Method for preparing nanometer flake cobalt phosphide through vapor deposition

A nano-sheet, vapor deposition technology, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of increasing yield, high reaction temperature, long ion diffusion distance, etc., to achieve easy operation and low reaction temperature. , the effect of stable morphology and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

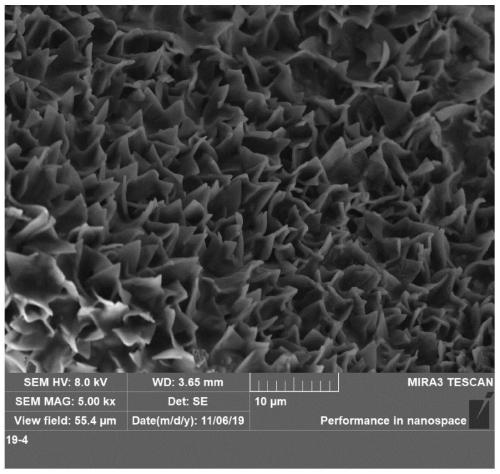

Image

Examples

Embodiment 1

[0022] A method for preparing nano-sheet cobalt phosphide by vapor deposition, comprising the following steps:

[0023] Step (1). Weighing the cobalt source and 2-methylimidazole according to a molar ratio of 1:8, and matching the cobalt source and the solvent with 1 mole of cobalt corresponding to 20 milliliters of solvent to form a solution A;

[0024] The weighed 2-methylimidazole is dissolved in the same volume of solvent to form solution B;

[0025] Pour B into A, stir to form a homogeneous solution, and let it stand at room temperature for 12-24 hours; the cobalt source is cobalt chloride; the solvent is deionized water.

[0026] Step (2). After centrifugal cleaning, vacuum drying for no less than 12 hours, the precursor is obtained; the sheet-like precursor nano-array is prepared by liquid phase deposition at room temperature, and its structure is stable and orderly, which is beneficial to Subsequent synthetic processing.

[0027] Step (3). The above-mentioned precurs...

Embodiment 2

[0030] A method for preparing nano-sheet cobalt phosphide by vapor deposition, comprising the following steps:

[0031] Step (1). Weighing the cobalt source and 2-methylimidazole according to a molar ratio of 1:8, and matching the cobalt source and the solvent with 1 mole of cobalt corresponding to 20 milliliters of solvent to form a solution A;

[0032] The weighed 2-methylimidazole is dissolved in the same volume of solvent to form solution B;

[0033] Pour B into A, stir to form a homogeneous solution, and let it stand at room temperature for 12-24h; the cobalt source is cobalt acetate; the solvent is methanol.

[0034] Step (2). After centrifugal cleaning, vacuum drying for no less than 12 hours, the precursor is obtained; the sheet-like precursor nano-array is prepared by liquid phase deposition at room temperature, and its structure is stable and orderly, which is beneficial to Subsequent synthetic processing.

[0035] Step (3). The above-mentioned precursor and the ph...

Embodiment 3

[0038] A method for preparing nano-sheet cobalt phosphide by vapor deposition, comprising the following steps:

[0039] Step (1). Weighing the cobalt source and 2-methylimidazole according to a molar ratio of 1:8, and matching the cobalt source and the solvent with 1 mole of cobalt corresponding to 20 milliliters of solvent to form a solution A;

[0040] The weighed 2-methylimidazole is dissolved in the same volume of solvent to form solution B;

[0041] Pour B into A, stir to form a homogeneous solution, and let it stand at room temperature for 12-24h; the cobalt source is cobalt nitrate; the solvent is deionized water.

[0042] Step (2). After centrifugal cleaning, vacuum drying for no less than 12 hours, the precursor is obtained; the sheet-like precursor nano-array is prepared by liquid phase deposition at room temperature, and its structure is stable and orderly, which is beneficial to Subsequent synthetic processing.

[0043] Step (3). The above-mentioned precursor and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com