Preparation method and application of high-performance nitrogen-doped biomass oxygen reduction catalyst

A biomass and catalyst technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problem of high cost and achieve the effects of simple steps, good oxygen reduction catalytic activity, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

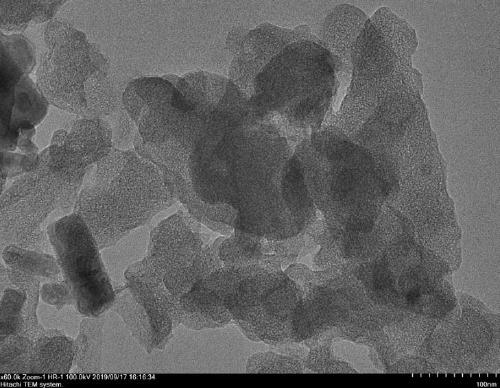

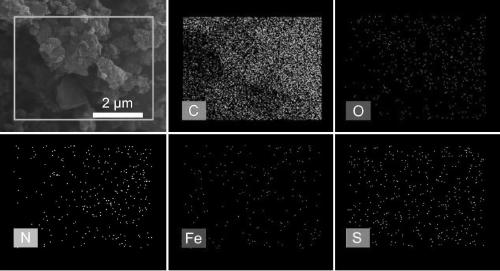

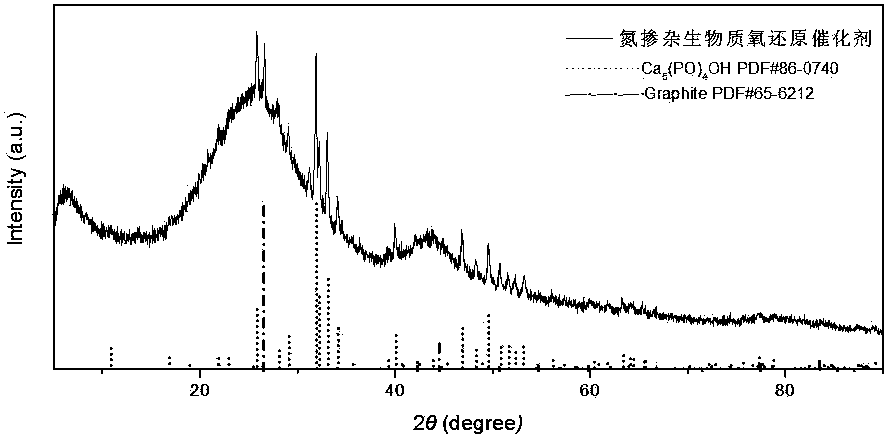

Image

Examples

specific Embodiment 1

[0041] Weigh 5 g of fresh dried black fungus, rinse with deionized water, put them into a polytetrafluoroethylene hydrothermal kettle, make the black fungus account for 1 / 3 of the volume of the hydrothermal kettle, add deionized water to the reaction kettle 2 / 3 of the volume, then put the polytetrafluoroethylene hydrothermal kettle into the stainless steel high-pressure digestion tank and pre-tighten it. Put the stainless steel high-pressure digestion tank into a heating oven, raise the temperature to 180 °C, keep it for 24 h, and then lower it to room temperature. Take out the black fungus biomass carbon black in the polytetrafluoroethylene hydrothermal kettle, use the Buchner funnel to wash it, and wash it with deionized water and absolute ethanol for more than 3 times until the filtrate is colorless. Collect the dried black fungus biomass carbon black after washing, put it in an oven, and dry it at 50 °C for 12 h. Finally, put the biomass carbon black into a mortar and grin...

specific Embodiment 2

[0048] In this example, the nitrogen source in Example 1 was replaced with ammonia water and urea for experimentation.

[0049] The biomass carbonization precursor was prepared according to the method in Example 1.

[0050] The biomass carbonized precursor sample doped with nitrogen and pore-forming agent was transferred to a porcelain boat and put into a tube furnace for calcination. The former porcelain boat loaded with melamine was not placed during calcination. The calcination temperature was kept the same as that in Example 1, and after calcination, the "black fungus precursor + ammonia + urea" oxygen reduction catalyst was obtained.

[0051] The rotating disk electrode half-cell test was carried out on the "black fungus precursor + ammonia + urea" oxygen reduction catalyst, and the test method was consistent with that in Example 1.

[0052] Such as Figure 4 and Figure 5 As shown, the biomass catalyst provided by this specific example has an oxygen reduction polariza...

specific Embodiment 3

[0060] In this example, different calcination temperatures were used to synthesize nitrogen-doped biomass oxygen reduction catalysts. The calcination temperatures were adjusted to 800°C, 900°C, and 950°C, respectively.

[0061] The biomass carbonization precursor was prepared according to the method in Example 1.

[0062]The biomass carbonized precursor sample doped with nitrogen and pore-forming agent was transferred to three porcelain boats of the same size, and placed in a tube furnace for calcination. During the calcination process, a porcelain boat containing 1.5 g of melamine was placed in front of the sample porcelain boat, and the inside of the quartz tube was filled with flowing inert gas. Preferably, the inert gas uses nitrogen (N 2 ). The heating rate of the tube furnace was set at 5°C / min, the calcination temperatures of the three samples corresponding to the tube furnace were set at 700°C, 800°C, and 950°C, and the calcination time was set at 2 h. After the cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Active area | aaaaa | aaaaa |

| Peak power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com