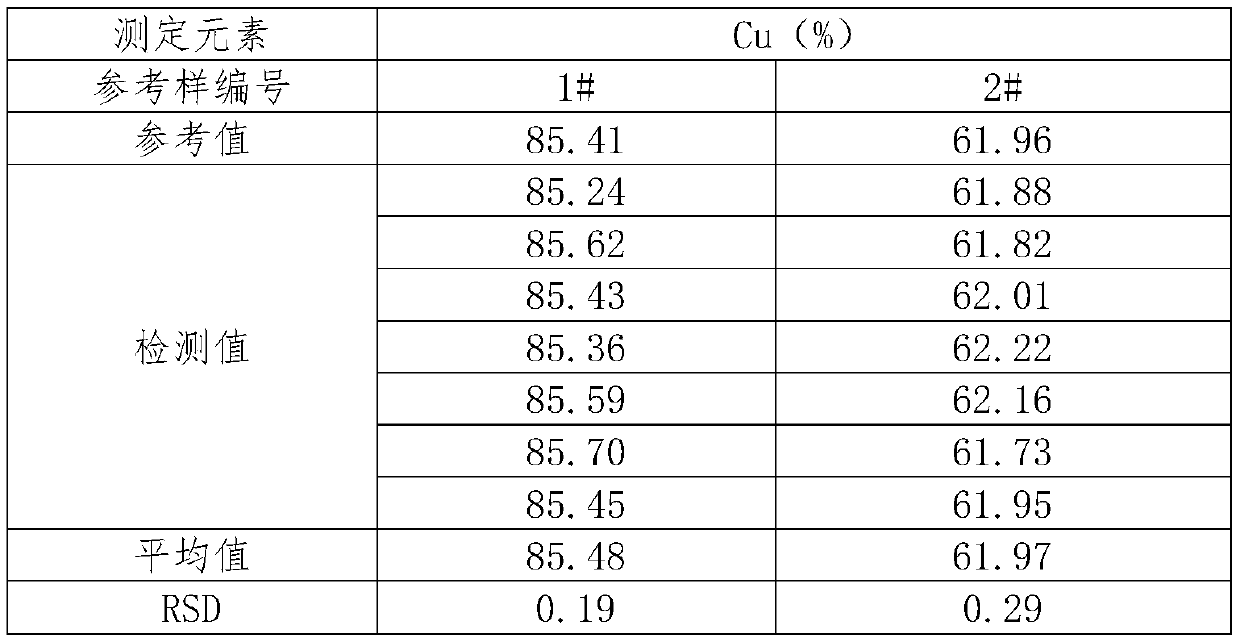

[0077] Embodiment: the method for copper content in the present invention's mensuration nickel-copper alloy adopts following specific steps:

[0078] Use dilute nitric acid to dissolve the sample, ammonia water to separate the iron interfering elements, adjust the pH=5.5 in the filtrate, add excess ethylenediaminetetraacetic acid EDTA solution to complex all the elements that can be complexed, and then add thiourea, 1.10-di The combined masking agent composed of nitrogen phenanthrene (o-phenanthroline) and ascorbic acid selectively decomposes the Cu-EDTA complex, and finally titrates the released EDTA with zinc standard solution, and the copper content can be obtained by calculation.

[0079] (1) Sample dissolution: Weigh 0.5004g of nickel-copper alloy sample into a 200mL beaker, add 20mL (1+2, 1 part of concentrated nitric acid + 2 parts of water) nitric acid, heat until completely dissolved, remove and cool, and constant volume In a 250mL volumetric flask, the sample solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com