Basalt protective coating and preparation method thereof

A protective coating and basalt technology, applied in the field of basalt protective coating and its preparation, can solve the problems of poor acid and alkali resistance and weather resistance, short metal substrate protection time, high silica content, etc., and achieve high anti-corrosion performance and excellent resistance to media Penetration performance, fine texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

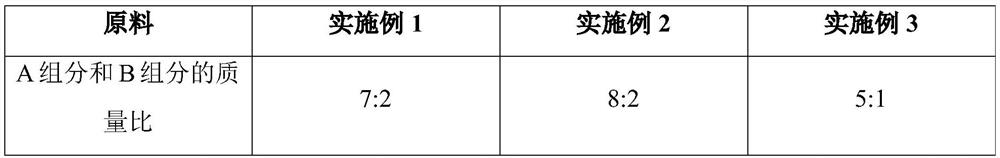

[0056] The preparation method of the basalt protective coating comprises the following steps: uniformly mixing the A component and the B component to obtain the basalt protective coating, wherein, in parts by mass, the ratio of the A component to the B component is shown in Table 1.

[0057] Table 1

[0058]

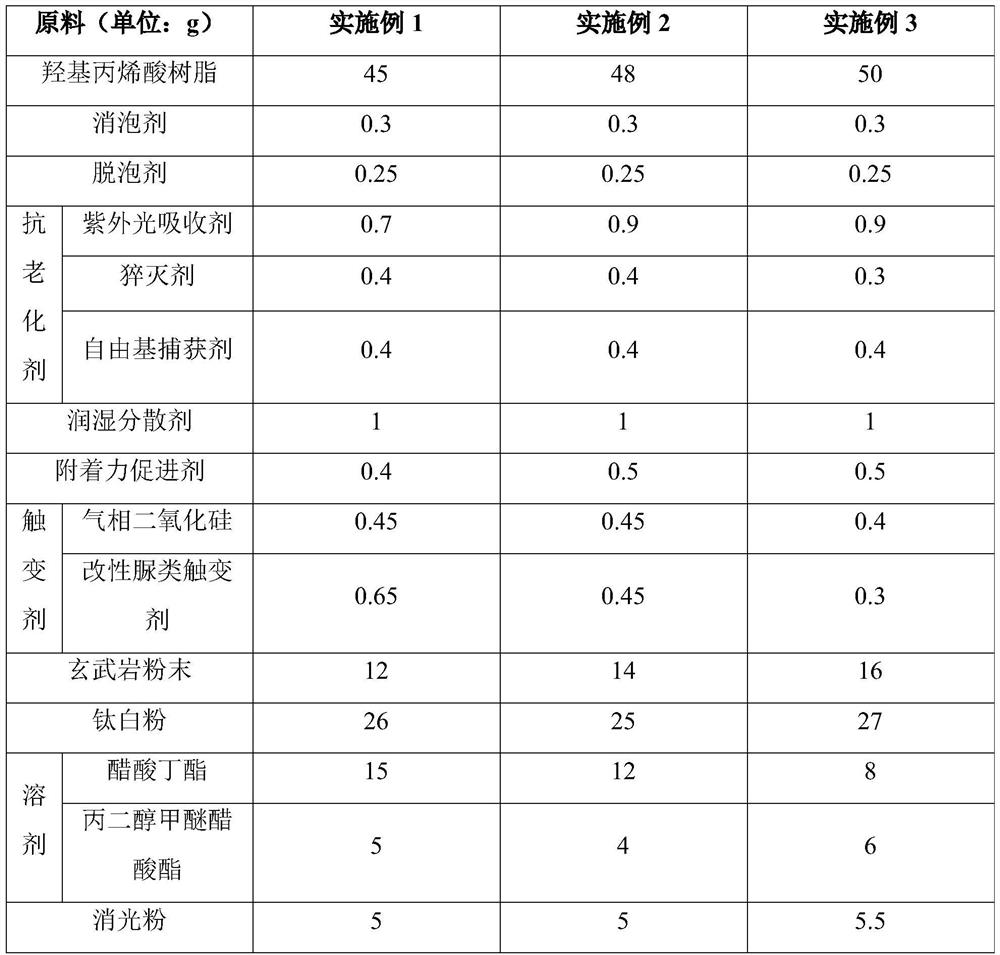

[0059] The preparation method of component A is: basalt is introduced from basalt powder, and hydroxyacrylic resin, defoamer, defoamer, anti-aging agent, wetting and dispersing agent, adhesion promoter, thixotropic agent are mixed according to the ratio in Table 2 Disperse the solvent with a high-speed disperser for 10 minutes (rotating speed 1000r / min), then add basalt powder, titanium dioxide and matting powder, and use a high-speed dispersing machine to uniformly disperse for 20 minutes (rotating speed 3000r / min) to obtain component A. Among them, defoaming The antifoaming agent is a modified silicone resin defoaming agent, the defoaming agent is an organically modif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com