Preparation method of maleic anhydride liquid-phase grafted basalt fiber biological carrier

A technology of basalt fiber and maleic anhydride liquid, applied in the direction of sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., to achieve good chemical and biological stability, easy adhesion, good hydrophilicity and biological phase capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

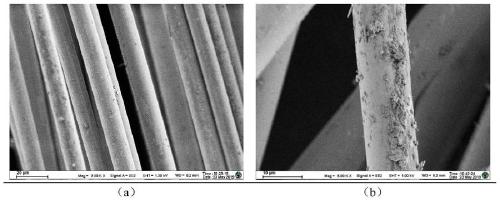

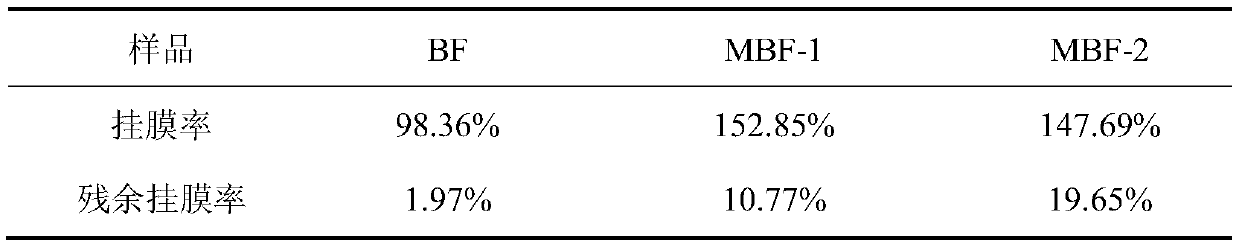

[0022] (1) Weigh 40g of basalt fiber and immerse it in 500ml of acetone solution, put it into an ultrasonic cleaner for cleaning for 2 hours, take it out, wash it repeatedly with deionized water, and put it in an oven at 105°C for drying;

[0023] (2) Prepare a 0.5mol / L NaOH solution, soak the basalt fiber in the NaOH solution, take it out after 2 hours, rinse it with deionized water several times until the pH value of the rinse water is 6.5-7.5, and dry it for later use;

[0024] (3) Prepare a hydrogen peroxide solution with a concentration of 30%, soak the basalt fiber obtained in step (2) in the hydrogen peroxide solution for activation, the soaking time is 2h, and the soaking temperature is 125°C;

[0025] (4) prepare the ethyl acetate solution of maleic anhydride, take a certain amount of maleic anhydride and dissolve it in ethyl acetate, and make the ethyl acetate solution of maleic anhydride whose initial concentration is 0.1mol / L;

[0026] (5) soak the basalt fiber tha...

Embodiment 2

[0028] (1) Weigh 40g of basalt fiber and immerse it in 500ml of acetone solution, put it into an ultrasonic cleaner for cleaning for 2 hours, take it out, wash it repeatedly with deionized water, and put it in an oven at 105°C for drying;

[0029] (2) Prepare a 0.5mol / L NaOH solution, soak the basalt fiber in the NaOH solution, take it out after 2 hours, rinse it with deionized water several times until the pH value of the rinse water is 6.5-7.5, and dry it for later use;

[0030] (3) Prepare a hydrogen peroxide solution with a concentration of 30%, soak the basalt fiber obtained in step (2) in the hydrogen peroxide solution for activation, the soaking time is 2h, and the soaking temperature is 125°C;

[0031] (4) prepare the ethyl acetate solution of maleic anhydride, take a certain amount of maleic anhydride and dissolve it in ethyl acetate, and make the ethyl acetate solution of maleic anhydride whose initial concentration is 1mol / L;

[0032] (5) soak the basalt fiber that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com