Surface anticoagulation modification method of hemodialyzer and application of hemodialyzer

A technology of hemodialysis and modification methods, which is applied in dialysis systems, suction devices, and drug devices, etc., can solve the problems of long time consumption and high energy consumption, and achieve the effects of good load, simple process flow, and good anticoagulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

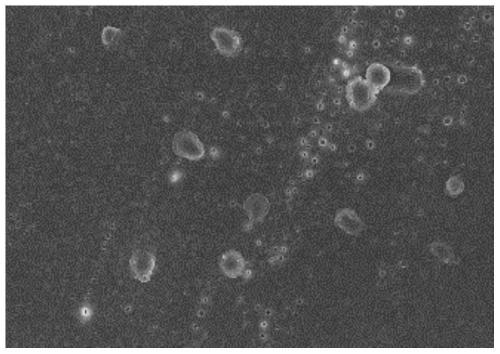

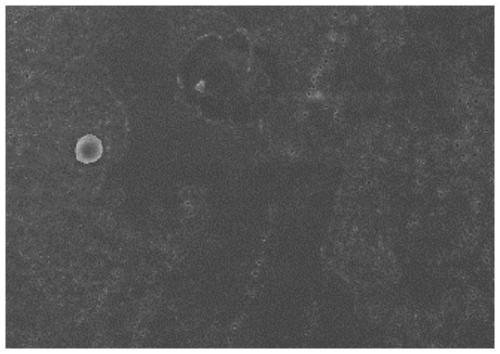

Image

Examples

preparation example Construction

[0044] Wherein, as a more preferred embodiment of the present invention, the synthesis method of the amphiphilic anticoagulant copolymer comprises the following steps:

[0045] Step (1). Add a certain amount of unsaturated double bond sulfonic acid sodium salt monomer, acrylic acid monomer and long carbon chain olefin ester monomer in the first organic solvent of 100 milliliters, stir through nitrogen or argon atmosphere without stirring. Less than 30min to get rid of the oxygen in the reaction solution;

[0046] Step (2). Add a certain amount of initiator, keep stirring in a nitrogen or argon atmosphere, and raise the temperature to 50-100°C, and react for 8-24 hours;

[0047] Step (3). Transfer the solution to an environment of 20-50° C., dry to remove the first organic solvent, and obtain the amphiphilic anticoagulant copolymer.

[0048] In some preferred embodiments, the surface anticoagulation modification method specifically includes: dissolving the amphiphilic anticoag...

Embodiment 1

[0069] Step (1) 6 grams of sodium p-styrene sulfonate, 2 grams of acrylic acid and 8 grams of myristyl methacrylate added in 100 milliliters of ethanol were stirred for 30 minutes at a speed of 600 r / min to eliminate Oxygen in the reaction solution;

[0070] Step (2) Add 0.3 g of dimethyl azobisisocarboxylate, keep stirring in a nitrogen atmosphere, and raise the temperature to 80° C., and react for 16 hours;

[0071] Step (3) transfer the solution to an environment of 50° C., dry and remove ethanol to obtain an amphiphilic anticoagulant copolymer;

[0072] Step (4) configuration volume ratio is 100ml of N, N-dimethylacetamide aqueous solution 100ml, adds the polyoxyethylene-polyoxypropylene copolymer of 0.3 gram, and adds the amphiphilic anticoagulant copolymer of 3 gram synthesis , to obtain a modified solution.

[0073] Step (5) At normal temperature, the modified solution is transported into the dialyzer at a speed of 100 ml / square meter per minute, so that it flows thro...

Embodiment 2

[0079] Step (1) 5 grams of sodium methacrylate, 3 grams of methacrylic acid and 6 grams of octadecyl methacrylate added in 100 milliliters of n-hexane, through an argon atmosphere, at a speed of 400r / min Stir for 40min to get rid of the oxygen in the reaction solution;

[0080] Step (2) Add 0.2 g of azobisisobutyronitrile, keep stirring in an argon atmosphere, and raise the temperature to 50° C., and react for 24 hours;

[0081] Step (3) transfer the solution to an environment of 20°C, dry and remove n-hexane to obtain an amphiphilic anticoagulant copolymer;

[0082] Step (4) Prepare 100 ml of triethyl phosphate aqueous solution with a volume ratio of 15%, add 0.5 g of Span 80, and add 4 g of synthesized amphiphilic anticoagulant copolymer to obtain a modified solution.

[0083] Step (5) At room temperature, the modified solution is transported into the dialyzer at a speed of 200 ml / square meter per minute, so that it flows through the inner surface of the dialyzer membrane f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com