Method for preparing long-chain fatty diacid monobenzyl ester and application thereof

A technology of monobenzyl diacid and chain dibenzyl ester, applied in the field of biopharmaceuticals, can solve the problems of difficulty in purification, difficulty in realizing industrial scale up, complicated post-processing and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

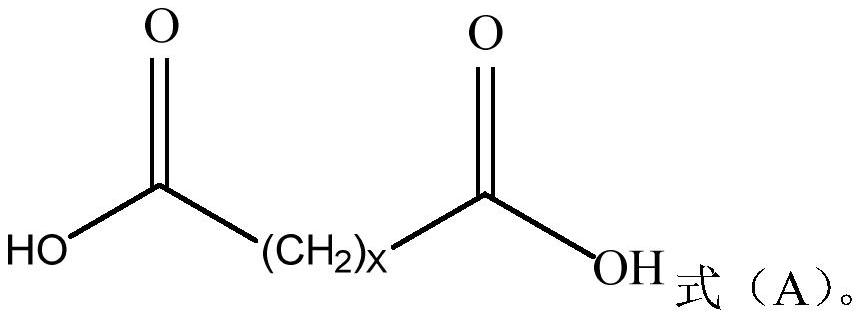

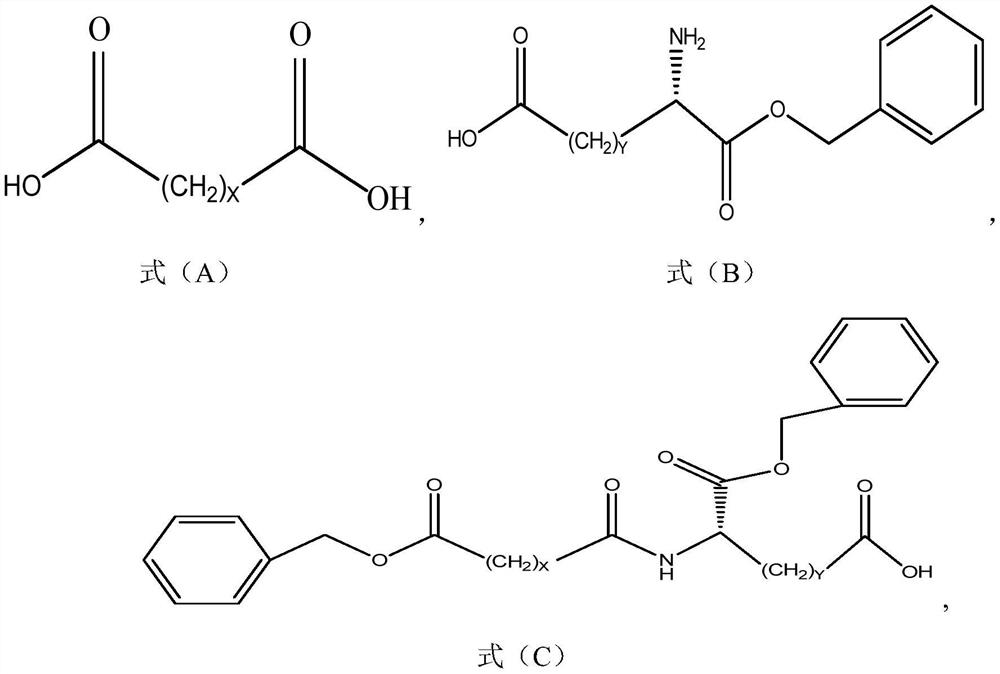

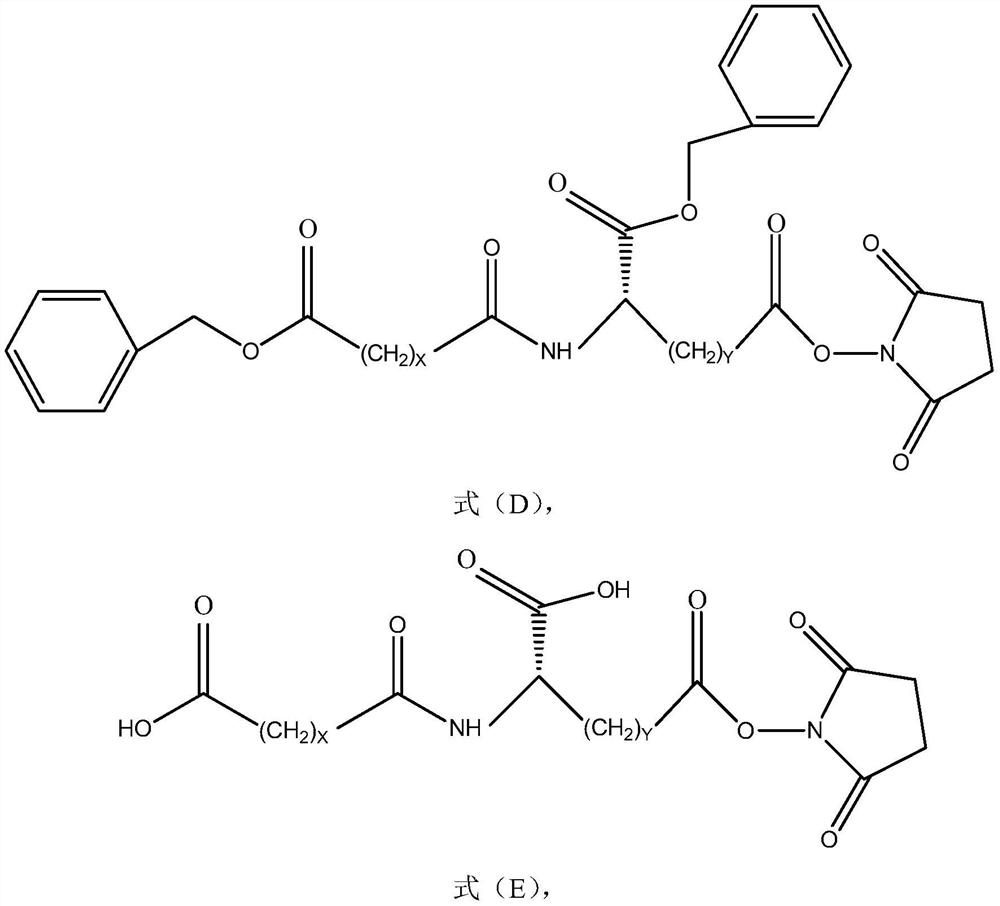

[0053] The method for preparing long-chain fatty diacid monobenzyl ester according to an embodiment of the present invention can be described as follows:

[0054]

[0055] 1-1) Compound A, benzyl alcohol, catalyst a are prepared in solvent b to obtain intermediate A', the reaction is completed, the temperature is lowered to room temperature, then reverse solvent c is added to the reaction system, and the temperature is continued to be about 0°C for crystallization, Filter, rinse the filter cake with reverse solvent c to obtain compound B with a purity of more than 95%, which can be used in the next step after drying.

[0056] 1-2) Compound A', (acid) base d are stirred and reacted in solvent e, and the reaction is completed, (if the reaction is hydrolyzed with acid, acid free and solvent extraction can be skipped) After acid f is free, solvent g is extracted, and the reaction is carried out at room temperature. In the organic phase, reverse solvent h is added for crystalliz...

Embodiment 1

[0087] Example 1 Synthesis of dibenzyl hexadecanedioate

[0088]

[0089] Hexadecanedioic acid (100.0g, 349.4mmol), benzyl alcohol (167.4g, 1547.8mmol), TsOH (6.0g, 34.9mmol) and 1000mL of toluene were added to a 3000mL three-necked flask and placed in a 120°C stirring reaction for 24h, the reaction ended , cooled to room temperature with 0.5M Na 2 CO 3 .aq (35 ml, 17 mmol) was used to wash the reaction system, and the aqueous phase was separated and discarded. 1000ml of n-heptane was added to the organic phase under stirring. With the addition of n-heptane in the system, solids gradually precipitated in the system. After the dropwise addition of n-heptane, the stirring was continued for 0.5 h, and the reaction system was transferred to a low temperature. The crystallization continued in the tank, and the low temperature tank was gradually cooled to -5 °C. When the system was cooled to -5 °C, the system was kept stirring for 1 h to make the system crystallize completely. ...

Embodiment 2

[0092] Synthesis of hexadecanedioic acid monobenzyl ester (a)

[0093]

[0094]Dibenzyl hexadecanedioate (4.7g, 10mmol) and benzyl alcohol (25ml) were added to a 100mL single-necked flask, and after stirring at room temperature to dissolve, under stirring at room temperature, KOH (0.55g, 11mmol) was added dropwise to the reaction system. A solution of benzyl alcohol (10 ml) was added dropwise and stirred at room temperature overnight. Adjust the pH of the reaction system: 1-2 with 1M HCl.aq (25ml), filter, and separate the aqueous phase. At room temperature, n-heptane (40 ml) was added dropwise to the organic phase, and a white solid began to precipitate in the system with the addition of n-heptane. The reaction system was transferred to a low-temperature tank at 0°C, and the temperature was continued to decrease for crystallization. After the system was cooled to 0°C, more solids were precipitated in the reaction flask, and the stirring was continued for 0.5 h. Filter at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com